Ball grid array manufactured on printed circuit board

A technology for printed circuit boards and ball grid arrays, applied in the field of ball grid arrays, can solve the problems of wasting printed circuit board area, difficult to reuse ball grid arrays, and labor-intensive ball grid arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

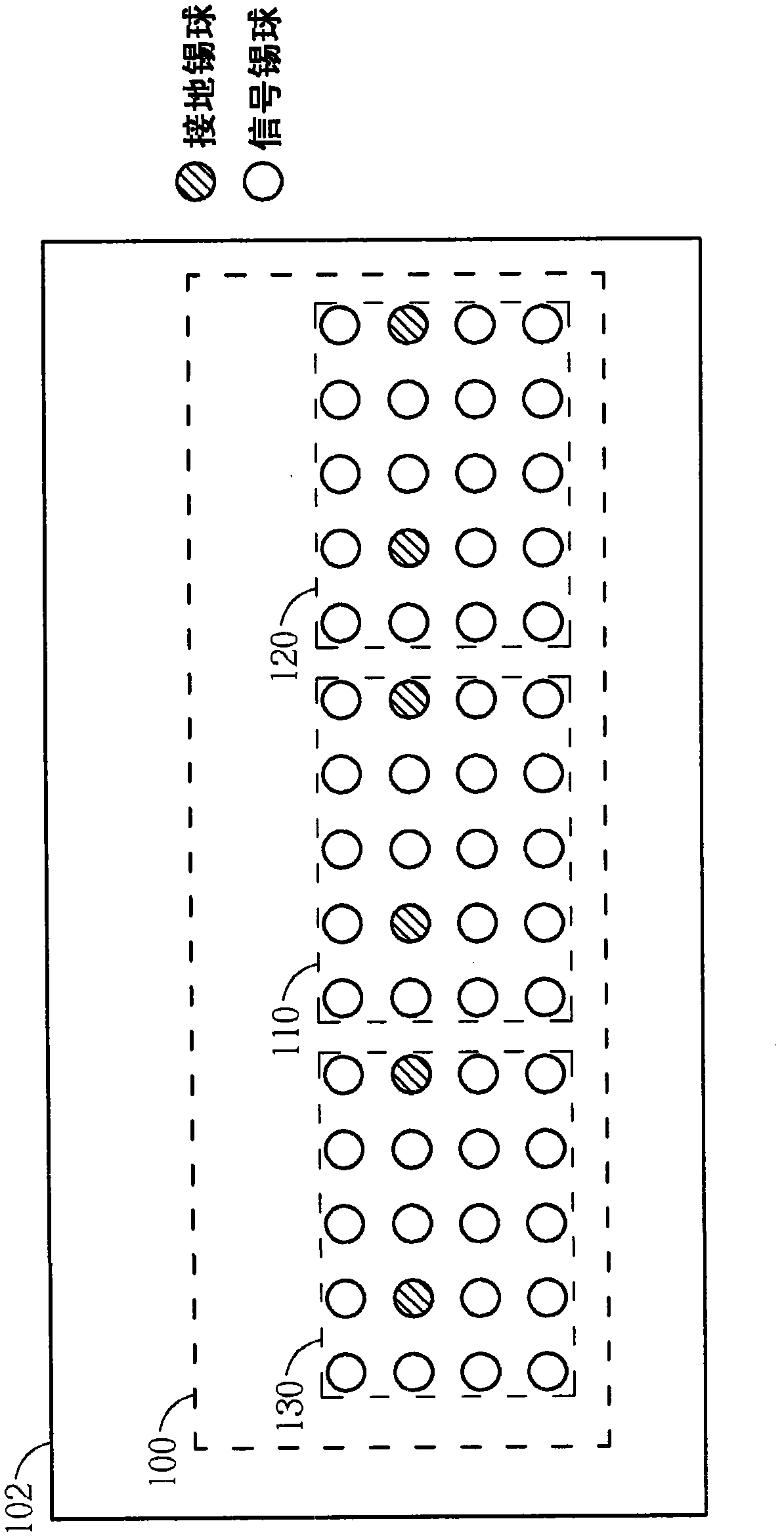

[0019] Please refer to figure 1 , figure 1 It is a schematic diagram of a ball grid array 100 fabricated on a printed circuit board 102 according to an embodiment of the present invention. Such as figure 1 As shown, the ball grid array 100 includes a first solder ball module 110, a second solder ball module 120 and a third solder ball module 130, wherein the first, second and third solder ball modules 110, 120, 130 have The same solder ball arrangement pattern. Each solder ball module includes twenty solder balls arranged in a 4*5 array, that is, each row of each solder ball module has five solder balls, and each row (column) has four solder balls. Only two solder balls in each solder ball module are grounded, and the two grounded solder balls are located in the third column of the solder ball module. The first column of the solder ball modules (ie, the lowest column of the ball grid array 100 ) faces the signal input lines input to the solder ball modules on the printed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com