A system and process for producing alternative natural gas

A technology to replace natural gas and products, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of difficulty in eliminating stress, difficult to withstand high pressure, large pressure drop in the reactor, shortening processing time, reducing equipment investment, and reaction efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

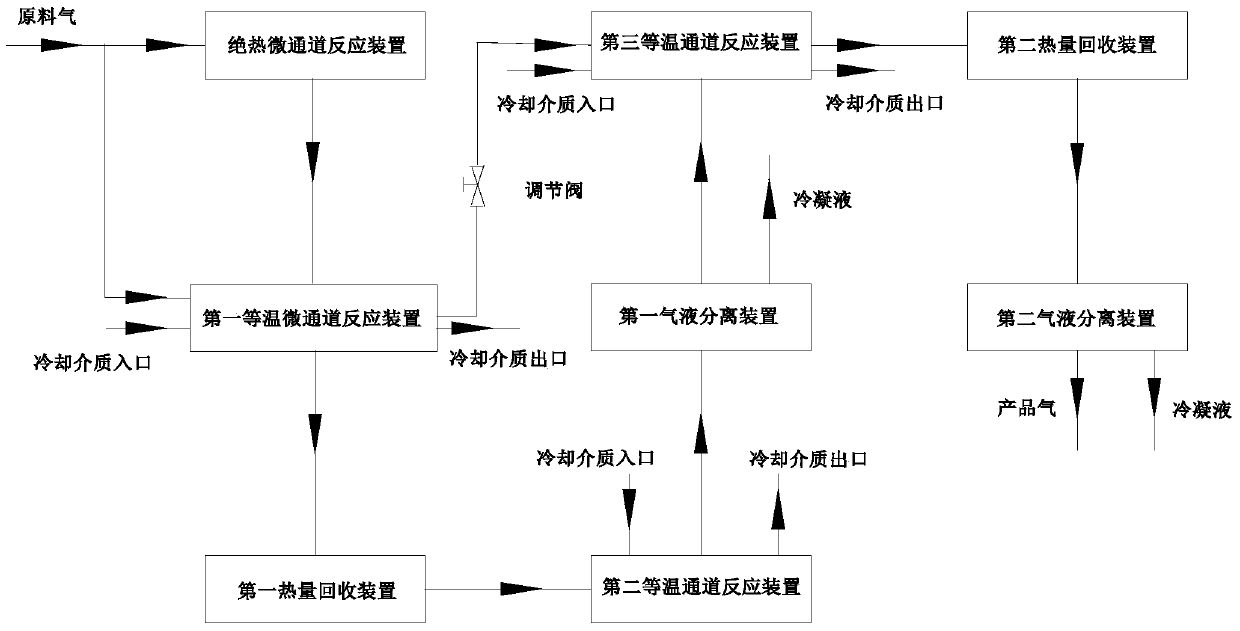

[0080] In this embodiment, the adiabatic microchannel reaction device, the first isothermal microchannel reaction device, the second isothermal microchannel reaction device and the third isothermal microchannel reaction device are respectively provided with a microchannel reactor, and the first isothermal microchannel reaction device is closed. A regulating valve between the channel reaction device and the third isothermal microchannel reaction device.

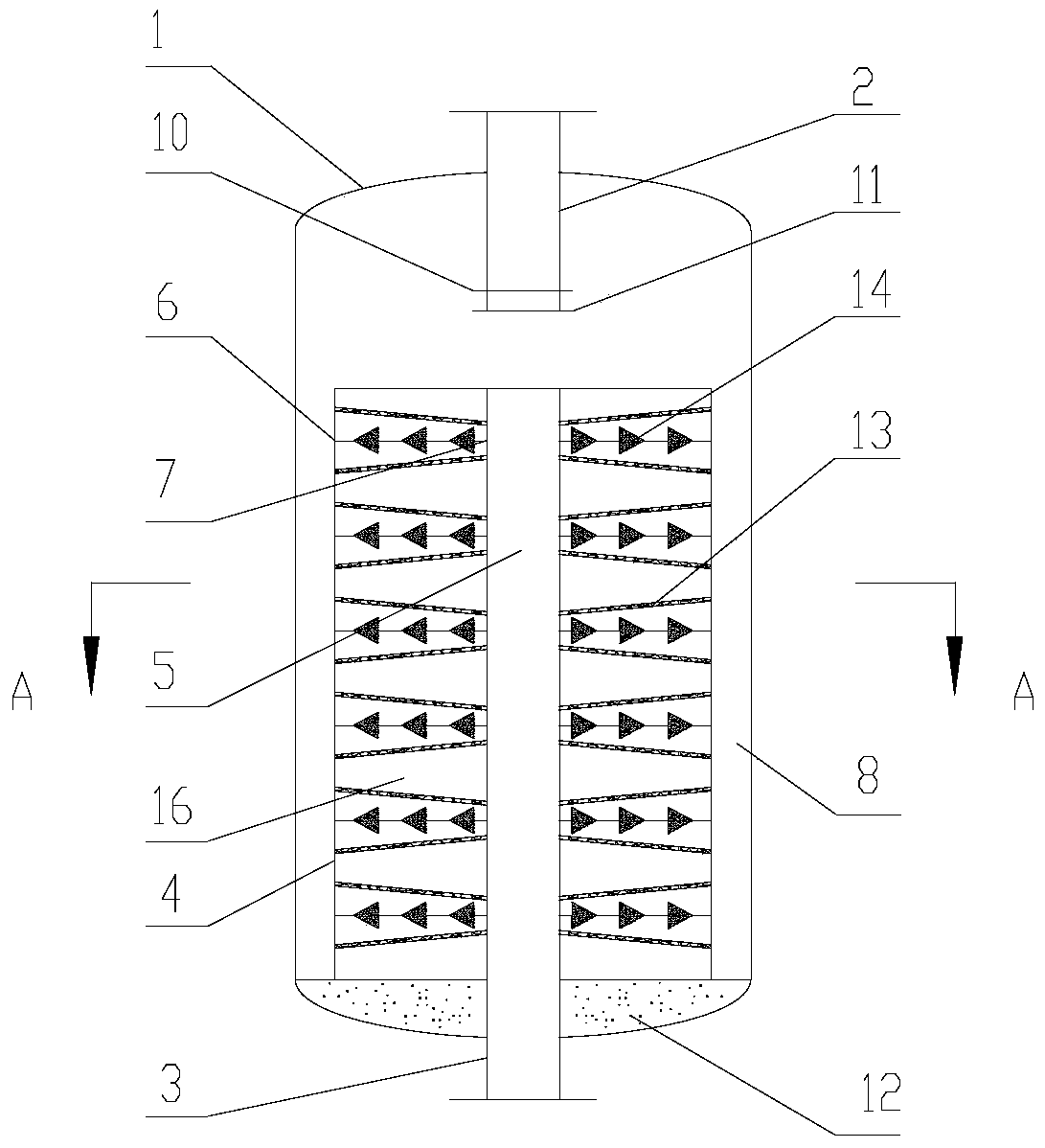

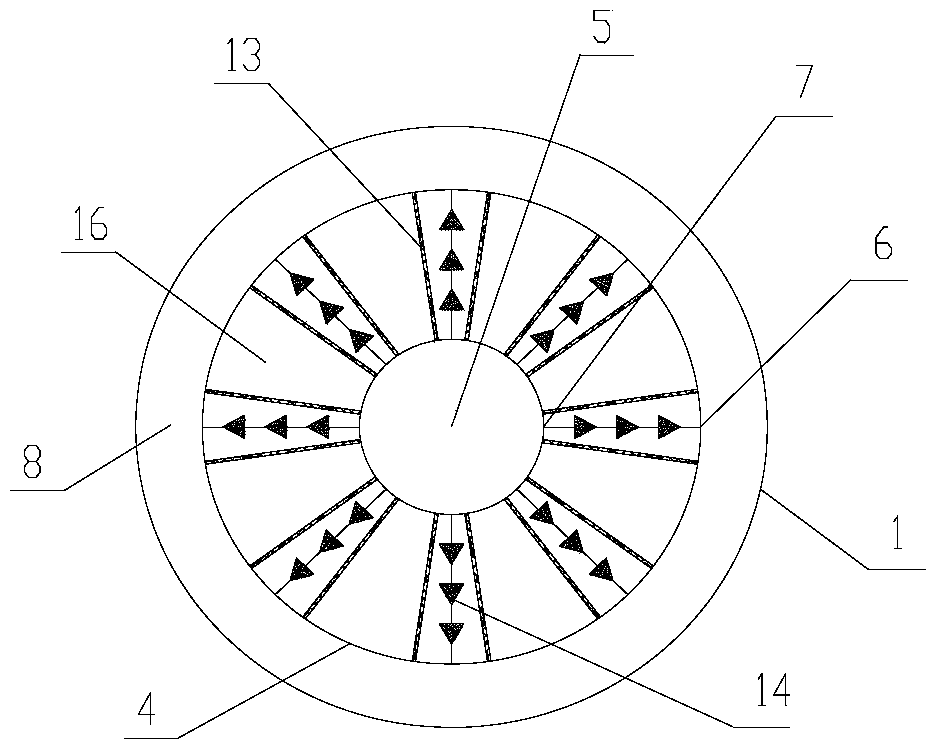

[0081] The microchannel reactor that the adiabatic microchannel reaction device adopts in the present embodiment is as figure 2As shown, it includes a radial cylindrical sealed pressure-bearing shell 1, an air inlet pipe 2 extending from the top of the shell 1 into the inside of the shell, an air outlet pipe 3 and a radial catalytic reaction zone. A first gas distributor 10 is provided at the lower part of the intake pipe 2 , and a second gas distributor 11 is provided below the first gas distributor 10 . Between the radial ...

Embodiment 2

[0089] The technological process that the present embodiment adopts is identical with embodiment 1, and difference is to open the regulating valve between the first isothermal microchannel reaction device and the 3rd isothermal microchannel reaction device, so that part of the reaction material directly flows from the first isothermal microchannel reaction device. The reaction device enters the third isothermal microchannel reaction device.

[0090] The difference between the microchannel reactor adopted by the adiabatic microchannel reaction device in this embodiment and the reactor of embodiment 1 is that, in this embodiment, two sleeves are arranged outside the central cylinder, such as Figure 6 , Figure 7 As shown, a flow collector is formed between the two sleeves and between the inner sleeve and the central cylinder, and the number of tapered tube radial micro-reaction channels 13 in the entire radial catalytic reaction zone is 63,000 (for clarity, not all shown). Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com