On-road impact vibration wireless real-time monitoring system of large electric power item

A technology of shock vibration and large power parts, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of endangering transportation safety, long transportation time, and not easy to carry, so as to avoid the expansion of faults and the external structure Simple, easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

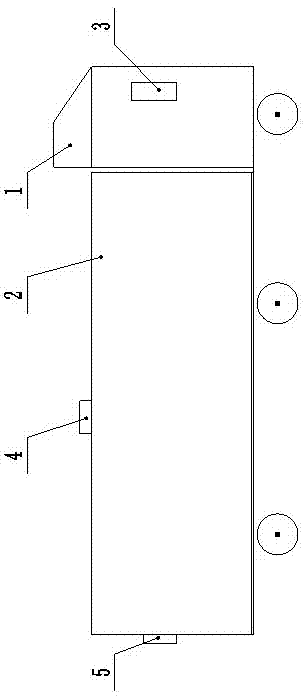

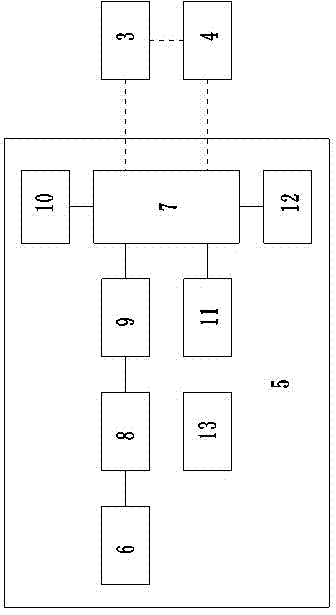

[0027] Such as figure 1 As shown, the shock vibration wireless real-time monitoring system for large electric parts in transit of the present invention includes a centralized controller 3 installed in the driver's cab of the large electric part transport vehicle 1, a router 4 installed on the top of the large electric part 2, and a The shock vibration wireless real-time monitoring device 5 at the front end or the rear end, the centralized controller 3, the router 4 and the shock vibration wireless real-time monitoring device 5 can all communicate through a wireless network.

[0028] Above-mentioned centralized controller 3 sends order to router 4 and shock vibration wireless real-time monitoring device 5, and stores the information sent by router 4 and shock vibration wireless real-time monitoring device 5; router 4 mainly plays the role of auxiliary information transmission, and the length of large power part 2 Generally all relatively long, adopting router 4 can increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com