Three-lip sealed bearing with protective ring

A technology of sealing bearings and retaining rings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as wear and affect the sealing and dustproof effect, and achieve the effects of improving the life of the seal, improving the seal, and strengthening the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

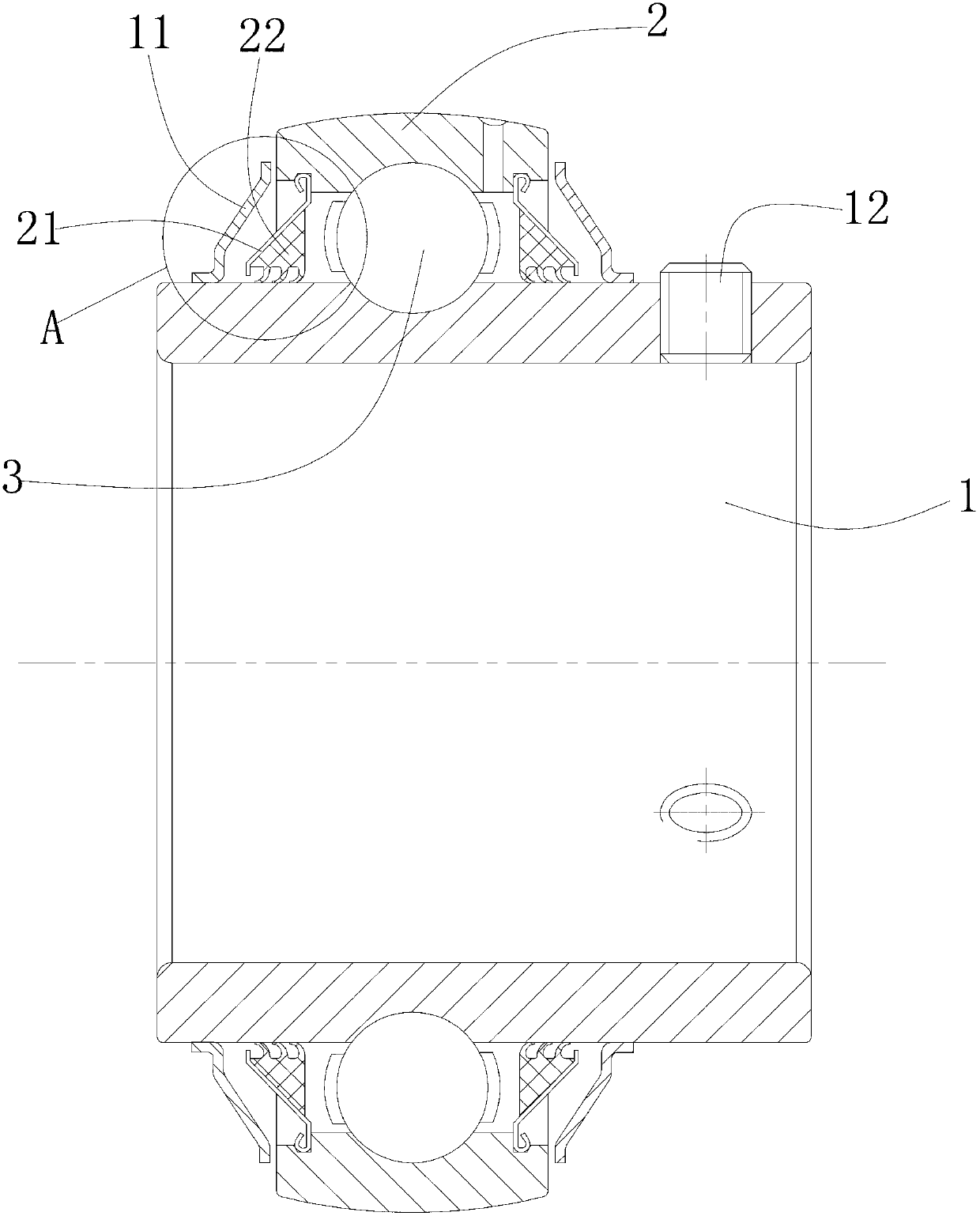

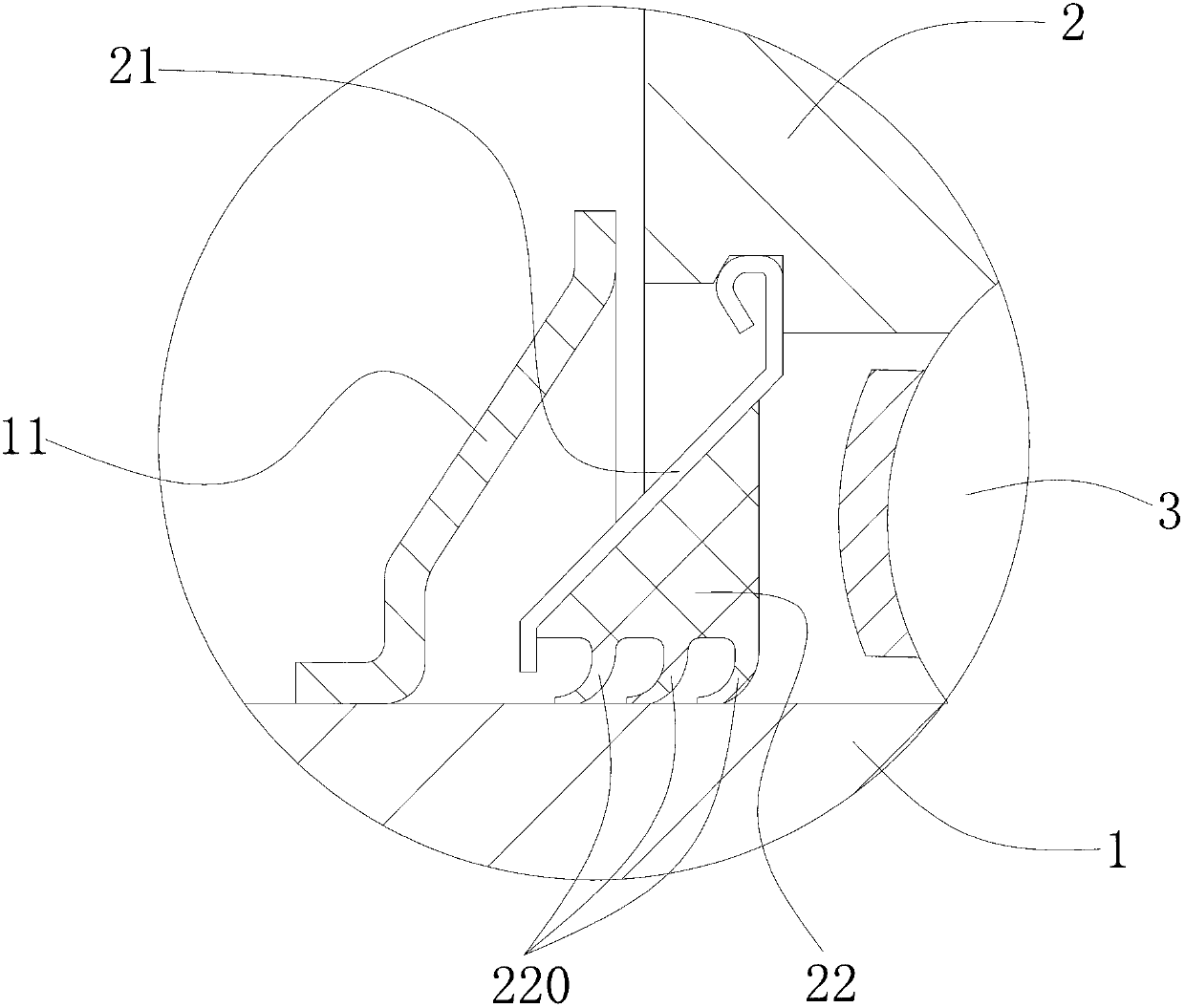

[0014] Such as figure 1 , 2 As shown, a three-lip sealed bearing with a protective retaining ring, the bearing includes an inner ring 1, an outer ring 2, a ball 3 arranged between the inner ring and the outer ring, and a retainer for making the balls circumferentially spaced The inner ring 1 protrudes from the left and right sides of the outer ring 2 in the axial direction, and the inner surfaces of the outer ring 2 are respectively provided with riveting grooves on the left and right sides of the axial direction, and a dustproof cover 21 is fixed in the riveting grooves , the dust cover 21 is provided with a three-lip seal 22 that seals against the outer surface of the inner ring 1, and the outer surface of the inner ring 1 is respectively fixed with the dust-proof seals at positions close to the left and right sides of the outer ring 2 The protective retaining ring 11 opposite to the cover 21, there is a small gap between the protective retaining ring 11 and the left or rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com