Method for preparing aluminum-base super-amphiphobic surface

A super-amphiphobic surface and aluminum matrix technology, applied in the field of super-amphiphobic surface preparation, can solve the problems of expensive chemical reagents, low processing efficiency, complex devices, etc., and achieve the effect of good non-sticking, low cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Grind the aluminum plate with 1200# and 2000# sandpaper to remove the oxide layer, degrease with detergent, wash with deionized water and blow dry.

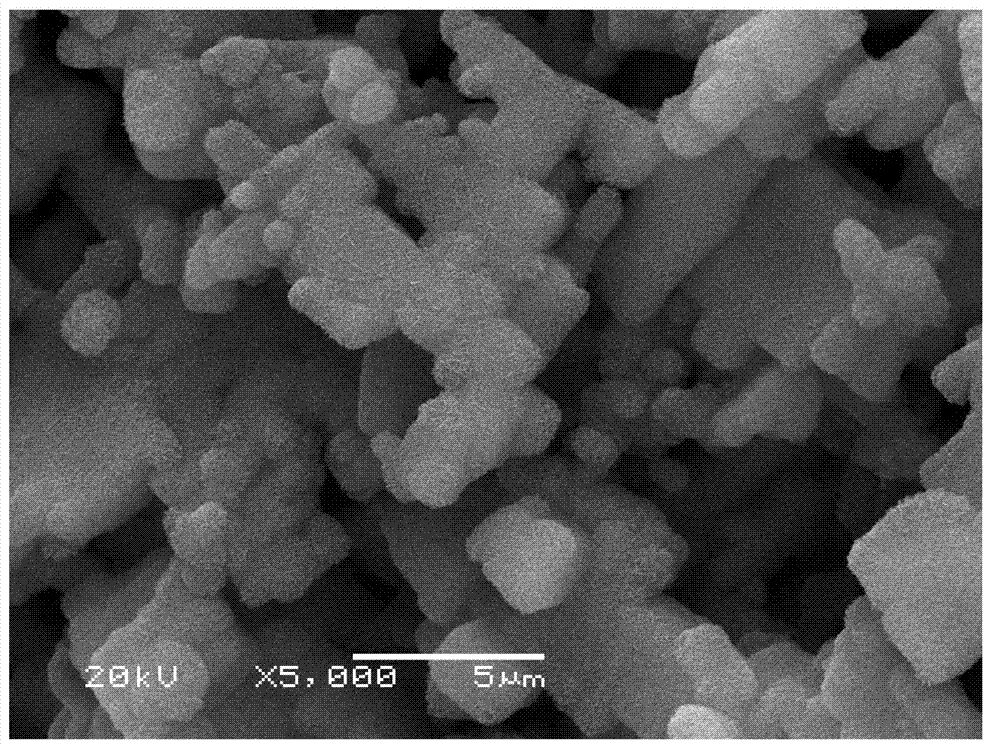

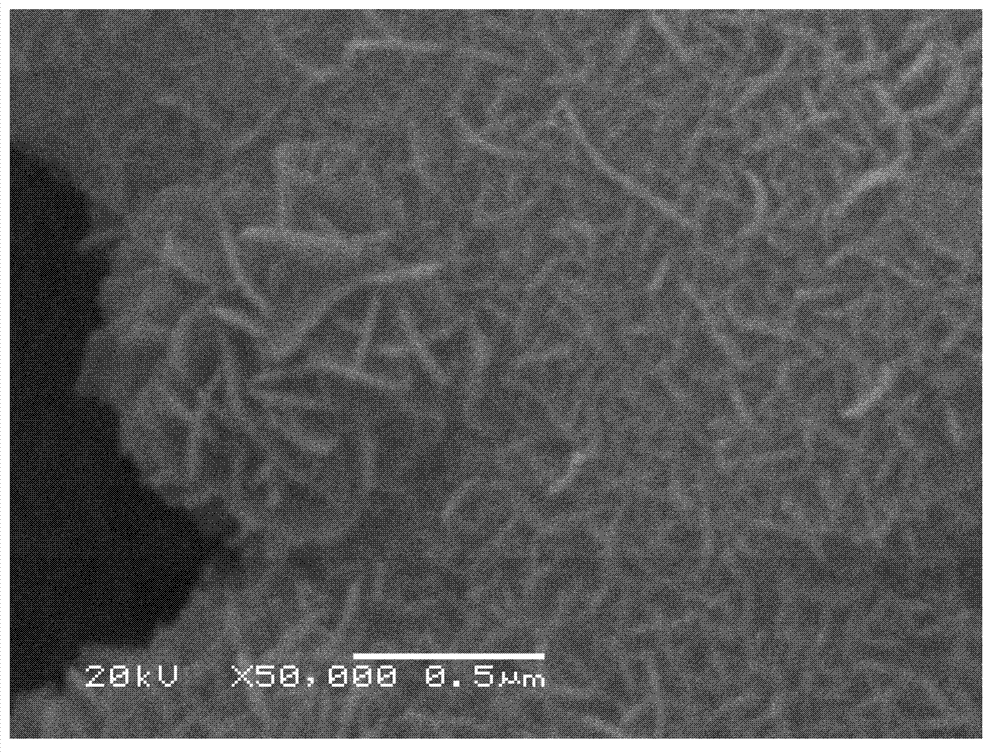

[0022] (2) With an aluminum plate as the anode and a copper plate of the same size as the cathode, place it in 0.1 mol / L NaCl aqueous solution at 500 mA / cm 2 Processing at current density for 6 min. After the electrochemical machining was completed, the aluminum plate was rinsed with deionized water, soaked in boiling water for 40 min, and dried after being taken out.

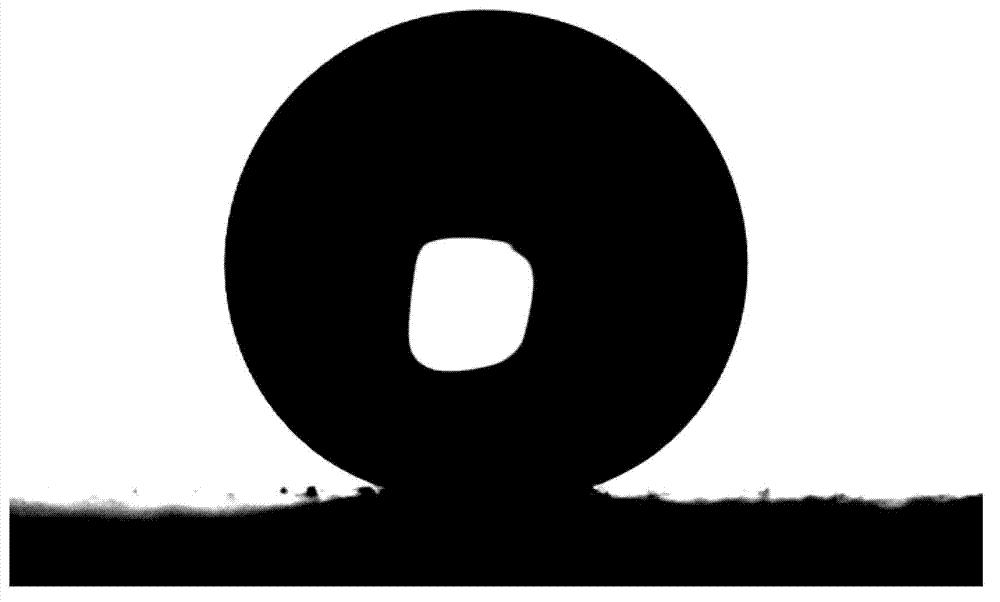

[0023] (3) Soak the processed aluminum plate in 0.015 mol / L perfluorooctanoic acid aqueous solution for 60 min, take it out and blow dry to obtain the superamphiphobic surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com