Networked on-line inspection method of supersonic gas flowmeter

An ultrasonic flowmeter and inspection method technology, applied in the field of online inspection, can solve the problems of hidden safety hazards and low inspection efficiency, and achieve the effects of ensuring accuracy, low inspection cost, and high degree of informatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

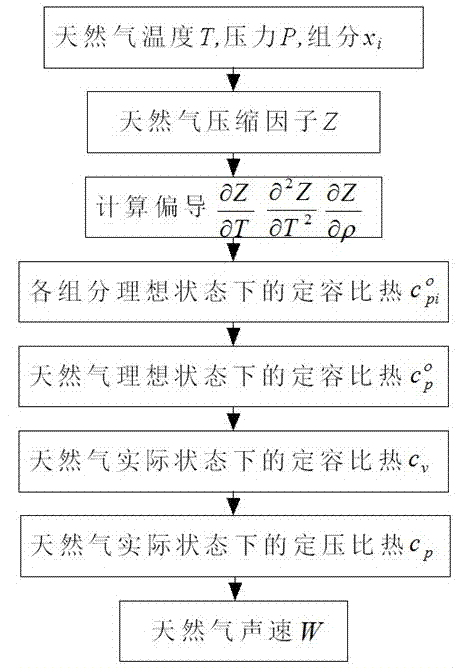

[0021] a) Connect the ultrasonic flowmeter to be inspected to the network platform of Zhejiang Natural Gas Energy Networked Detection System, and establish the basic information of the flowmeter in the database, including model type, manufacturer, serial number, accuracy grade, flow range, and confirm the matching pressure variable transmitter, temperature transmitter and chromatographic analyzer, the accuracy of the pressure transmitter should be better than 0.1%, the accuracy of the temperature transmitter should be better than 0.1 ℃, and the technical performance of the chromatographic analyzer should be Meet GB / T13610-2003, its measurement standard degree should reach 0.05%.

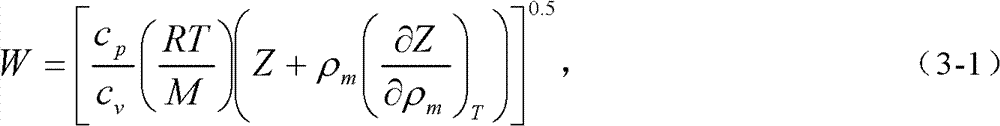

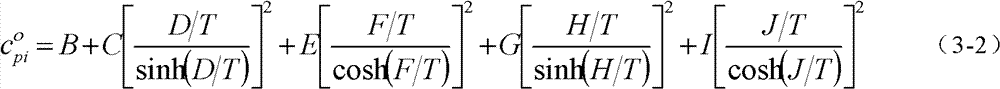

[0022] b) read data through the network platform, the read data includes setting parameters, alarm records, signal gain of each channel, percentage of received signal of each channel, signal-to-noise ratio of each channel, component data, temperature, pressure, Volume flow rate, measured sound veloci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com