Aerial fog cooling process method of hot rolling bar

An aerosol cooling and bar technology, which is applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of reduced bar strength, coarse texture and grain, and easy blistering on the surface of the bar, and achieves comprehensive mechanics. Improved performance, reduced chance of rusting, improved surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

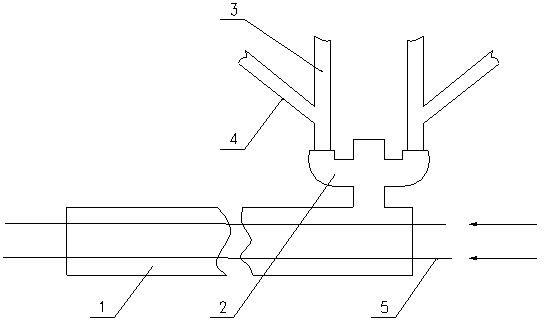

[0016] see figure 1 , a gas mist cooling process for hot-rolled bars in the present invention, which cools the hot-rolled bars rolled by the finished product stand through a controlled cooling system, and the controlled cooling system includes a controlled cooling device, a water supply system and an air supply system, the control cooling device is installed between the finished frame and the cooling bed, it includes a box 1, the box 1 is set above the rolling line 5, and the top of the front end of the box 1 is provided with an aerosol joint 2. The aerosol joint 2 has two interfaces, the two interfaces are connected with an air inlet pipe 3, and the air inlet pipe 3 is connected with a water inlet pipe 4, and the air inlet pipe 3 and the water inlet pipe 4 are both Adopt metal flexible pipe, the inner diameter of described air inlet pipe 3 is 32mm, the inner diameter of described water inlet pipe 4 is 25mm, and described water supply system is connected with water inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com