Big-bag powder packaging machine

A packaging machine and big bag technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of inconvenient use, inaccurate loading control, slow speed, etc., and achieve reliable performance, easy operation and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

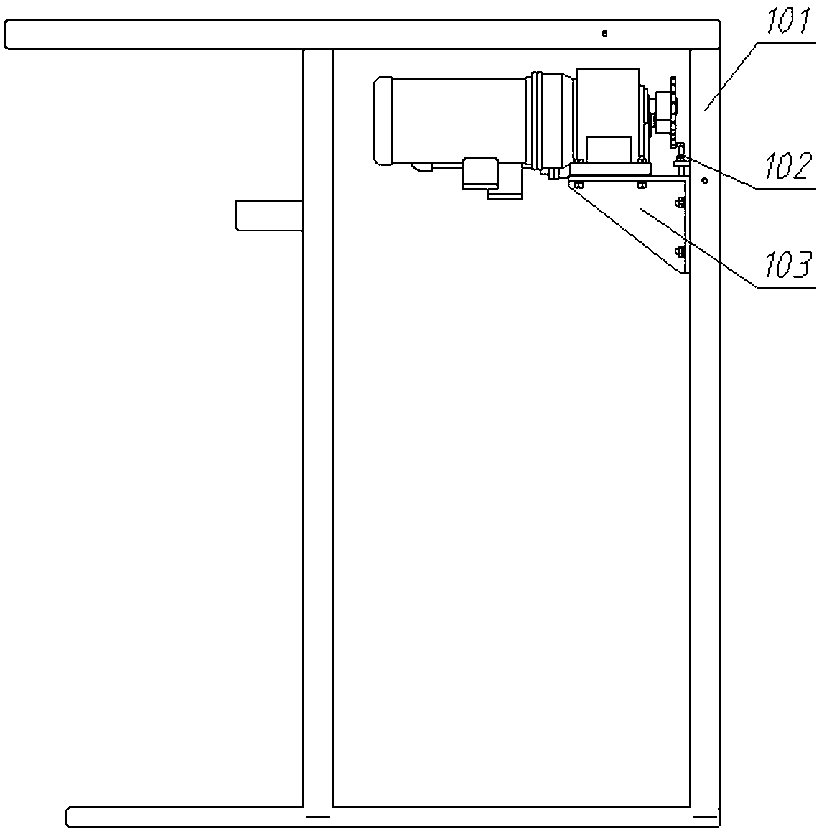

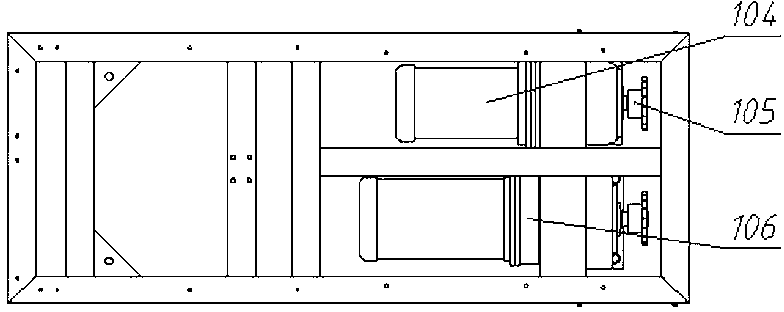

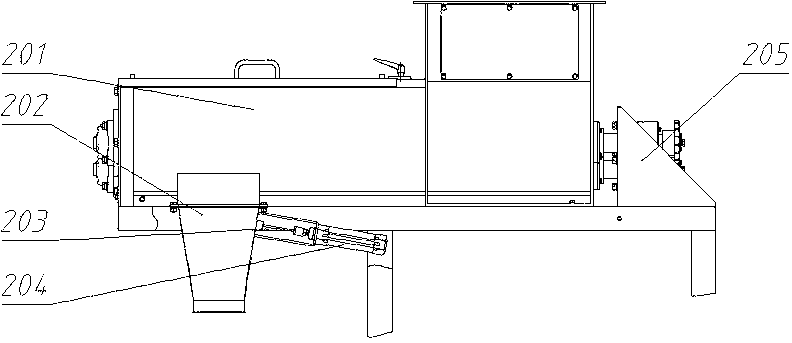

[0019] See attached Figure 1~6 , a kind of powder big bag packing machine of the present invention, comprises frame part 100, and described frame part 100 is installed with feeding part and bag holder part 300, is characterized in that: described feeding part is configured by respectively The screw feeding part 200 formed by the large screw 210 used for fast feeding and the small screw 208 used to control the feeding amount of the feeding drive device, the screw feeding part 200 includes a screw housing 201, and the screw housing The body 201 is equipped with a small screw end plate 206, a large screw end plate 209, a shaft seat mounting plate 205 and a lower hopper 202. A cylinder 204 is installed on the lower hopper 202, and a gate 203 is installed on the telescopic rod of the cylinder 204. , the two ends of the small screw 208 and the large screw 210 are respectively installed with seat bearings 207 and shaft seats 211, and the two seat bearings 207 are respectively instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com