Construction lift for building under construction

A technology for construction lifts and buildings, applied in lifts, transportation and packaging, etc., can solve problems such as potential safety hazards of equipment, broken guide rails, damaged connecting bolts, etc., and achieve the effect of avoiding uncomfortable feelings or injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

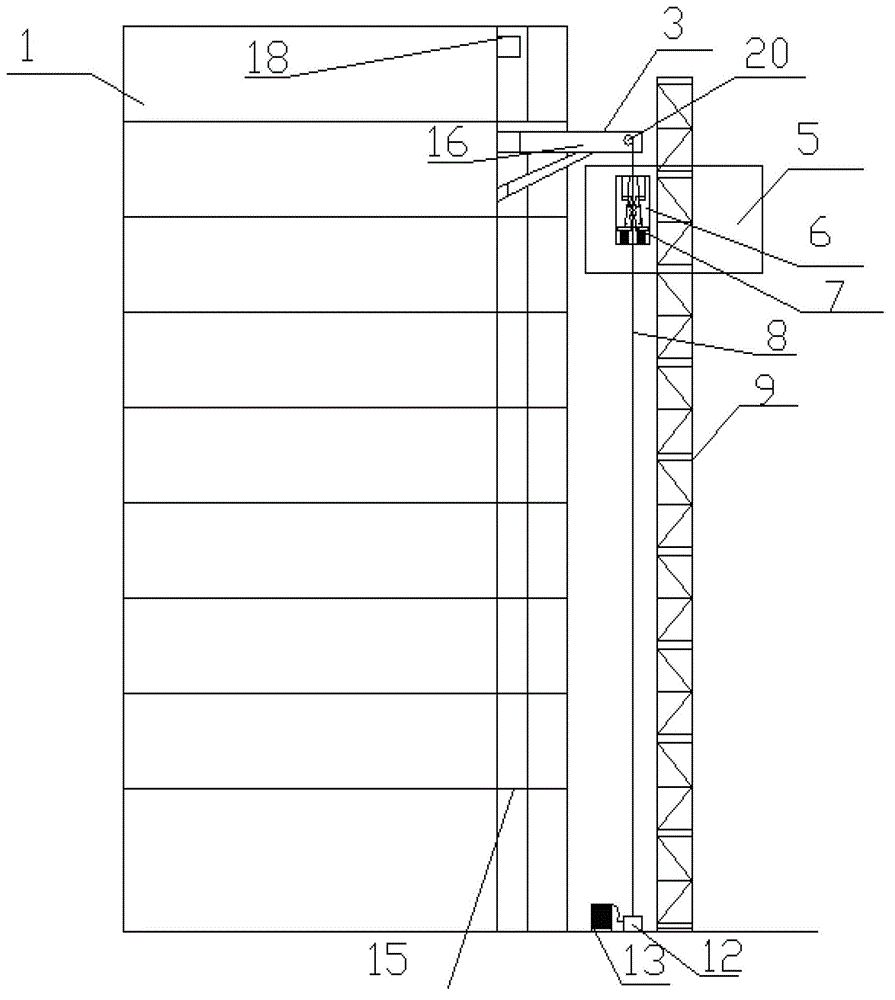

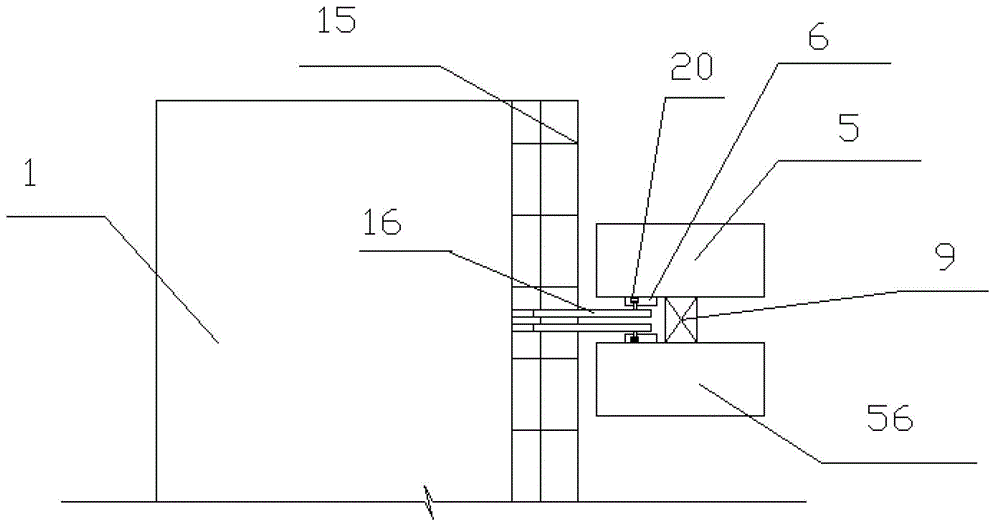

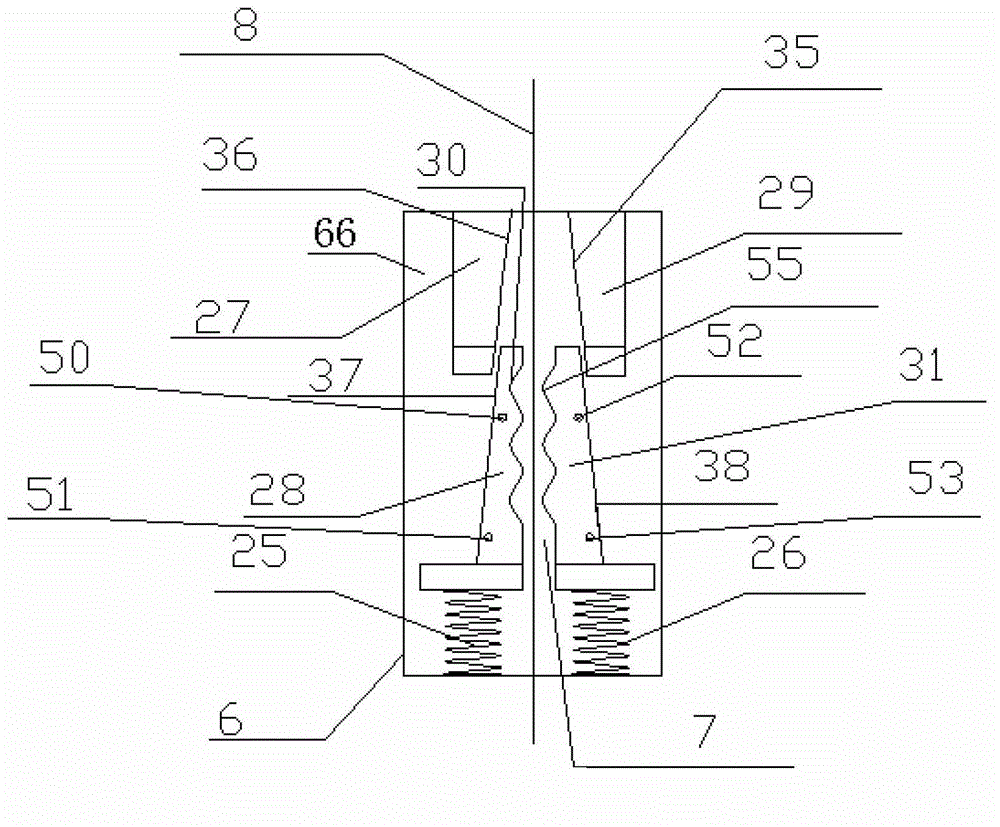

[0022] Such as figure 1 As shown, a construction elevator includes a guide rail frame 9 and a ladder cage 5. The anti-drop system includes a rope grabbing device 6 and a safety rope 8. The rope grabbing device 6 is arranged on the ladder cage 5 of the construction elevator. One end of the safety rope 8 is connected to the top of the building 1 or to the support structure 3 fixedly connected to the top of the building 1, and the above-mentioned safety rope 8 extends downwards through the inner hole 7 of the grab rope device 6 arranged on the ladder cage 5 and is fixed. On the foundation 12 on the ground, the above-mentioned rope grabbing device 6 is set on the outside of the safety rope 8 and can be lifted and lowered freely on the guide rail frame 9. When the rope grabbing device 6 is activated when necessary, the ladder cage 5 is firmly fixed by the rope grabbing device 6 Safety rope 8. The safety rope 8 can prevent the ladder cage 5 from falling or the ladder cage 5 from ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com