Material shaft of coiling machine

A material shaft and rolling machine technology, applied in the field of material shafts, can solve the problems of difficulty in ensuring the coaxiality of the material and the material shaft, inconvenient disassembly and assembly of materials, and easy wrinkling of components, and achieves a reasonable and compact structure and easy assembly and disassembly. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

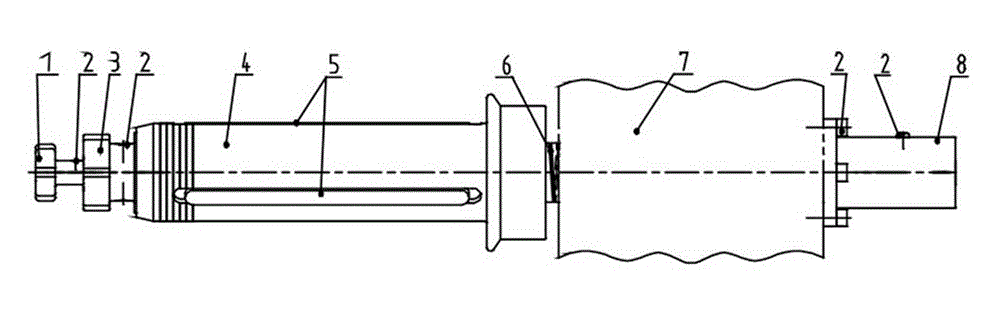

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The material shaft of a coiling machine in the present invention is mainly composed of two parts: a three-claw expansion mechanism and a material axial position adjustment mechanism, which respectively realize automatic centering and fixing of materials of different widths, rotation and adjustment of the material axial position. Great function. Such as figure 1 As shown, the expansion adjustment wheel 3 is fixed by the screw 2, and the material bushing 4 and the expansion adjustment wheel 3 are nested and installed, and can be rotated relative to each other. Manually rotate the expansion and tightening adjustment wheel 3 clockwise during loading, and through the threaded pair and the expansion claws 5, the three expansion claws 5 are simultaneously opened under the limit guide action of the three key grooves of the material shaft sleeve 4, and the three expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com