Heat-dissipation structure of light-emitting diode (LED) daylight lamp

A technology of LED fluorescent lamp and heat dissipation structure, which is applied in the field of lighting, can solve the problems such as the difficulty of formulating LED fluorescent lamp standards, the difficulty of ensuring the safety of actual use, and the difficulty of ensuring safety, so as to avoid electric shock, meet the temperature requirements, and reduce the area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

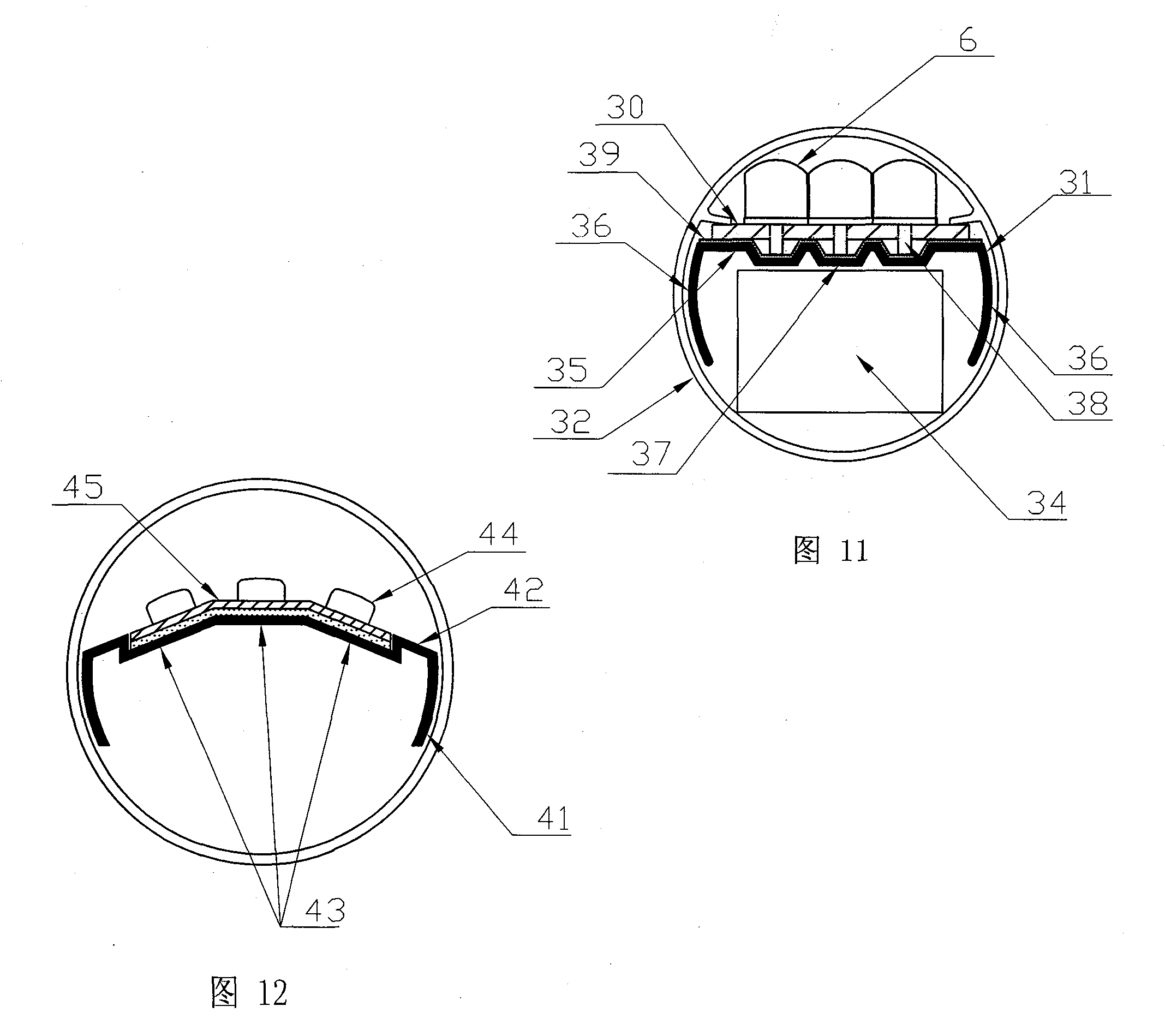

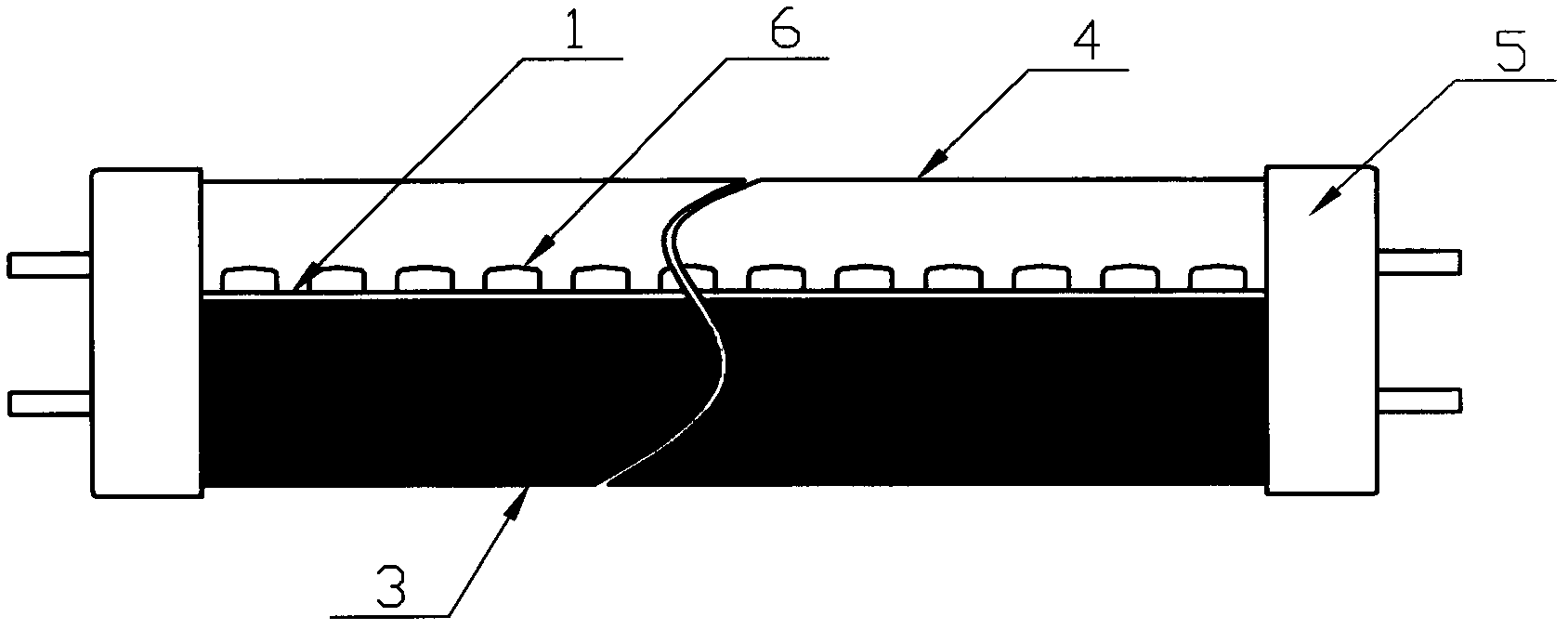

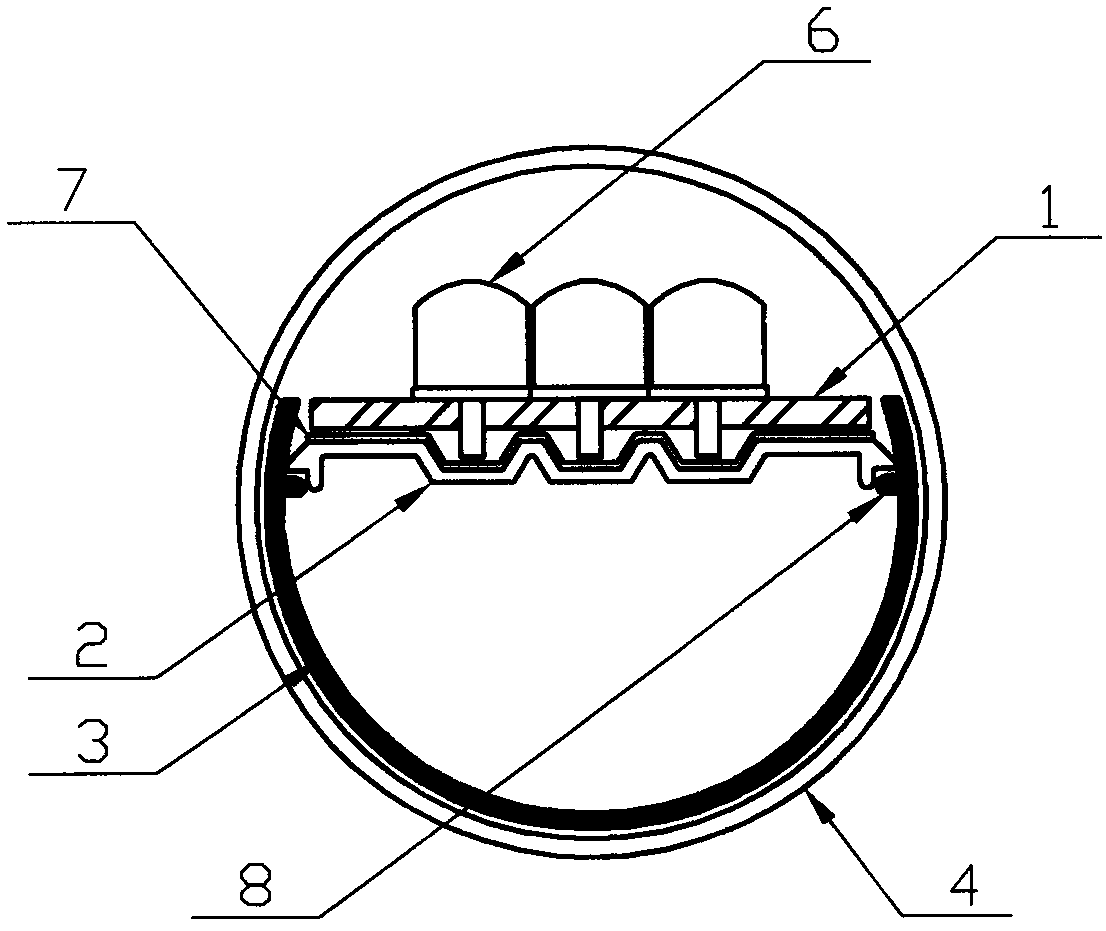

[0036] Such as figure 1 , figure 2 As shown, the present invention is composed of an LED lamp board 1, a lamp bead heat conducting plate 2, a metal heat dissipation inner sleeve 3, a lamp tube outer cover 4, and a plug 5. The lamp beads 6 are welded on the lamp board 1, and the metal heat dissipation inner sleeve 3 is an opening The two inner sides of the metal heat dissipation inner sleeve 3 are respectively provided with convex strips 8, the outer diameter of the arc of the metal heat dissipation inner sleeve 3 is the inner diameter of the lamp tube outer cover 4, and the LED lamp board 1 is connected with the heat-conducting silica gel 7. The lamp bead heat conduction plate 2 is fixedly connected and placed on the convex strip 8 provided by the metal heat dissipation inner sleeve 3. The two sides of the lamp bead heat conduction plate 2 are attached to the two inner sides of the metal heat dissipation inner sleeve 3 and placed together inside the lamp tube outer cover 4 C...

Embodiment 2

[0045] Such as Figure 10 , Figure 11As shown, it is composed of an LED lamp board 30, a lamp bead heat conducting sleeve 31, a lamp tube cover 32, a plug 33, and an LED constant current device 34. Bat-shaped, lamp bead heat conducting plate 35 is provided with more than one groove 37, the lamp bead pin 38 of LED lamp board 30 is placed in the groove 37, and put into the inner cavity of lamp tube outer cover 32 together, LED constant current The device 34 is placed in the hollow position where the lamp bead heat conduction sleeve 31 and the lamp tube cover 32 are combined. The outer diameter of the arc edge 36 on both sides of the bat-shaped lamp bead heat conduction sleeve 31 is slightly smaller than the inner diameter of the lamp tube cover 32, which is consistent with the lamp tube cover 32 inner walls are in contact with each other. The LED lamp board 30 is fixed on the lamp bead heat conduction sleeve 31 through heat conduction silica gel 39. In the middle of the lamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com