Hydraulic chuck turning clamp of numerically controlled lathe

A technology of hydraulic chuck and CNC lathe, which is applied in the direction of clamping, manufacturing tools, supports, etc., which can solve the problems of unguaranteed turning quality, easy deformation of the clamping surface of soft jaws, and affecting the processing quality of workpieces, etc. Low cost, small degree of deformation, and the effect of ensuring turning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below with reference to the drawings.

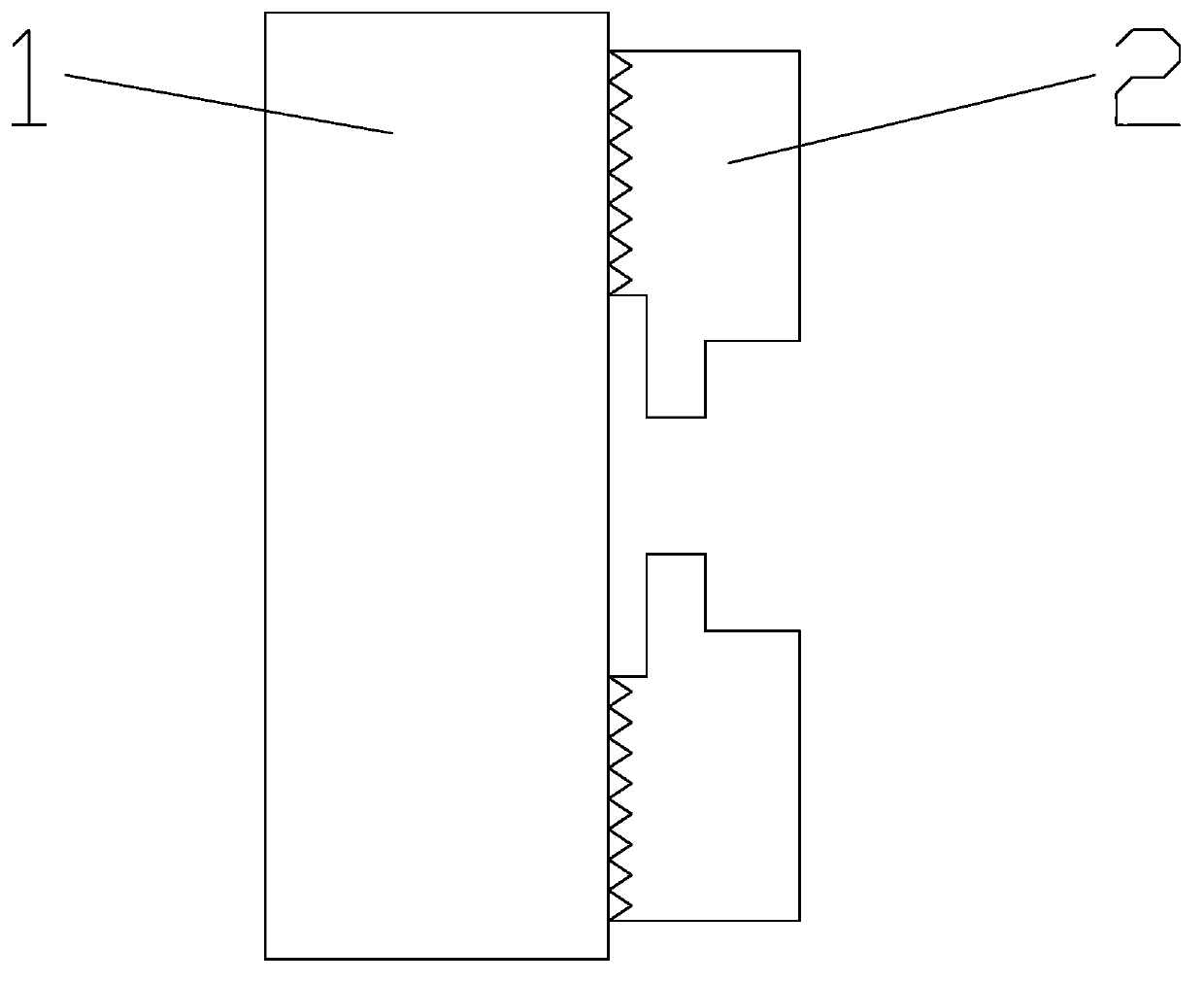

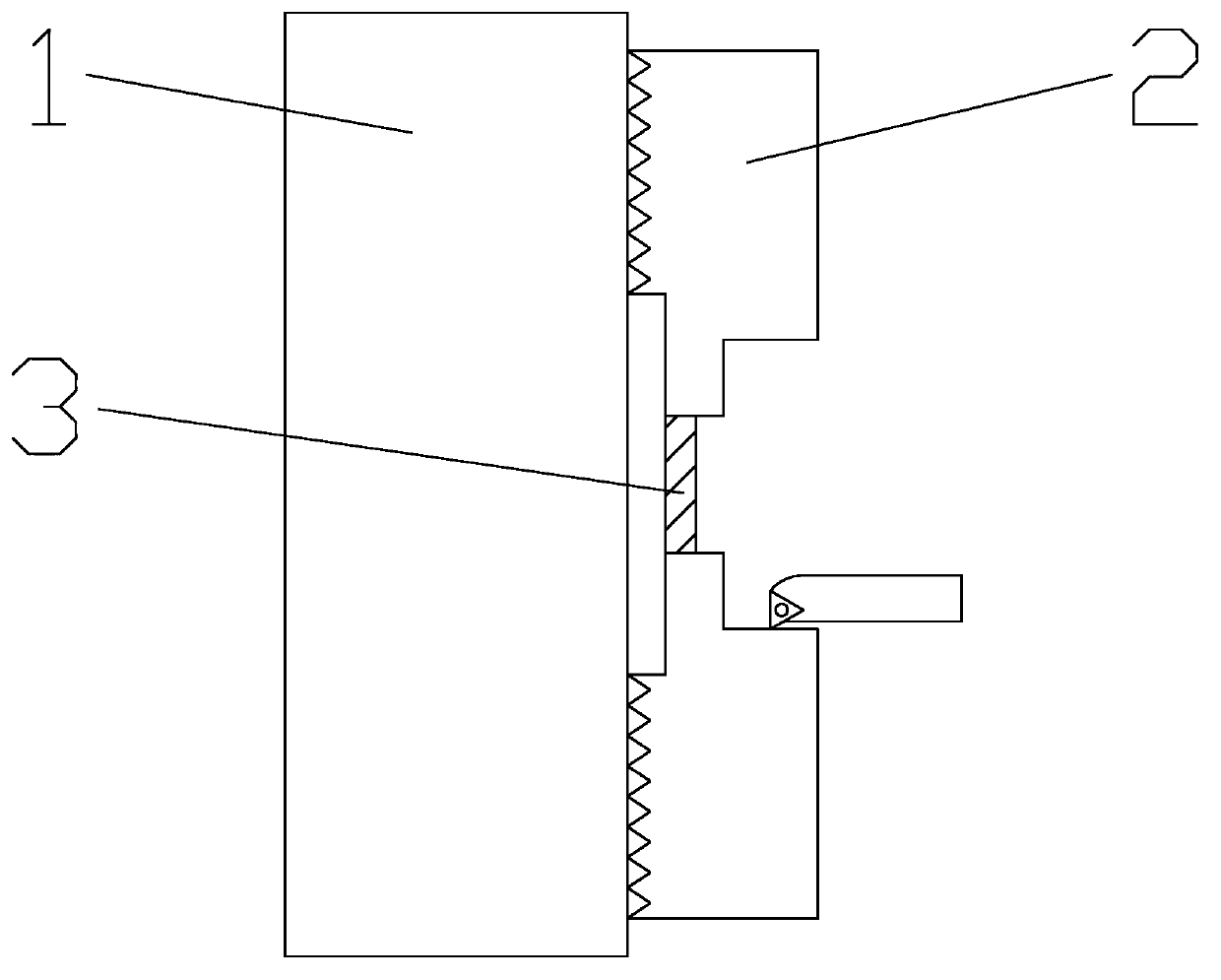

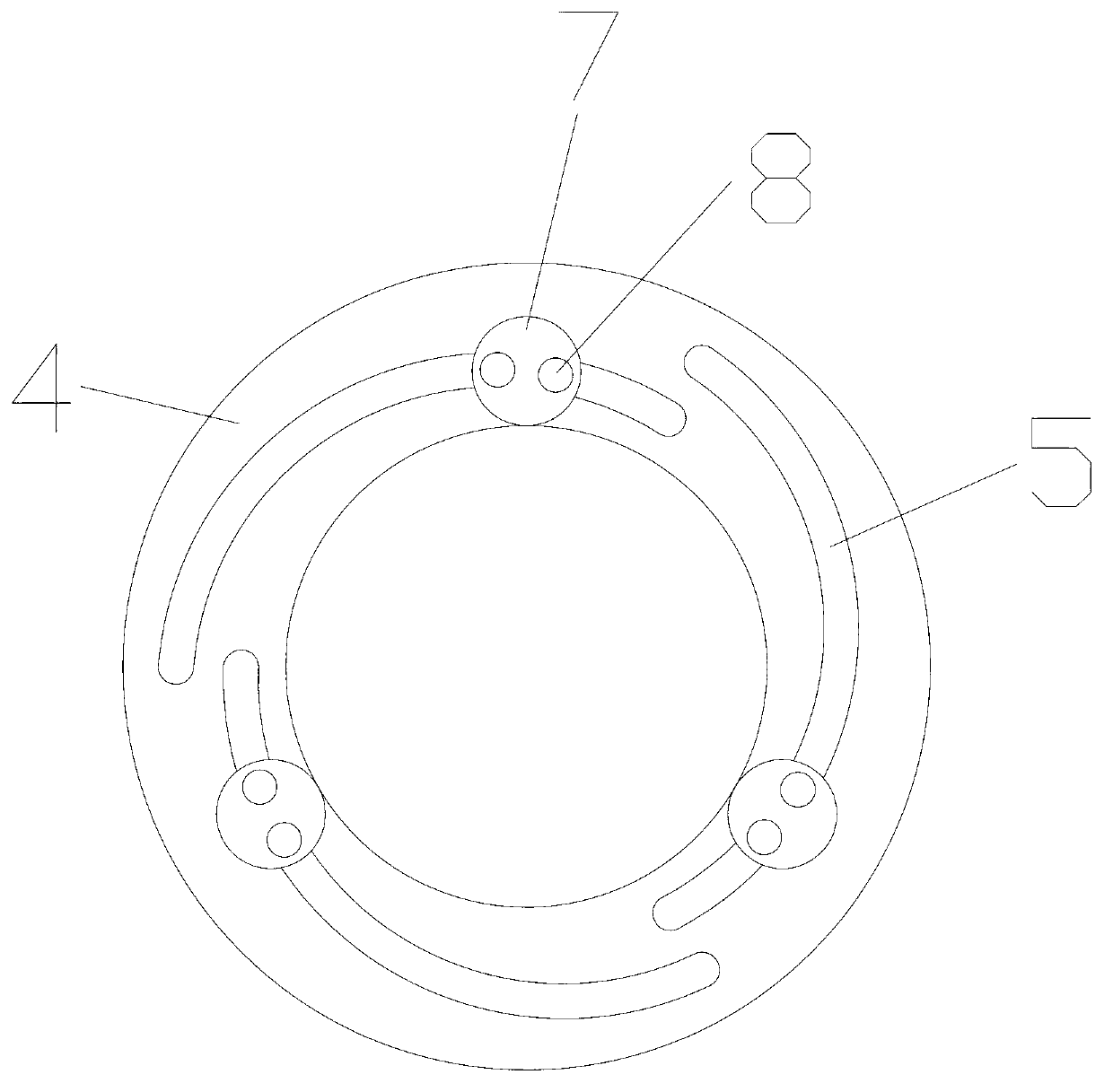

[0017] As attached image 3 , 4 The hydraulic chuck turning fixture of a numerical control lathe according to the present invention shown in the present invention includes a circular ring clamp body 4; the circular ring clamp body 4 is provided with three identical non-concentric arc grooves 5; Each arc groove 5 is provided with a fixing pin 6 that can slide in the arc groove; the outer end of the fixing pin 6 is fixed with a stopper 7 by a fastener; the fastener 8 is a screw.

[0018] As attached Figure 5 The hydraulic chuck turning fixture of a numerical control lathe according to the present invention is shown. When in use, three fixing pins 6 are respectively inserted into the screw counterbores 9 of the soft jaw 2. When the soft jaw 2 is closed, the three fixed The pin 6 can be automatically adjusted to the best position to clamp the soft jaw 2 and then turn the clamping surface of the sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com