Device capable of realizing continuous constant flow pumping of concrete and control method of device

A constant flow, concrete technology, which is applied to components of pumping devices for elastic fluids, pump control, fluid pressure actuators, etc., can solve the problem of concrete backflow, unstable pumping flow, and inability to achieve constant flow pumping and other problems, to achieve the effect of eliminating shock vibration and constant concrete pumping volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

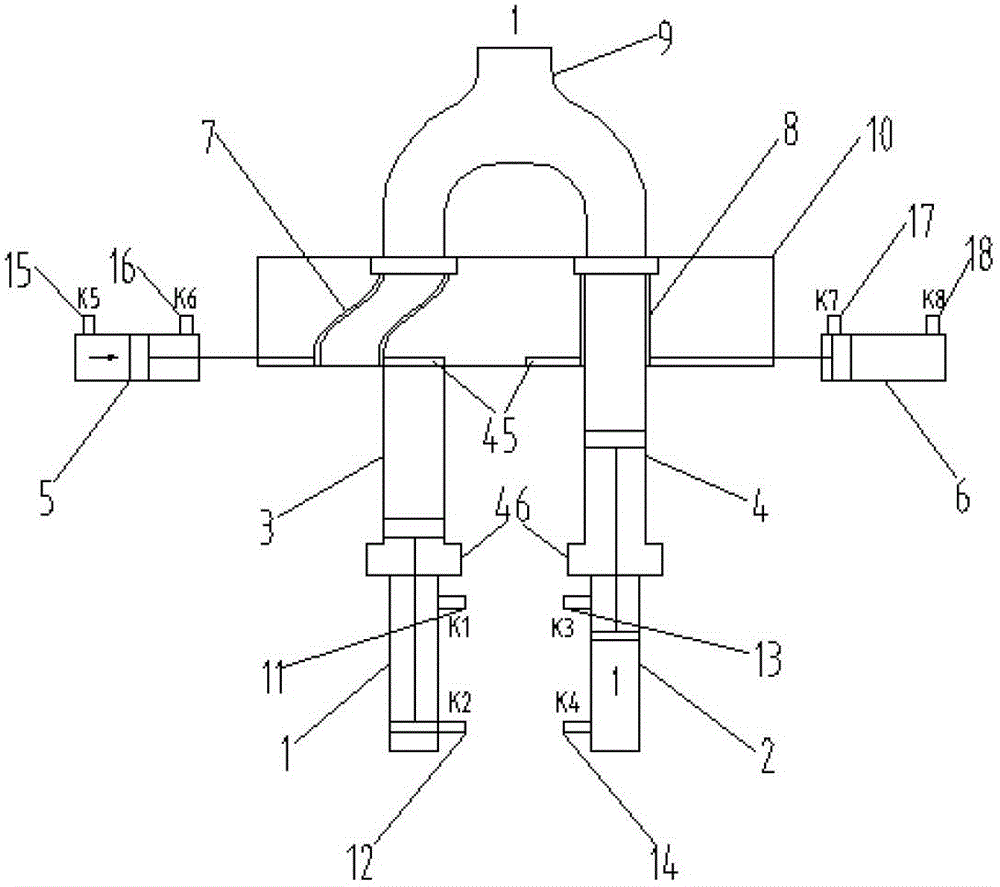

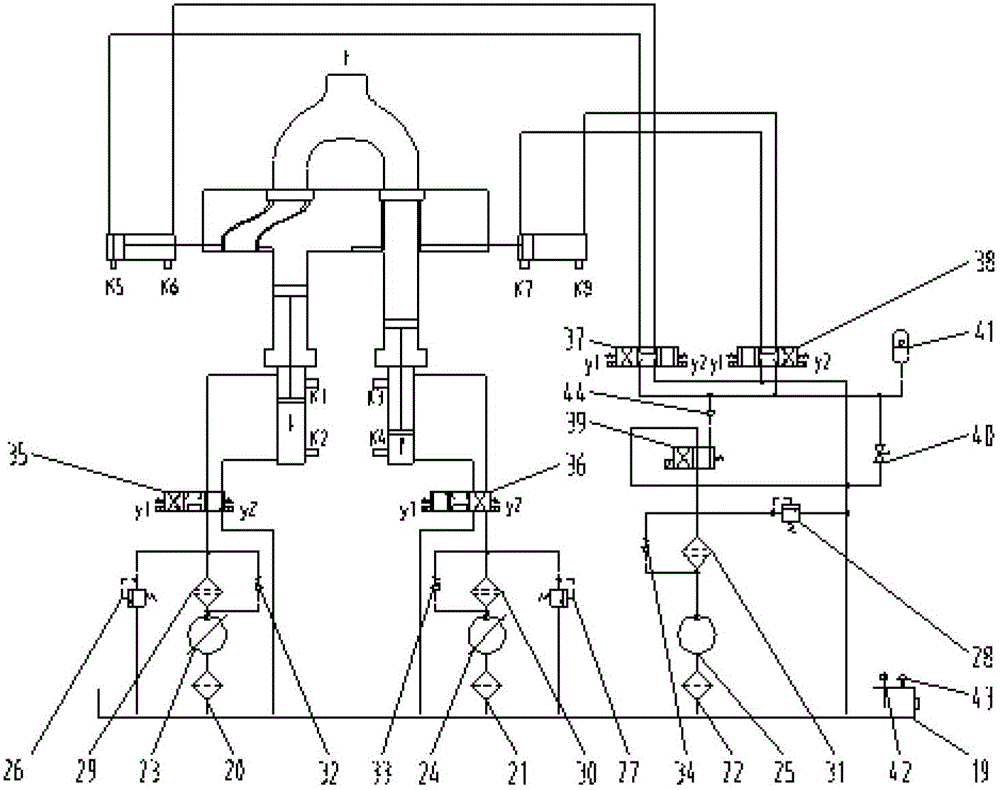

[0097] Such as Figure 5 to Figure 12 Shown is a schematic diagram of the working process of the continuous constant flow pumping system based on the S-shaped valve. Start working position with the left pumping cylinder 3 starting to suck material. The left distributing valve oil cylinder 5 is in the left position, the left pumping cylinder 3 communicates with the hopper 10, the left main oil cylinder 1 has a rod cavity to feed oil, and the left pumping system is in the suction working condition. After the ts2 acceleration time, the left pumping system enters a period of t2 constant speed suction process, when the K2 travel switch 12 of the left main cylinder 1 is triggered, the left pumping system starts to end the suction working condition, and ends after the ts1 deceleration time Suction. In order to ensure that the suction is completely completed, wait for tw1 time after ts1. After the time tw1 ends, the rodless chamber of the left distributing valve oil cylinder 5 ente...

Embodiment 2

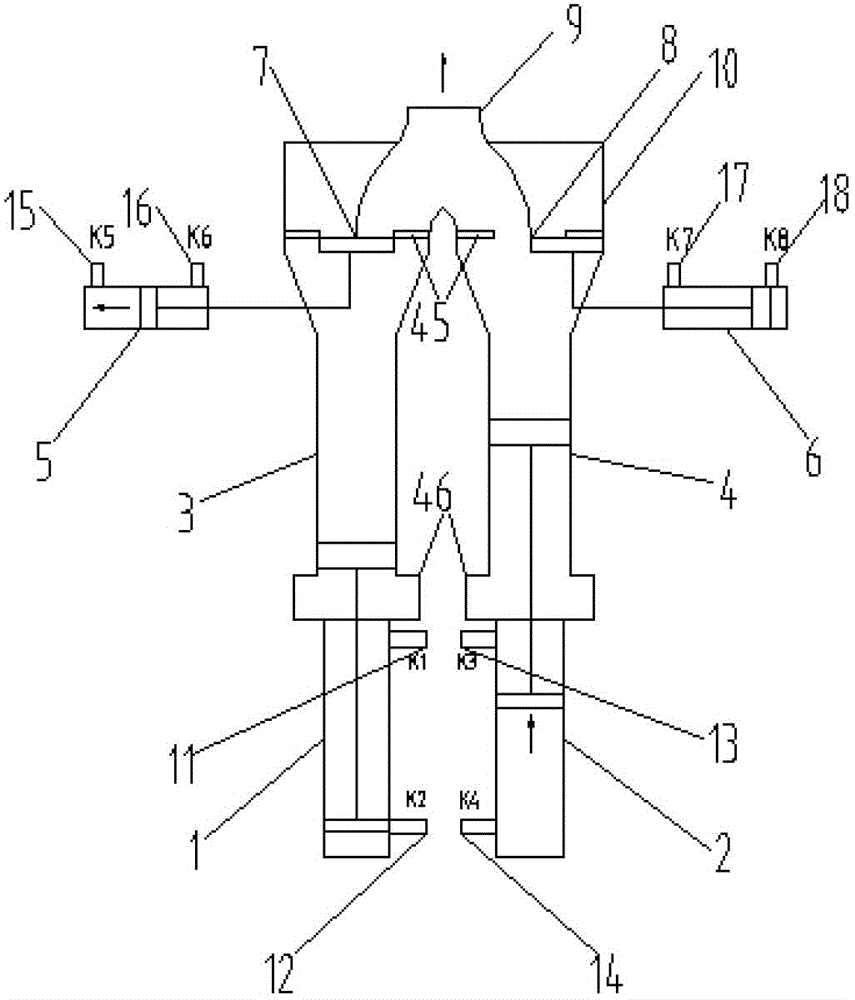

[0099] Such as Figure 14 to Figure 21 Shown is a schematic diagram of the working process of the continuous constant flow pumping system based on the gate valve. The working principle and process of the continuous pumping device using gate valves are basically the same as those using S-shaped valves. Start with the left pumping cylinder 3 starting to suck material. The left distributing valve oil cylinder 5 is in the right position, the left pumping cylinder 3 communicates with the hopper 10, the left main oil cylinder 1 has a rod cavity to feed oil, and the left pumping system is in the suction working condition. After the ts2 acceleration time, the left pumping system enters a period of t2 constant speed suction process, when the K2 travel switch 12 of the left main cylinder 1 is triggered, the left pumping system starts to end the suction working condition, and after the ts1 deceleration time, the suction ends material. In order to ensure that the suction is completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com