Combined pulverized coal storage and supplying device

A combined, pulverized coal technology, applied in block/powder supply/distribution, fuel supply, combustion method, etc., can solve the problems of small volume, inability to meet large-tonnage boilers, etc., achieve large device capacity, and prevent equipment from blasting. The effect of endangering personal safety and ingenious structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

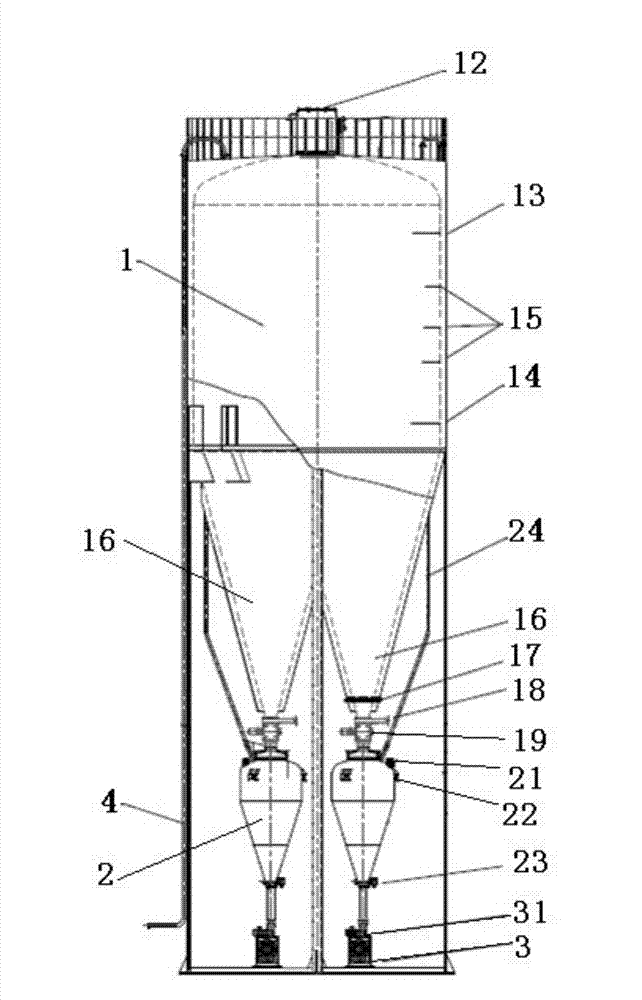

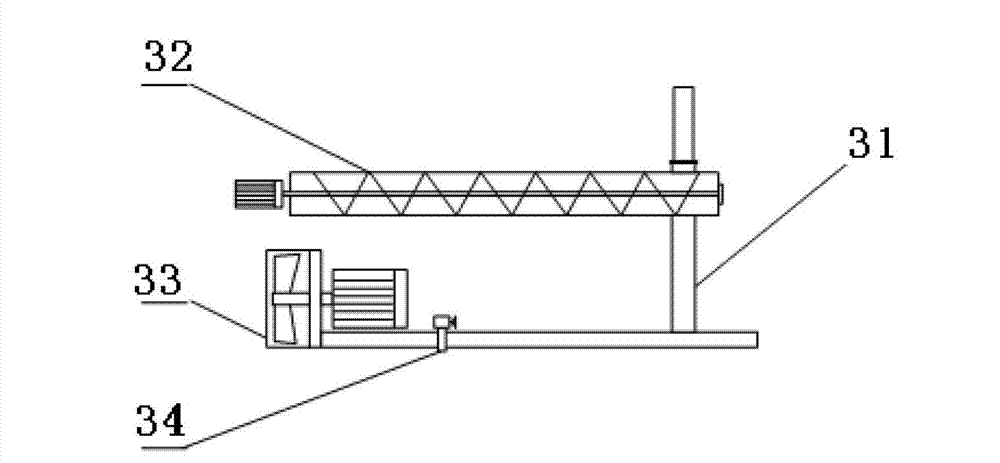

[0015] Such as figure 1 As shown, the present invention mainly includes a powder storage tank (bin) 1, two weighing tanks (bin) 2, two feeders 3 and a pulverized coal powder feeding pipe 4.

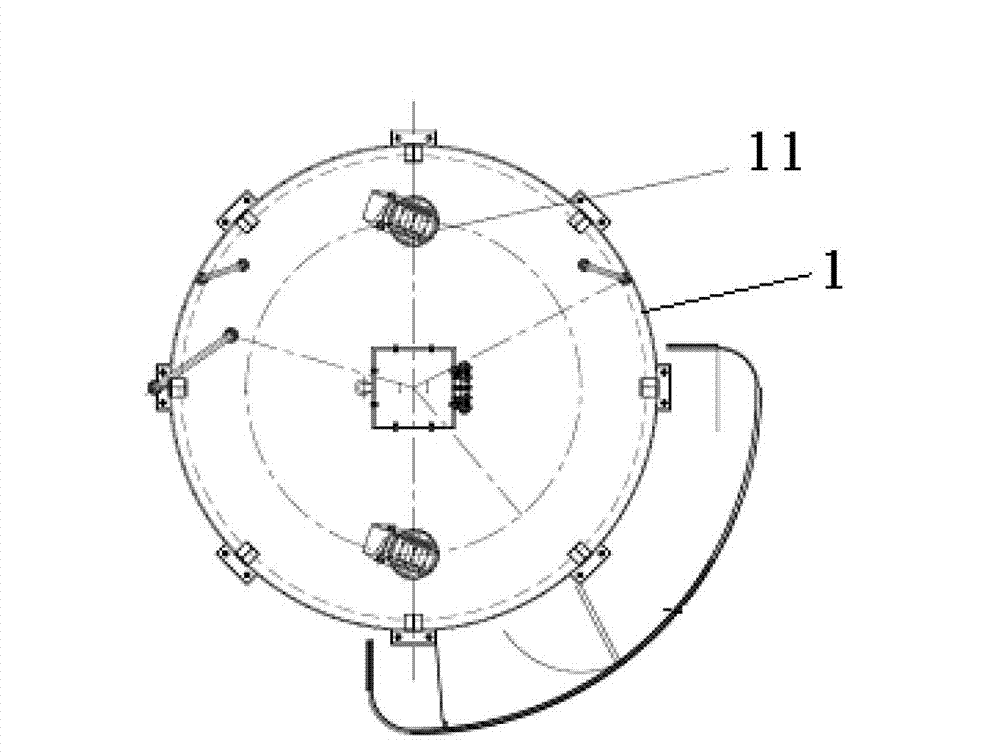

[0016] Such as figure 2 As shown, the powder storage tank 1 top of the present invention is symmetrically provided with two explosion-proof doors 11, as figure 1 As shown, a small bag filter 12 is provided at the center of the inner top of the powder storage tank 1 . A high material level meter 13 is set at the 75% material level on the side wall of the powder storage tank 1, and a low material level gauge 14, a high material level gauge 13 and a low material level gauge are set at the 30% material level position on the side wall of the powder storage tank 1 Three temperature sensors 15 are arranged at intervals on the side wall of the powder storage tank 1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com