Method and arrangement for driving a microphone

A microphone and generator technology, applied in electrostatic transducer microphones, amplifiers with semiconductor devices/discharge tubes, amplifiers, etc., to achieve the effect of eliminating overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

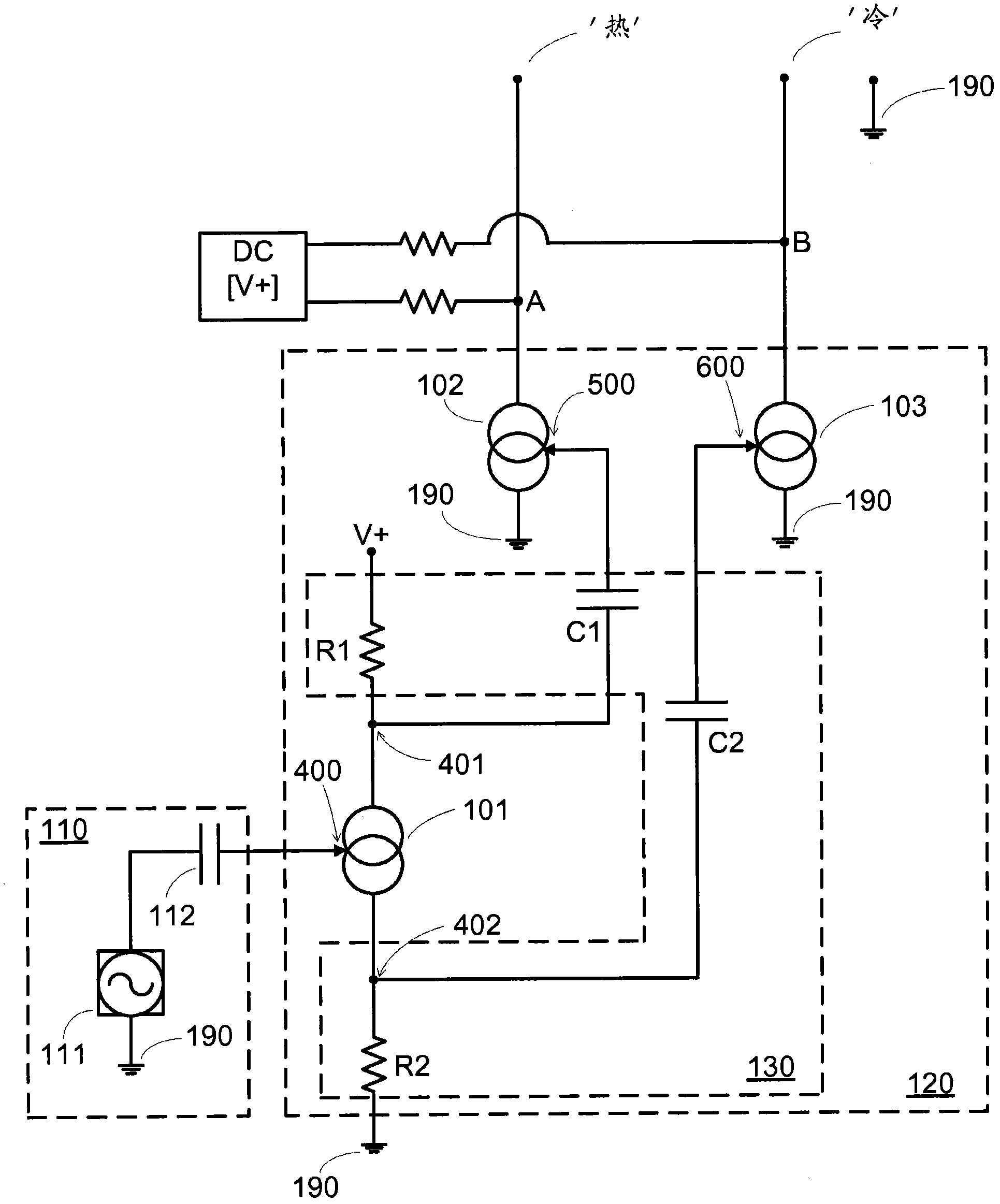

[0013] figure 1 A differential microphone preamplifier 120 implemented in accordance with an exemplary embodiment of the present invention and coupled to a microphone (MIC) 110 is shown. The differential microphone preamplifier 120 and the microphone (MIC) 110 are in one embodiment of the invention housed in the same housing, which is not shown in the figure. Furthermore, the microphone 110 may have additional signal amplification circuits which are not shown here for the sake of clarity. In operation, by virtue of its structure, a signal voltage is generated by the microphone element 111 of the microphone 110 and fed to the input 400 of the microphone preamplifier circuit 120 via the input coupling capacitor 112 . That is, the signal voltage is generated as a potential difference between the signal ground potential 190 and the voltage potential generated by the microphone element 111 . The microphone preamplifier circuit 120 will be described in more detail below, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com