Simple oil and gas pipeline traction test method and device

A technology for oil and gas pipelines and testing methods, applied in the field of pipeline systems, can solve the problems of large overall floor space, high investment costs, and high traction test costs, and achieves the guarantee of accuracy and effectiveness, wide application prospects, and saving test space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

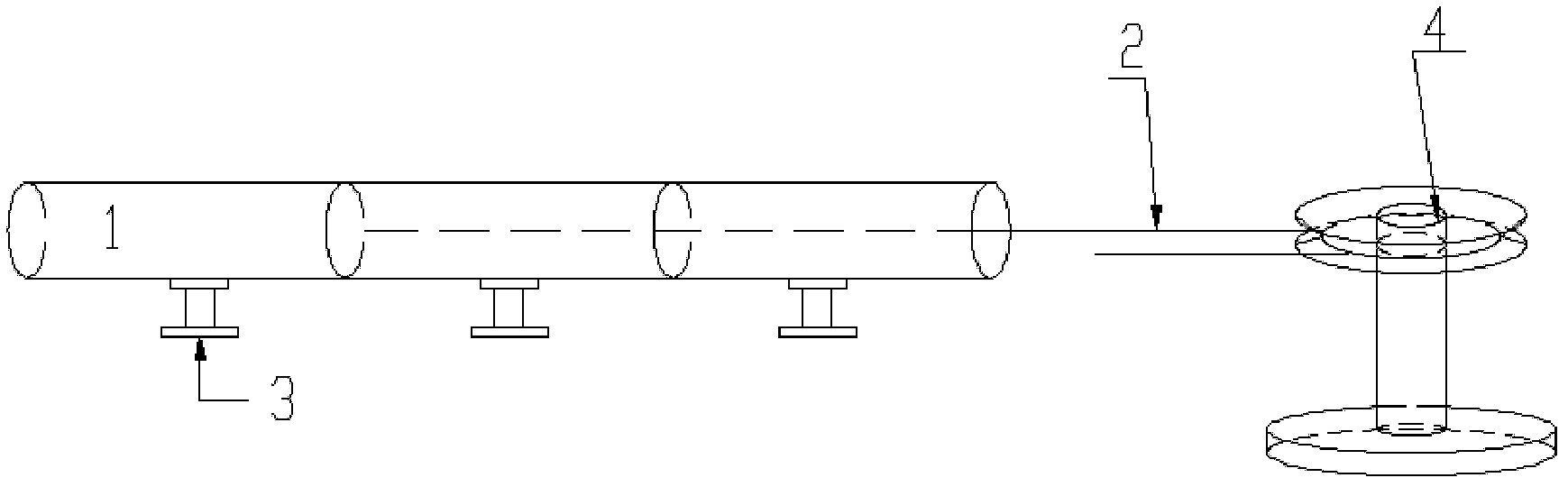

[0024] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is a test system prototype, its composition is as follows figure 1 shown.

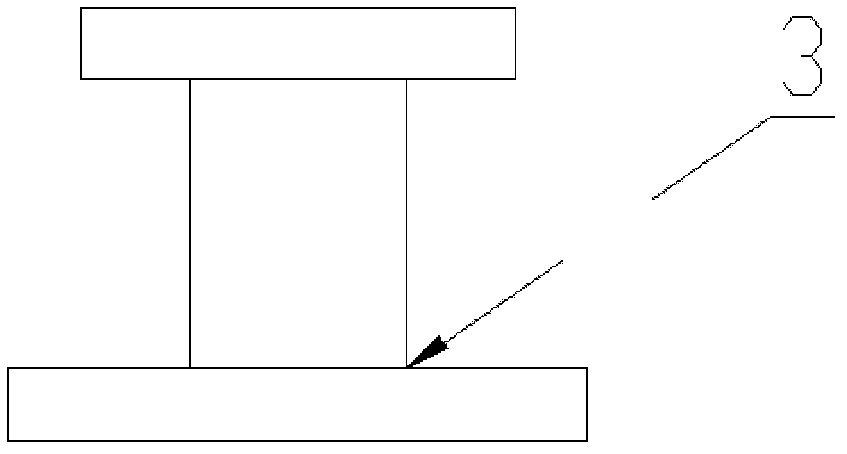

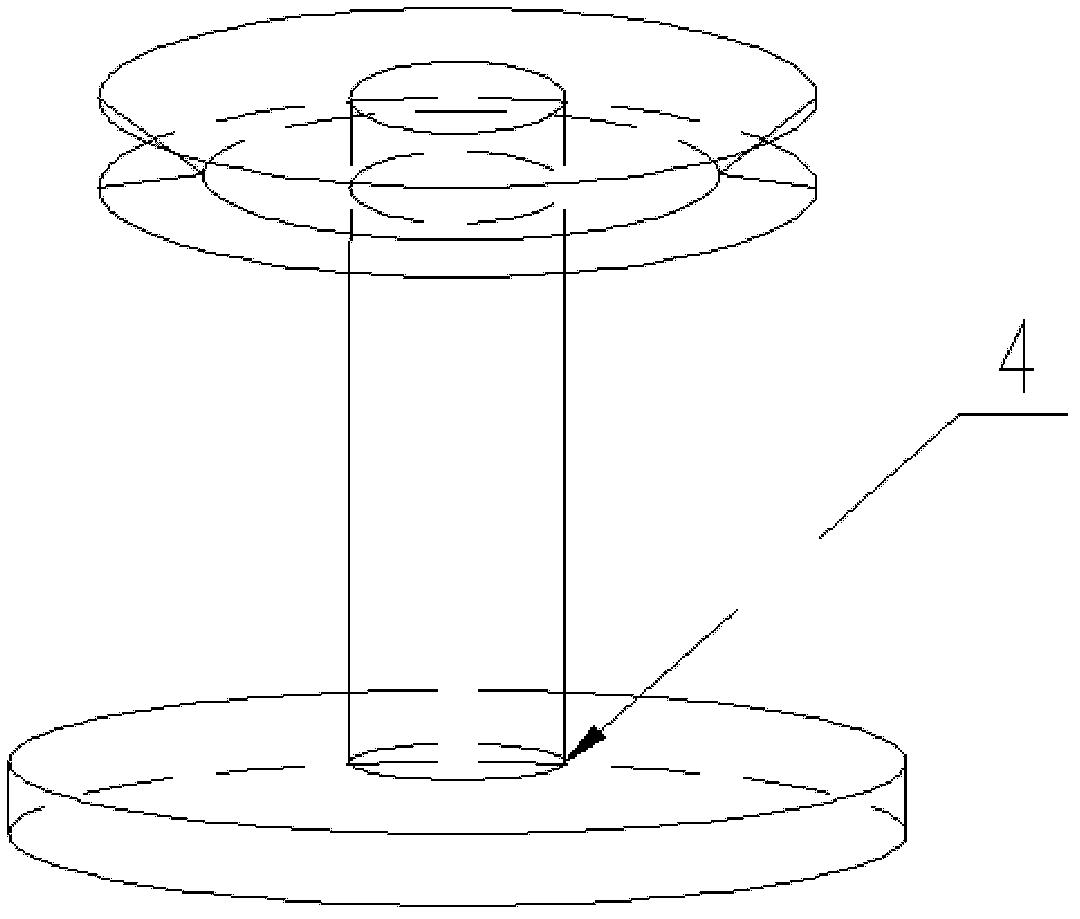

[0025] The traction test device is mainly composed of five parts: test pipeline support frame 3, power locomotive, guiding system, main traction rope 2 and auxiliary steel wire rope, fixed steering pulley 4 and its fixing device.

[0026] Place the defective pipeline 1 to be tested on the support frame 3, one end of the main traction rope 2 passes through the testing pipeline 1 for connecting the detector, and the other end passes through the steering fixed pulley 4 fixed on the ground for connecting the power locomotive; The auxiliary wire rope is used to pull the main traction rope 2 through the test pipeline 1 and pull it back to the initial traction position after completing a traction test to prepare for the next traction test.

[0027] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com