Cable shielding layer processing structure of plug

A cable shielding layer and shielding layer technology, which is applied in the direction of connecting parts, such as protective grounding/shielding devices, can solve the problems of complicated operation, complicated handling of multiple shielding layers of scattered parts, and the shielding structure cannot be compatible with cables with a large diameter range. Simple operation, good retention force, and the effect of preventing screw loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

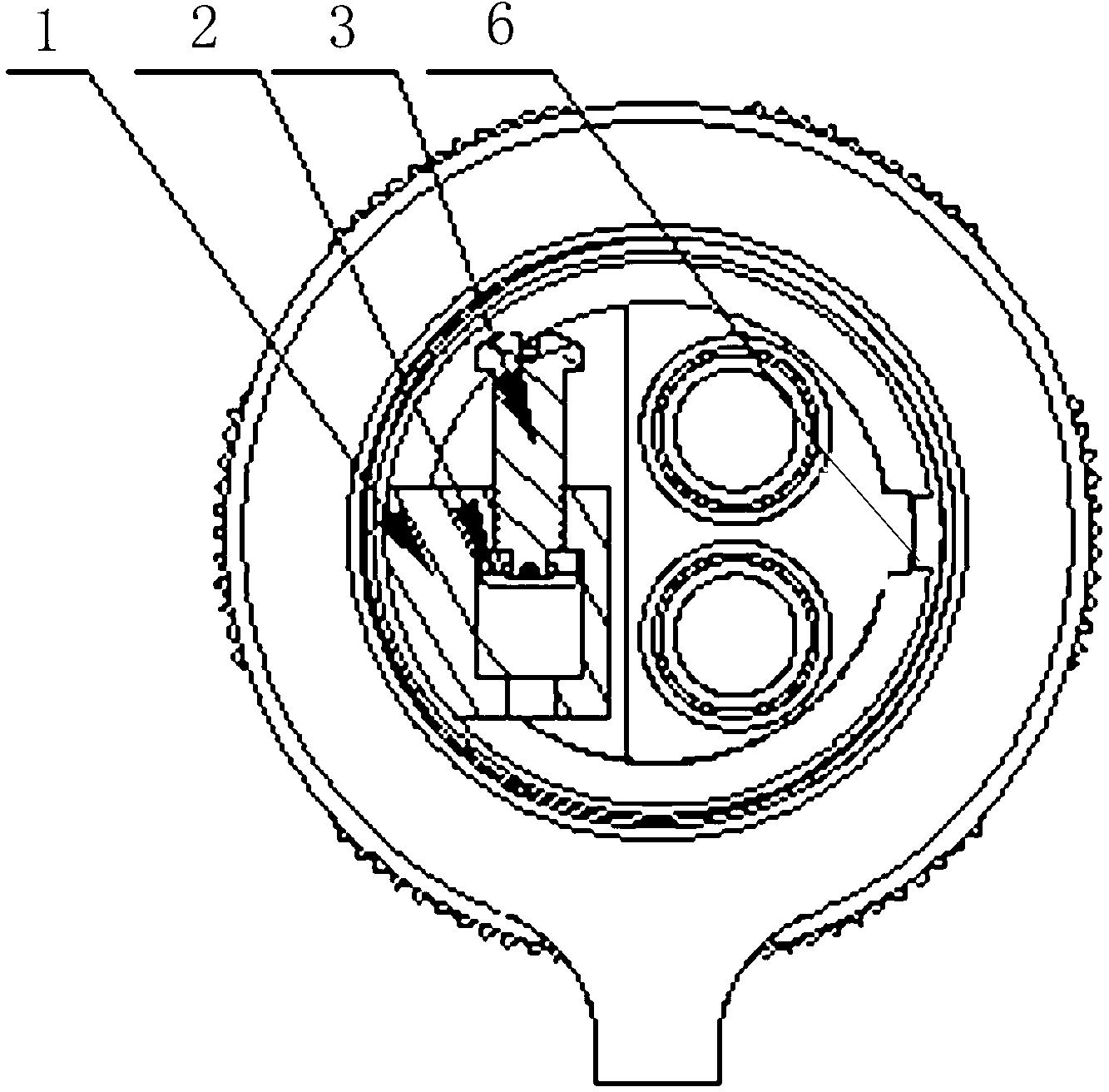

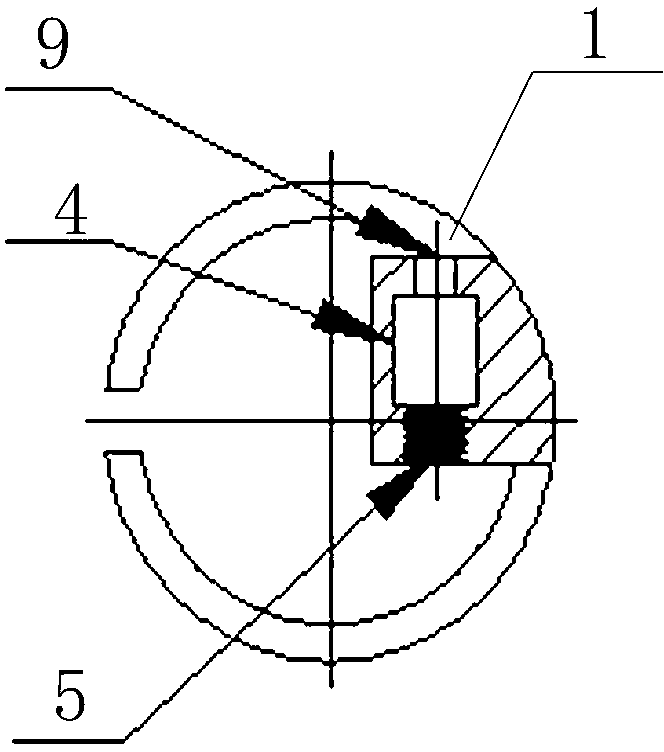

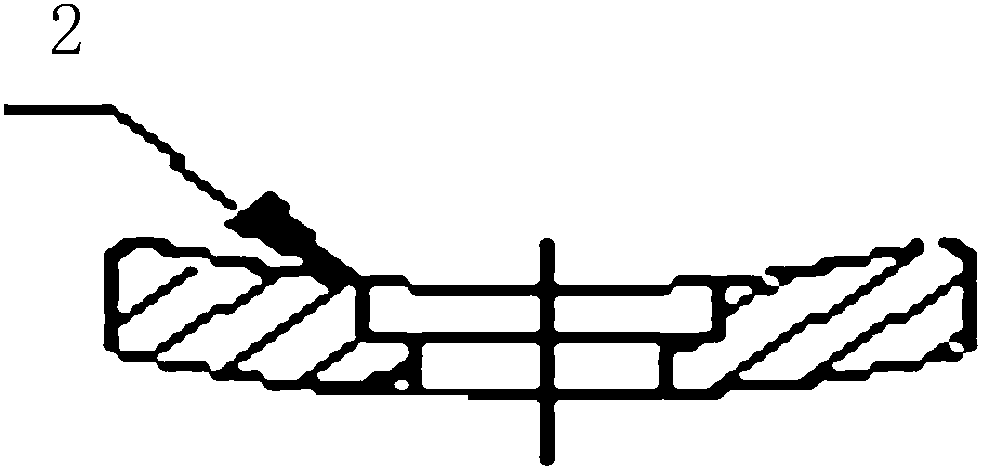

[0011] exist figure 1 , figure 2 , image 3 and Figure 4 In the present invention provides a cable shield handling structure for the plug that It includes a shielding sleeve 1, a shielding wire clamp 2 and a fastener 3, the shielding wire clamp 2 is set as an arc-shaped plate, and one side of the shielding sleeve 1 is provided with a shielding layer loading hole 4, The cable shield is set at The shielding layer is loaded into the hole 4, and the shielding layer loading hole 4 is set as a square hole. The square hole is convenient for the shielding wire to be clamped in the hole to move and lock the shielding layer. A fastener 3 is installed on the shielding layer loading hole 4. The shielding wire clamp 2 described above is set in the shielding layer loading hole 4, the fastener 3 corresponds to the shielding wire clamp 2, and the fastener 3 is connected by the shielding wire clamp 2 The cable shield is locked, The fastener 3 is set as a fastening screw, and one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com