Non-drain differential signal transmission cable and ground connection structure thereof

A differential signal and grounding structure technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as installation density restrictions, and achieve the effect of increasing installation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

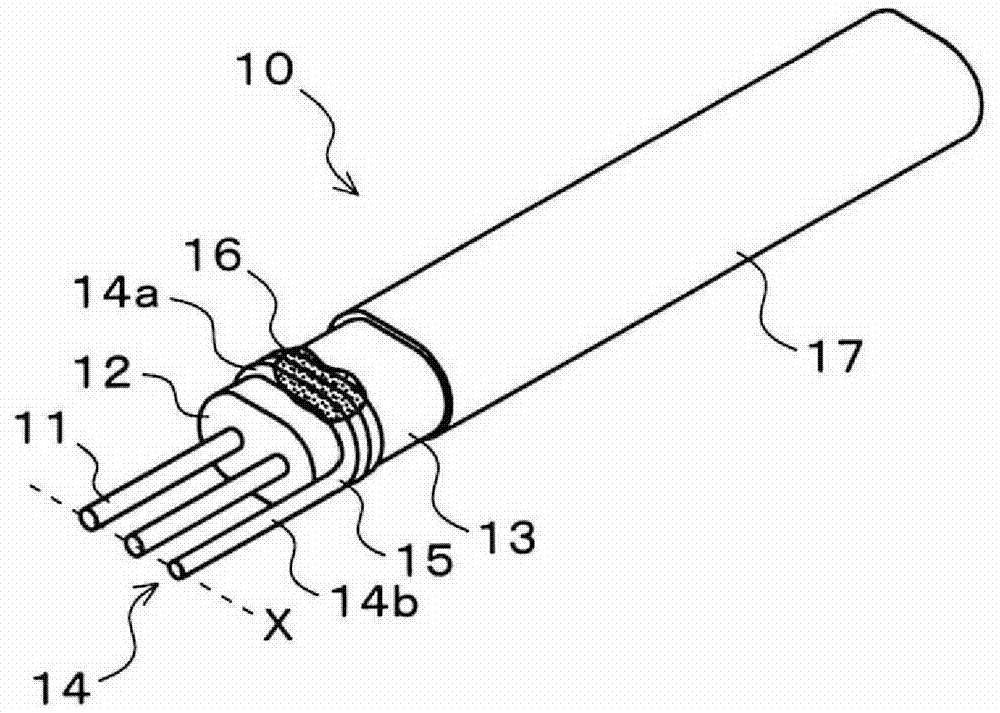

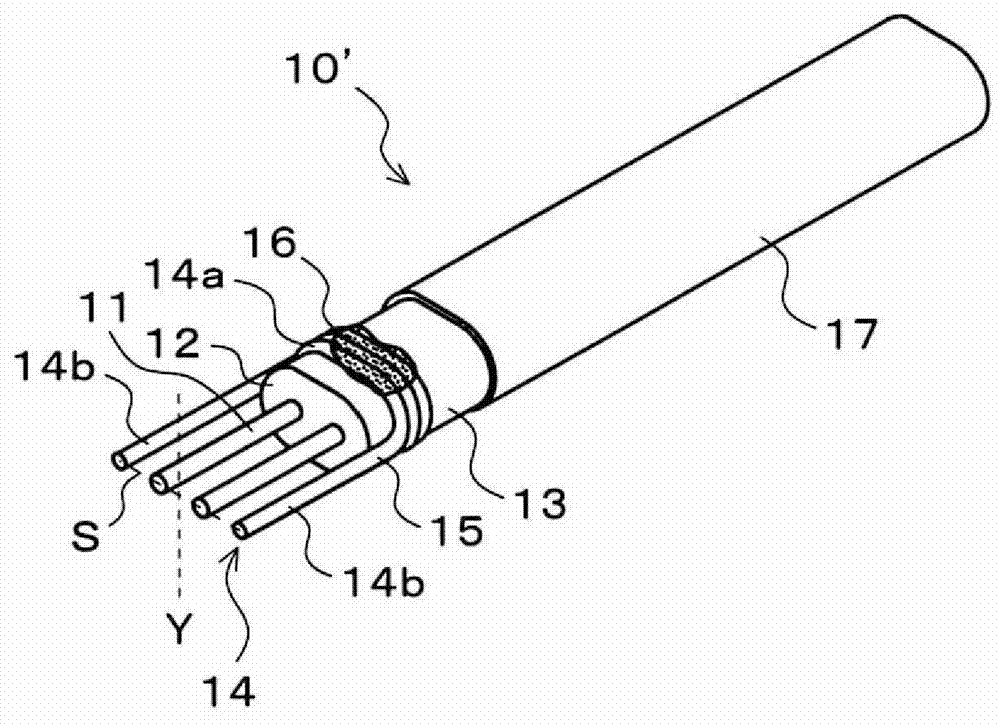

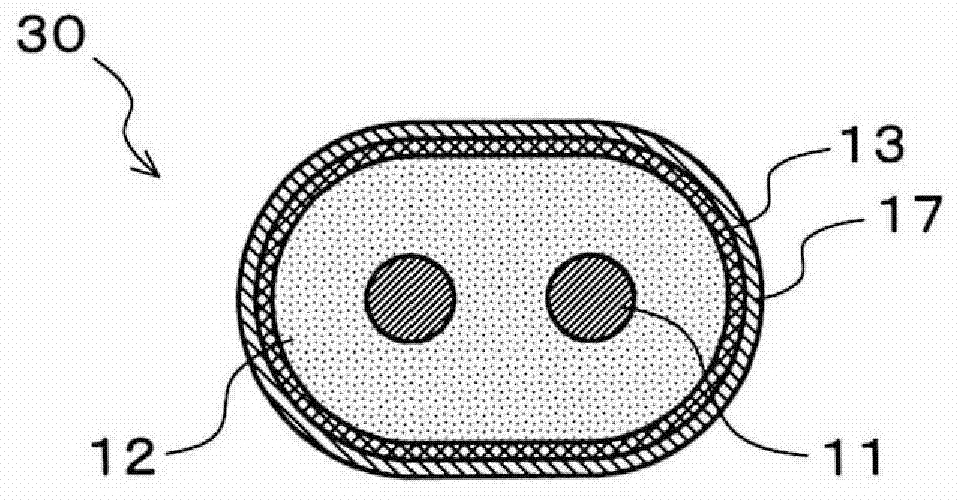

[0052] Hereinafter, best embodiments of the present invention will be described with reference to the drawings.

[0053] First, the drainless differential signal transmission cable according to the first embodiment will be described.

[0054] Such as figure 1 As shown, the drainless differential signal transmission cable 10 of the first embodiment is characterized in that it includes: a pair of signal line conductors 11 arranged in parallel; an insulator 12 provided around the pair of signal line conductors 11; The shield conductor 13 around the insulator 12; and the metal wire 15 is used to solder the shield conductor 13 to the ground (for example, a ground pad described later is mentioned, but other terminals, etc. ), the ends of a pair of signal line conductors 11 are exposed from the insulator 12 and the shield conductor 13, and the ground needle 14 has a winding portion 14a in which a part of the metal wire 15 is wound around the shield conductor 13, and a metal The en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com