Flat-head truck cab grille capable of absorbing impact kinetic energy

A cab and flat head technology, applied to bumpers, radiators, etc., can solve the problems of inability to effectively reduce injuries to drivers and occupants, inability to absorb impact kinetic energy, and absorption of impact kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

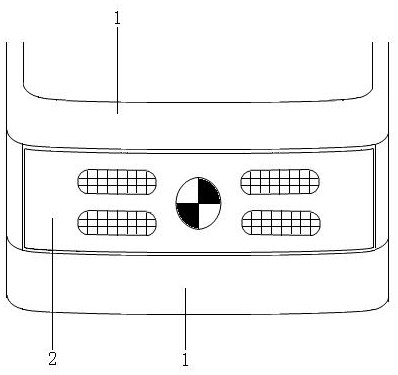

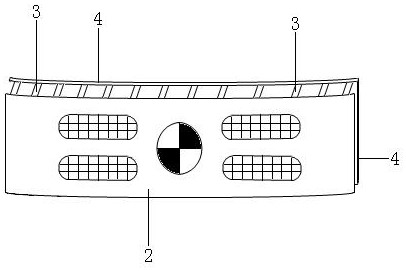

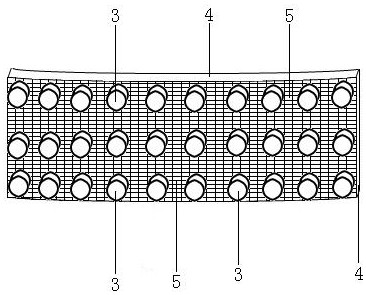

[0013] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

[0014] A center grille in the driver's cab of a truck that can absorb impact kinetic energy is characterized in that it includes a body 1, a center grille 2, a buffer pad 3, a buffer plate 4, and a steel wire mesh 5;

[0015] The vehicle body 1 is in the shape of a hollow cuboid, and a buffer plate 4 is arranged horizontally and vertically in the middle of the lower front through multi-point connections of bolts;

[0016] The buffer plate 4 is a rectangular shape formed by high-density resin thermocompression, and the front interior is hot-pressed and fused with a grid-like steel wire mesh 5, and the front of the buffer plate 4 is bonded with a plurality of hollow holes horizontally and vertically by resin glue. Disc-shaped rubber buffer pad 3, the rear of the buffer plate 4 is horizontally provided with a plurality of elongated rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com