Middle-sized rock servo control true triaxial test device

A technology of servo control and test device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of large size span, etc., and achieve the effect of high degree of automation, convenient installation and operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

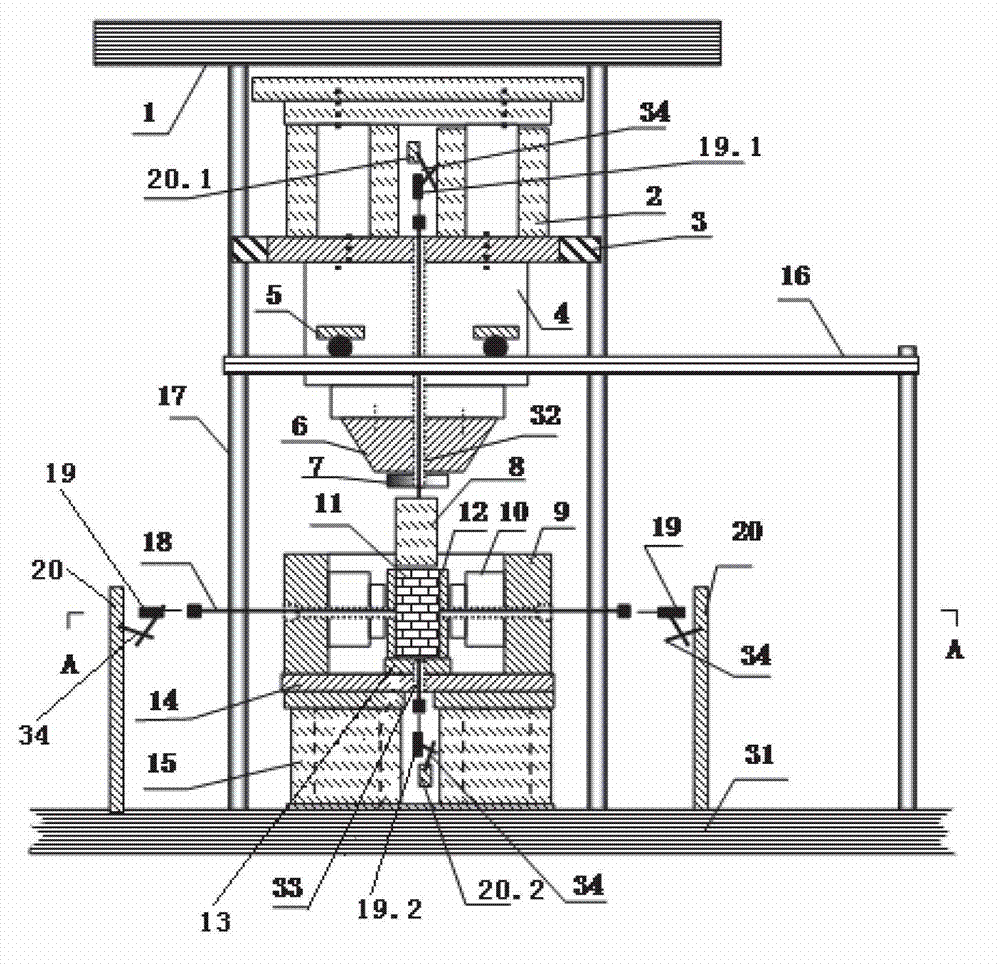

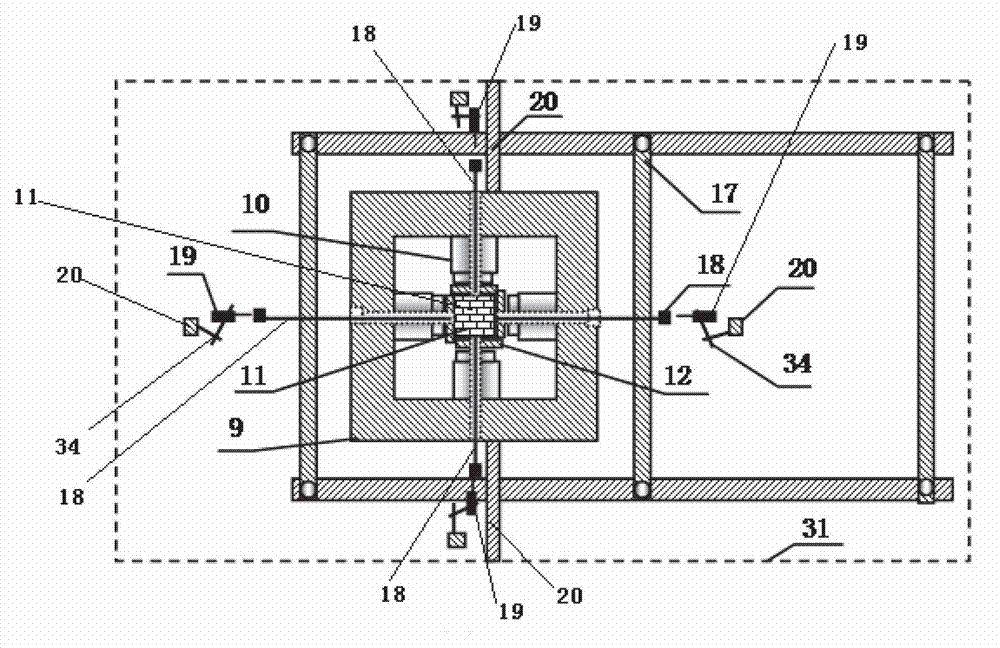

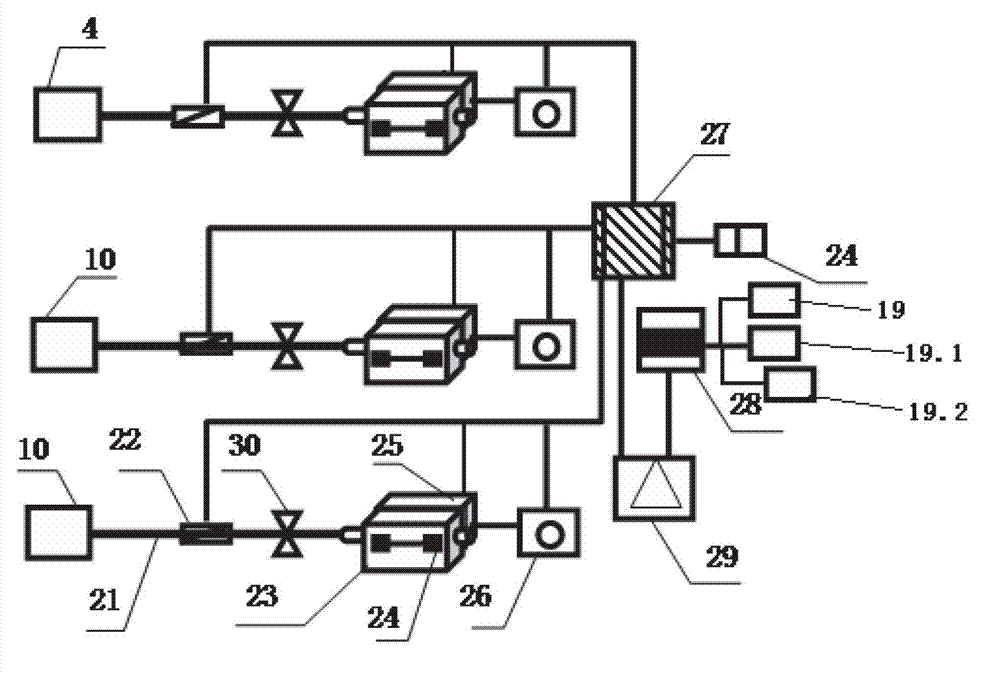

[0026] The invention includes an axial reaction force system, a lateral reaction force system, a servo loading control system, a movement system and a measurement system. Applicable sample size is variable, sample size range: length 80~200mm, width 80~200mm, height 160~400mm; use cavern or steel frame to provide axial reaction force, axial output jack maximum load 12000kN, square The thick-walled hollow steel frame provides lateral reaction force. Four hollow jacks are built in the reaction force frame to act on the side of the specimen respectively, with a maximum load of 4000kN; by changing the size of the six-sided bearing plate of the specimen, various sizes of real In the triaxial test, one end of the stylus passes through a force transmission device with a through hole and the output device directly contacts the center of the surface of the test body 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com