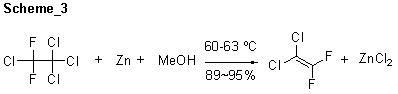

1-chloro-2,2-difluoroethylene preparation method

A technology of difluoroethylene and R122, which is applied in the field of preparation of 1-chloro-2,2-difluoroethylene, can solve the problems of large amount of reaction solvent, expensive raw materials, poor reaction selectivity, etc., and achieves low cost and low raw material cost. Low, mild response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1 Zinc powder pretreatment

[0053] Stir 1.2kg of zinc powder with 3 L 2% hydrochloric acid for 1 hour, filter to remove the acid, put the zinc powder in a 5 L beaker, wash once with 3 L 2% hydrochloric acid, and then wash three times with distilled water (each time 3 L), then washed twice with 95% ethanol (2 L each time), and finally washed once with 2 L of anhydrous ether. Filter after each wash to remove the wash solution. The treated zinc powder is thoroughly dried under the protection of nitrogen, and the lumps are ground in a mortar. After the treatment, the zinc powder was obtained under the protection of nitrogen for standby use.

[0054]

Embodiment 2

[0056] A two-stage reflux condenser is connected to a 5-liter there-necked bottle equipped with a mechanical stirrer and a constant-pressure dropping funnel, wherein the first-stage reflux condenser is cooled by tap water, and the second-stage reflux condenser is condensed by circulating alcohol in a refrigerator. Control the temperature of the alcohol at -10~-20°C, the generated product is exported through the reflux condenser, and the product is collected into a steel cylinder by circulating anhydrous alcohol in a refrigerator, and the temperature of the absolute alcohol is controlled at -50~-60°C. The reaction bottle was heated by an oil bath, and the reaction temperature was controlled by an electronic temperature controller.

[0057] Replace the above device with nitrogen, add 1 liter of sulfolane (industrial product, Liaoyang Guanghua Chemical Co., Ltd.), 113 grams of activated zinc powder (analytical pure, Shanghai Shenxiang Chemical Reagent Co., Ltd.) Sodium sulfite, r...

Embodiment 3

[0062] A two-stage reflux condenser is connected to a 5-liter there-necked bottle equipped with a mechanical stirrer and a constant-pressure dropping funnel, wherein the first-stage reflux condenser is cooled by tap water, and the second-stage reflux condenser is condensed by circulating alcohol in a refrigerator. Control the temperature of the alcohol at -10~-20°C, the generated product is exported through the reflux condenser, and the product is collected into a steel cylinder by circulating anhydrous alcohol in a refrigerator, and the temperature of the absolute alcohol is controlled at -50~-60°C. The reaction bottle was heated by an oil bath, and the reaction temperature was controlled by an electronic temperature controller.

[0063] Replace the above device with nitrogen, add 2 liters of 1,4-dioxane (China Wulian Chemical Factory), 325 grams of activated zinc powder (analytical grade, Shanghai Shenxiang Chemical Reagent Co., Ltd.) and 15 grams of sodium dithionite was re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap