Control method for wind power generator

A technology of a wind turbine and a control method, applied in the control field, can solve the problems of high winding temperature, excessive wind speed, unstable wind direction, etc., and achieve the effect of improving work stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

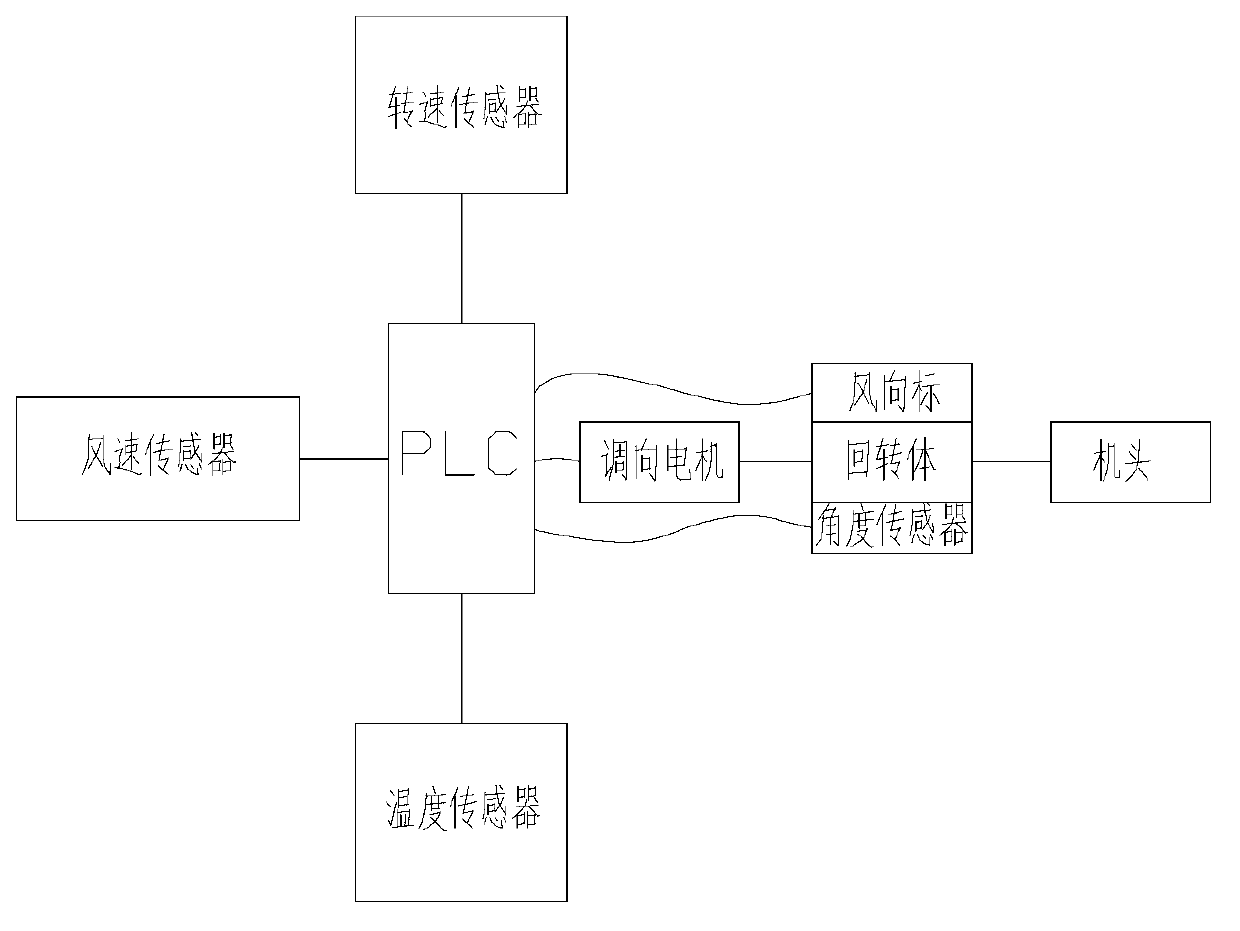

[0014] Such as figure 1 shown. A wind-driven generator control method, the wind-driven generator includes a machine head, a generator installed in the machine head, a blade mounted on one end of the machine head to rotate, a rotator for the machine head to be installed and to drive the machine head to move, and a rotor to control the movement of the rotator The direction-adjusting motor, in which the central shaft of the blade is connected to the generator rotor, a wind speed sensor is installed on the wind generator, a wind vane and an angle sensor are installed on the rotor, a speed sensor is installed near the generator rotor, and a wind speed sensor is installed on the generator winding A temperature sensor is installed on the top, and the wind speed sensor signal output terminal, wind vane signal output terminal, angle sensor signal output terminal, speed sensor signal output terminal, temperature sensor signal output terminal, and steering motor control terminal are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com