Novel explosion-proof glass

An anti-explosion, glass technology, applied in glass/slag layered products, chemical instruments and methods, layered products, etc., can solve the problems of glass fragments splashing, injury and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

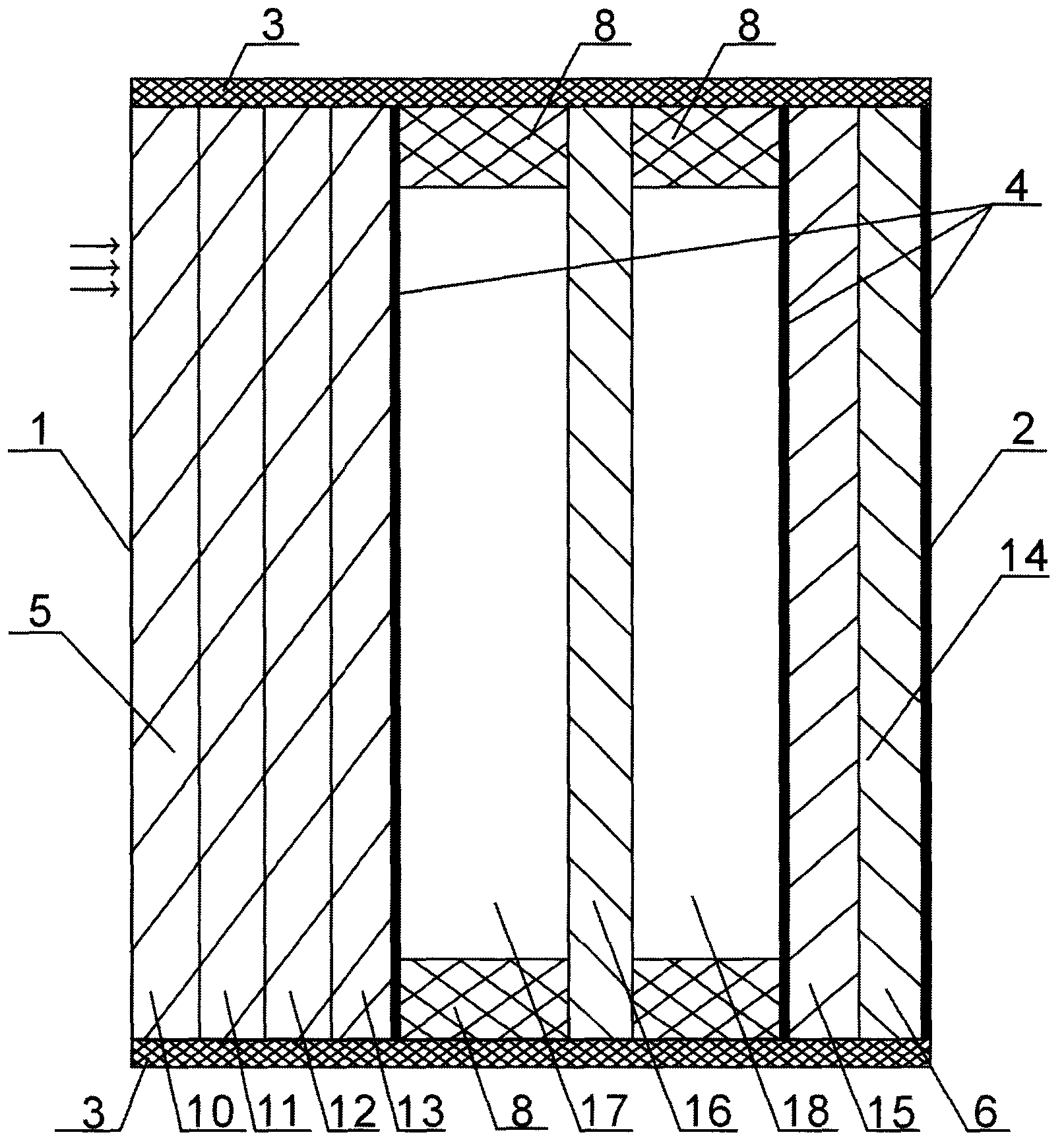

[0019] Embodiment one: refer to figure 1 As shown, the explosion-proof glass of the present invention has an impact layer 1 and a protective layer 2, and the upper and lower sides of the impact layer 1 and the protective layer 2 are sealed into one structure by a sealing member 3, and the sealing member 3 is made of hot melt adhesive or glass glue or not. A sealant strip made of adhesive such as dry glue; the side surfaces of the impact layer 1 and the protective layer 2 are covered with an explosion-proof film 4 . The impact layer 1 adopts bulletproof composite glass 5, which is four layers, and it is composed of the first layer of glass 10, the second layer of glass 11, the third layer of glass 12, and the fourth layer of glass 13. Of course, the glass The number of composite layers can also be set as two layers or three layers or other layers. The protective layer 2 adopts laminated glass 14, and the laminated glass 14 is composed of the fifth layer of glass 15 and the fir...

Embodiment 2

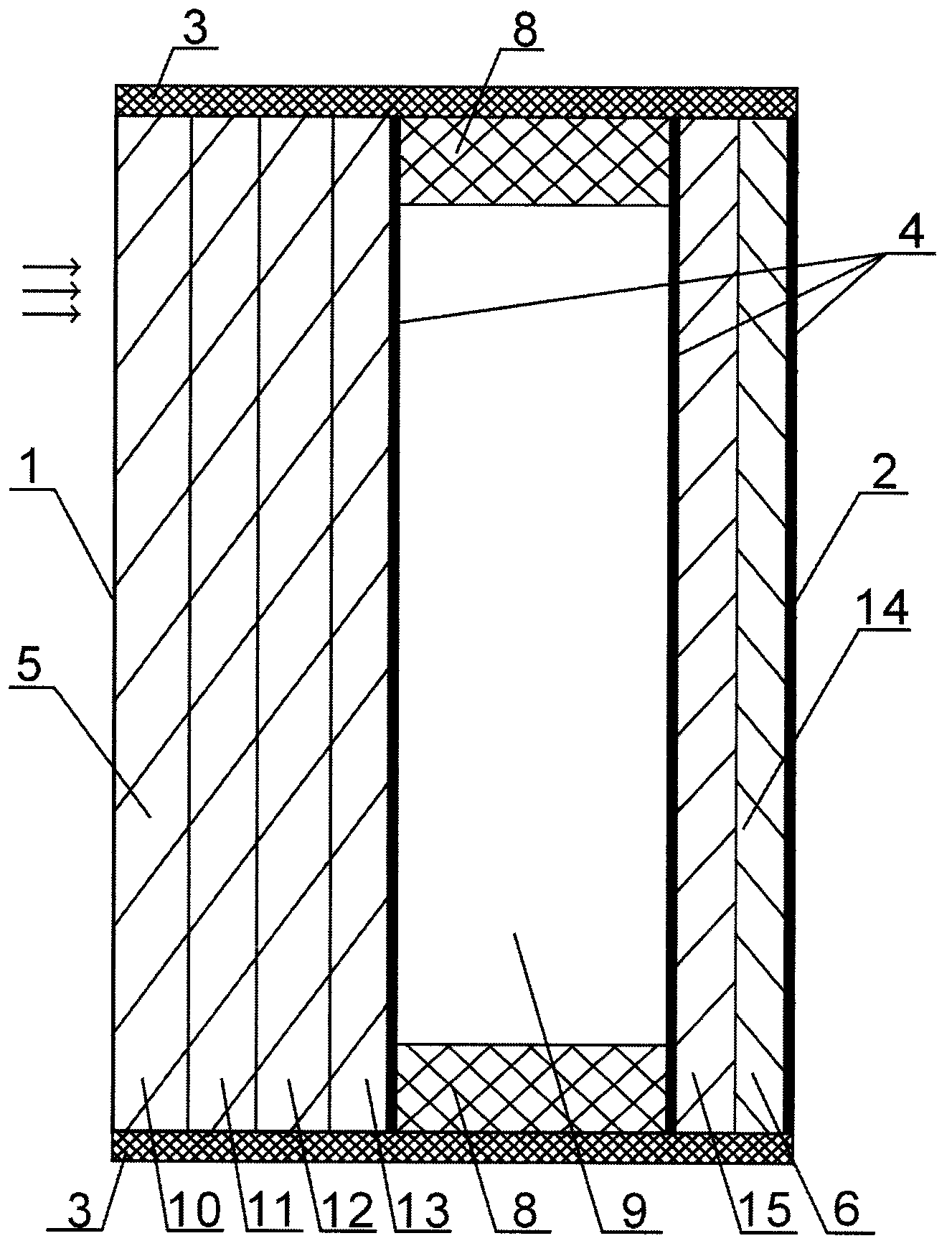

[0020] Embodiment two: refer to figure 2 As shown, the explosion-proof glass has an impact layer 1 and a protective layer 2, and the upper and lower sides of the impact layer 1 and the protective layer 2 are sealed into one structure by a seal 3; the side surfaces of the impact layer 1 and the protective layer 2 are covered with an explosion-proof film 4 . The impact layer 1 adopts bulletproof composite glass 5, which consists of four layers, consisting of the first layer of glass 10, the second layer of glass 11, the third layer of glass 12, and the fourth layer of glass 13. The number of layers can also be set as two layers or three layers or other layers. Described protective layer 2 adopts laminated glass 14, and laminated glass 14 is formed by compounding of fifth layer of glass 15 and first layer of rubber sheet 6, and buffer member 8 is arranged between bulletproof composite glass 5 and laminated glass 14, between the two A buffer cavity 9 is formed by the buffer mem...

Embodiment 3

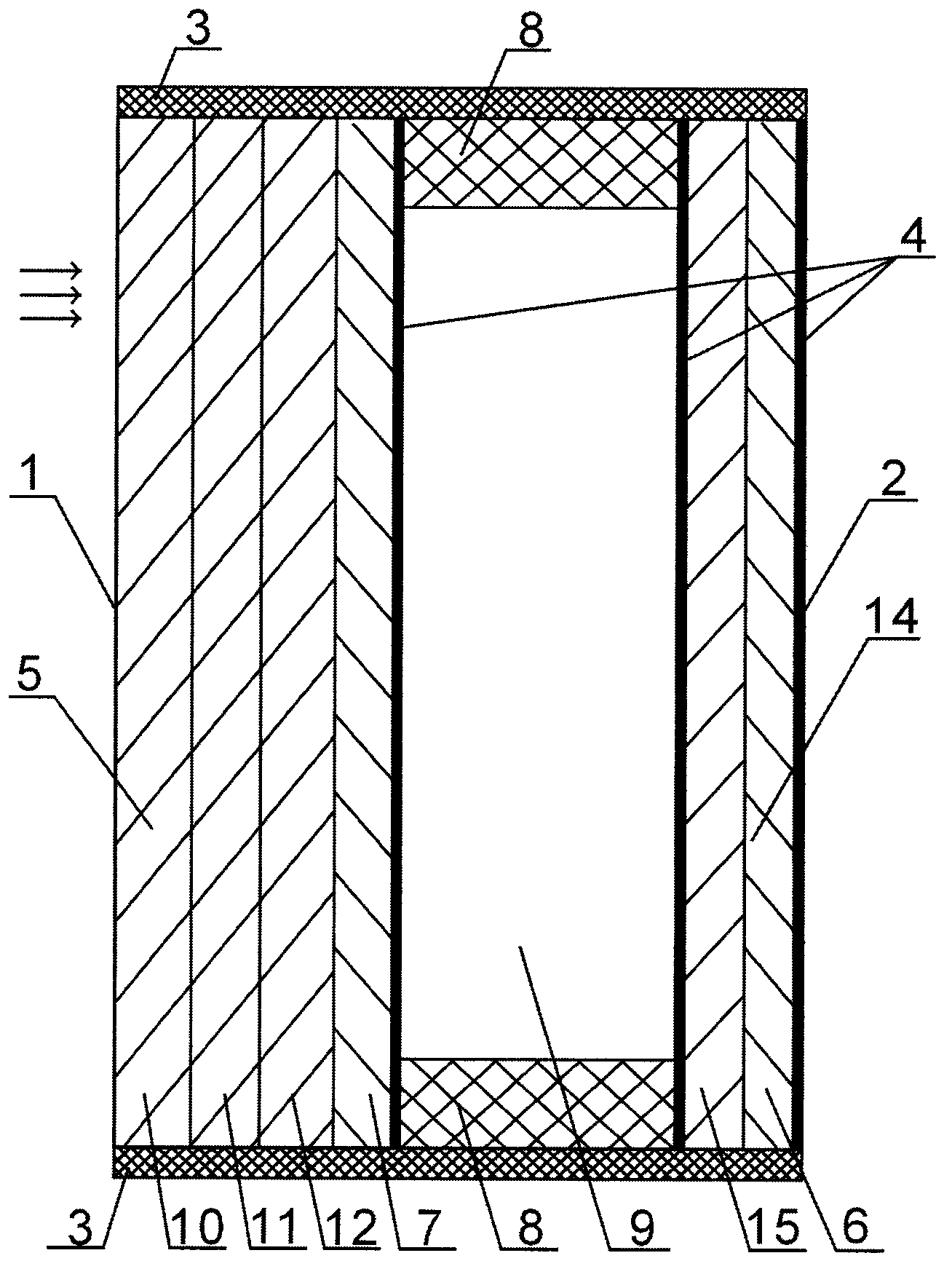

[0021] Embodiment three: refer to image 3 As shown, the explosion-proof glass has an impact layer 1 and a protective layer 2, and the upper and lower sides of the impact layer 1 and the protective layer 2 are sealed into one structure by a seal 3; the side surfaces of the impact layer 1 and the protective layer 2 are covered with an explosion-proof film 4 . The impact layer 1 adopts reinforced bulletproof composite glass 5, and the reinforced bulletproof composite glass 5 consists of four layers, which are compounded by gluing the first layer of glass 10, the second layer of glass 11, the third layer of glass 12 and the third layer of rubber sheet 7 Composition, wherein the third layer of plastic sheet 7 can be set at any position between the first layer of glass 10, the second layer of glass 11, and the third layer of glass 12, and can also be arranged on the first layer of glass 10, the second layer of glass The left side or the right side of glass 11, third layer of glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com