Three-shaft double-clutch speed changer

A dual-clutch and transmission technology, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as large frictional resistance and reduced transmission efficiency of transmissions, and achieve improved reliability, reduced reserved space, and reduced The effect of the number of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

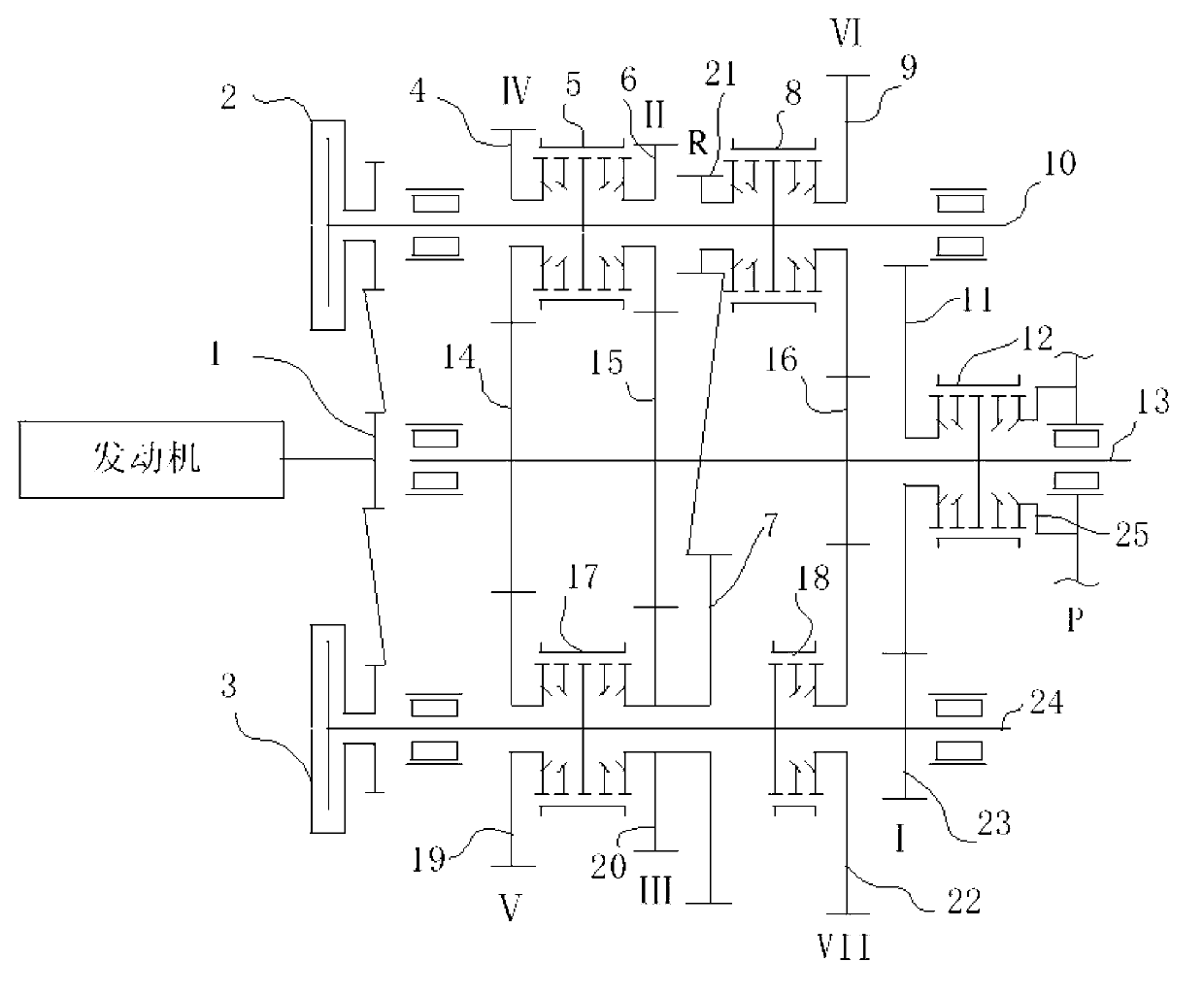

[0015] Embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0016] In this embodiment, the driving gear 1 on the main shaft of the engine rotates together with the engine. Drive the driving side / driven side of the two clutches (the first clutch 3 and the second clutch 2), and the driven side / driving side of the two clutches are respectively connected to the corresponding input shafts. Two input shafts are arranged in parallel at a certain distance, namely the first input shaft 24 and the second input shaft 10 .

[0017] The first gear driving gear 23, the third gear driving gear 20, the fifth gear driving gear 19, the seventh gear driving gear 22 and the reverse driven gear 7 of the odd-numbered gear group are arranged on the first input shaft 24; The second gear driving gear 6, the fourth gear driving gear 4, the sixth gear driving gear 9 and the reverse gear driving gear 21 of the group are arranged on the second in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com