Method and device for oil and gas pipeline deformation detection verification test

A detection device and verification test technology, which is applied in the field of pipeline systems, can solve the problems of pipe body deformation detection and the determination of deformation detection performance indicators are not ideal, so as to ensure accuracy and effectiveness, improve accuracy, and have wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

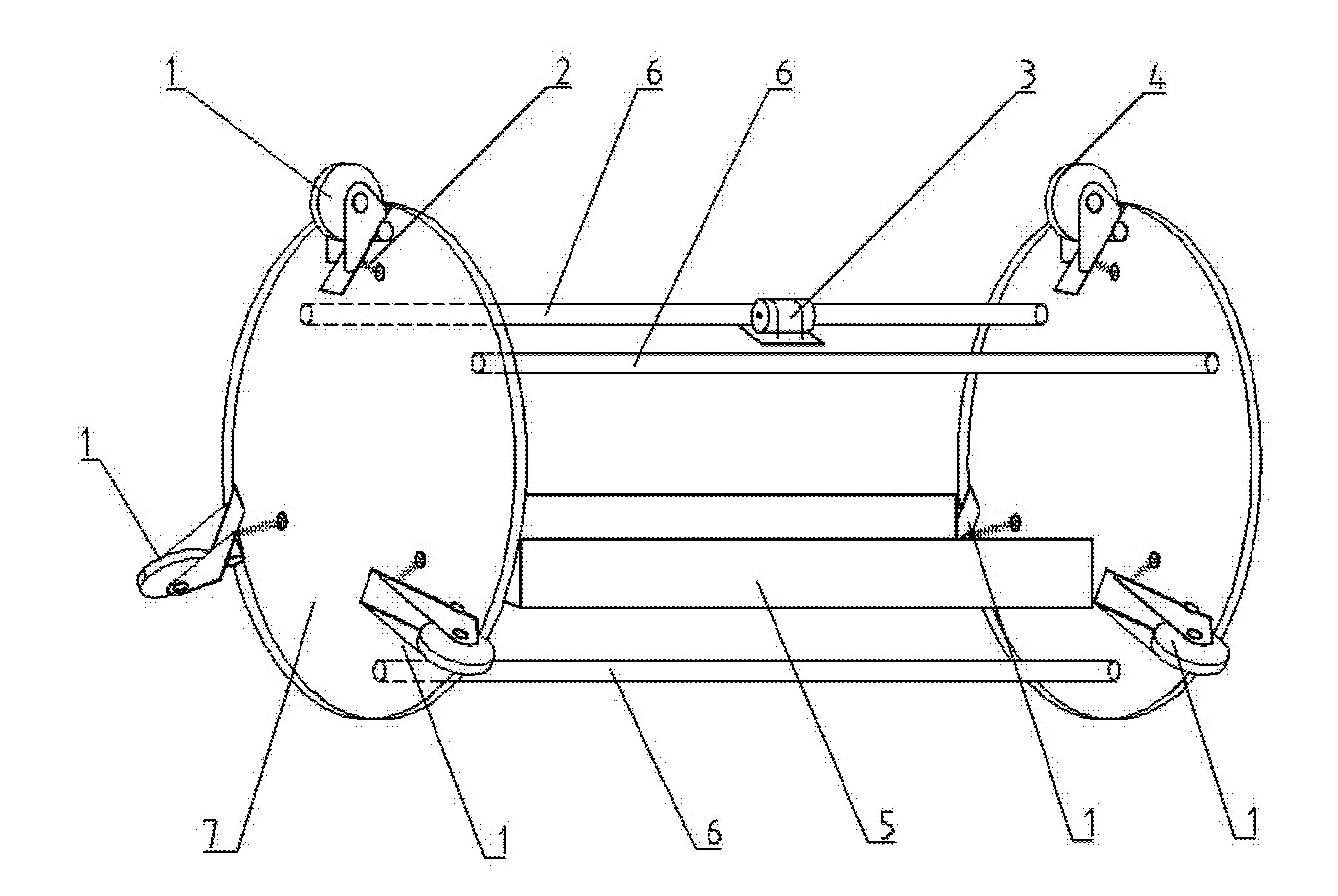

[0023] Embodiment. The specific embodiment of the present invention is described with this example and the present invention is described further. This example is a test system prototype, and its composition is shown in the figure.

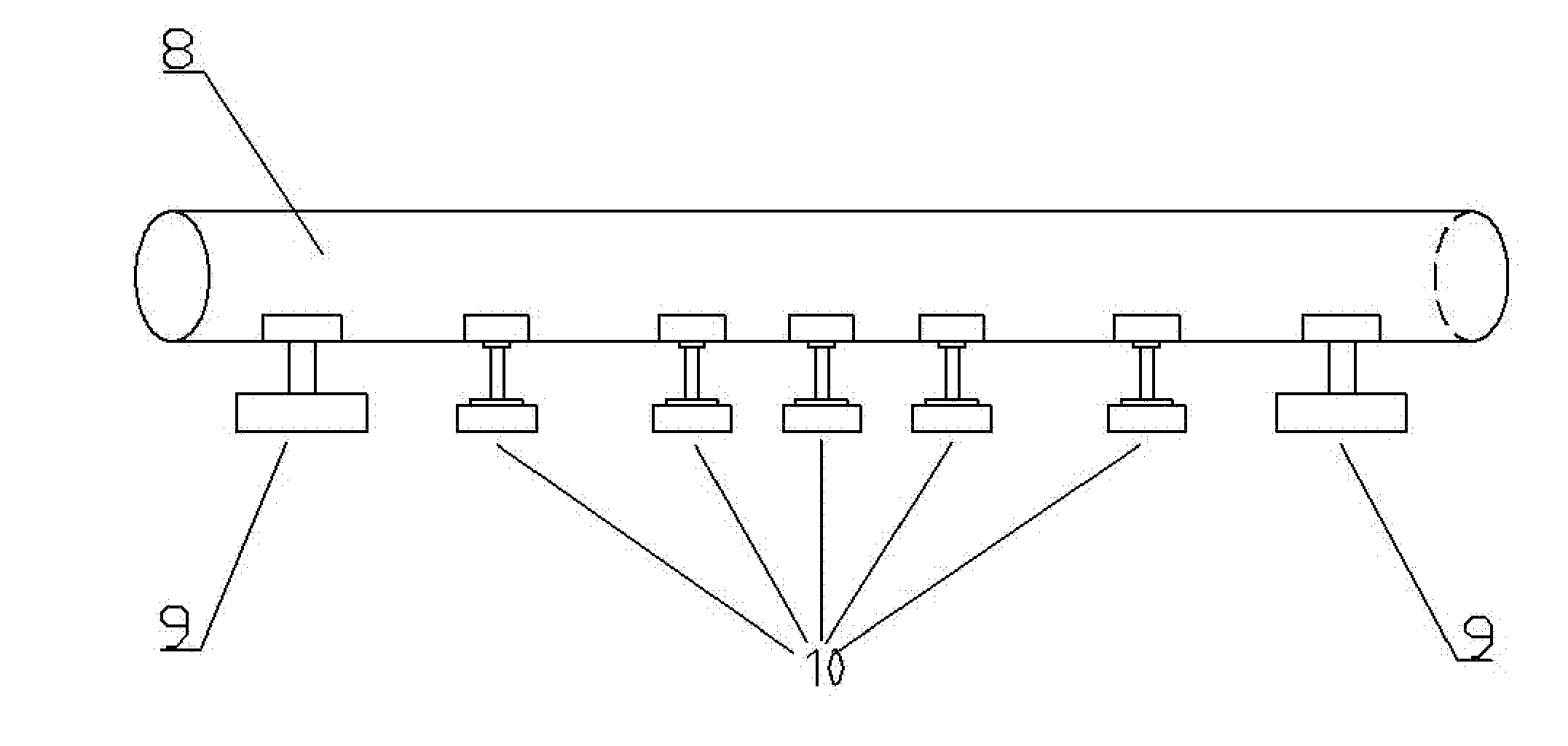

[0024] The pipeline deformation detection and verification test device consists of a support wheel 1, an odometer 3, a mileage wheel 4, a pipeline inertial measurement device tray 5, a fixed frame 6, a fixed plate 7, a pipeline to be tested 8, a fixed pier 9, and a jack device 10. Both ends of the pipeline 8 to be tested are supported by two fixed piers 9, and a plurality of jack devices 10 are placed between the two fixed piers 9 to contact the lower side of the pipeline 8 to be tested. Two fixed discs 7 are connected by three fixed frames 6 into an axial shape, and three support wheels 1 are installed on the same direction of the two fixed discs 7, one of which is replaced by mileage wheel 4, and the 6 support wheels 1 and mileage wheel 4 All h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com