Multi-hole push-pull die busbar punching machine

A punching machine and drawing die technology, applied in the field of multi-hole push-pull die busbar punching machines, can solve the problems of large overall structure of the cantilever, unsupported long busbars, complicated manufacturing of the turntable, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

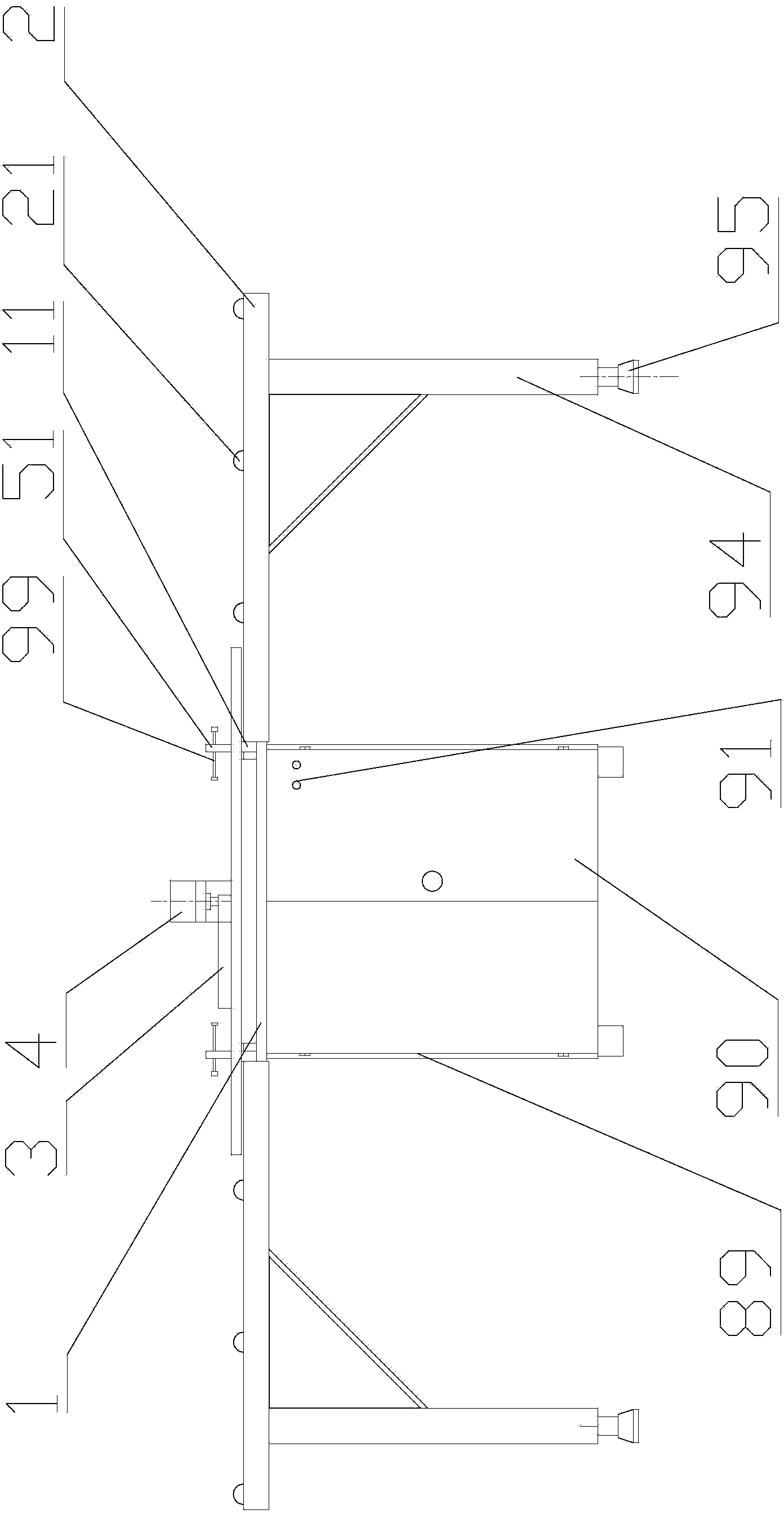

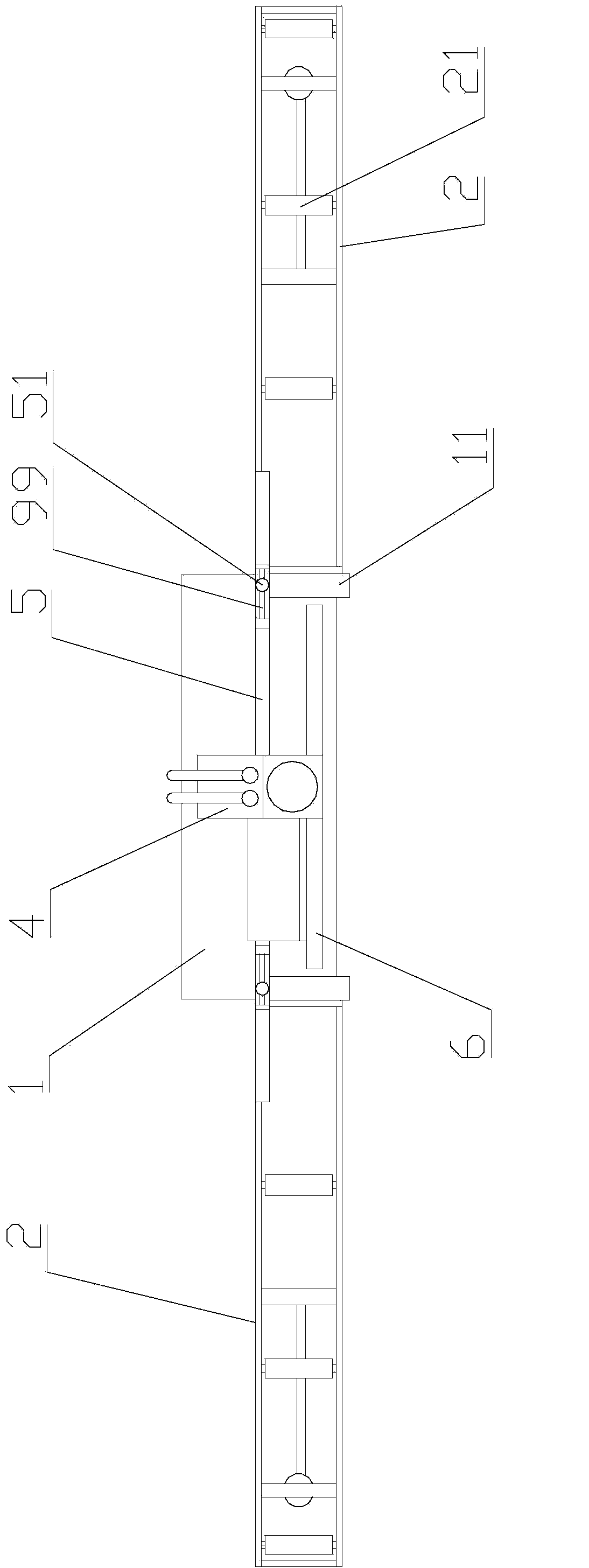

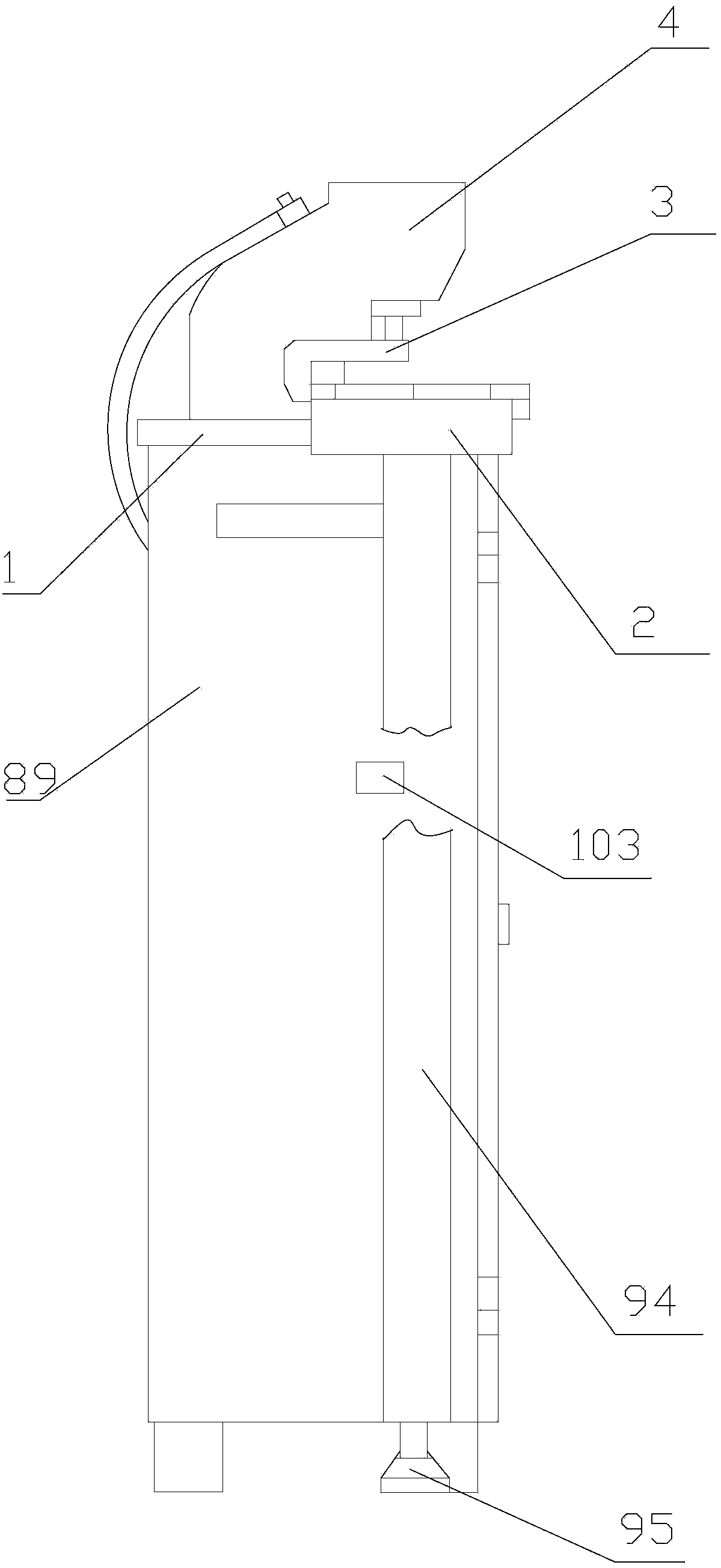

[0033] Such as Figure 1~3 , 9 to 14: it includes a platen 1, a bracket 2, a porous push-pull die 3, a cylinder arm 4, a stop sight ruler 5, an X-direction sight ruler 6, a Y-direction sight ruler 7, a T-shaped punch 47,

[0034] The platen is a flat plate, and a ruler base 11 is respectively arranged on the left and right sides of the platen, and the ruler base is fixed on the platen, and a cross groove 12 is arranged in the ruler base; the main function of the platen is to support other components , such as ruler base, cylinder arm, bracket, etc.;

[0035] Described support 2 has two, is plane frame type, is respectively connected on the ruler seat 11 that is provided with on the both sides of platen, and the frame structure is provided with several auxiliary busbar conveying rollers 21; Support is the extension of platen , the purpose is to support the busbar beyond the platen. In order to ensure the smooth conveying of the busbar, sliding rollers are generally set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com