Electromagnetic-coil winding and adhesive-tape coating integrated device

An electromagnetic coil and all-in-one machine technology, applied in coil manufacturing, etc., can solve problems such as difficult quality assurance, low production efficiency, coil insulation, isolation, and poor protection effects, and achieve short auxiliary waiting time, reduce production costs, and improve operations. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

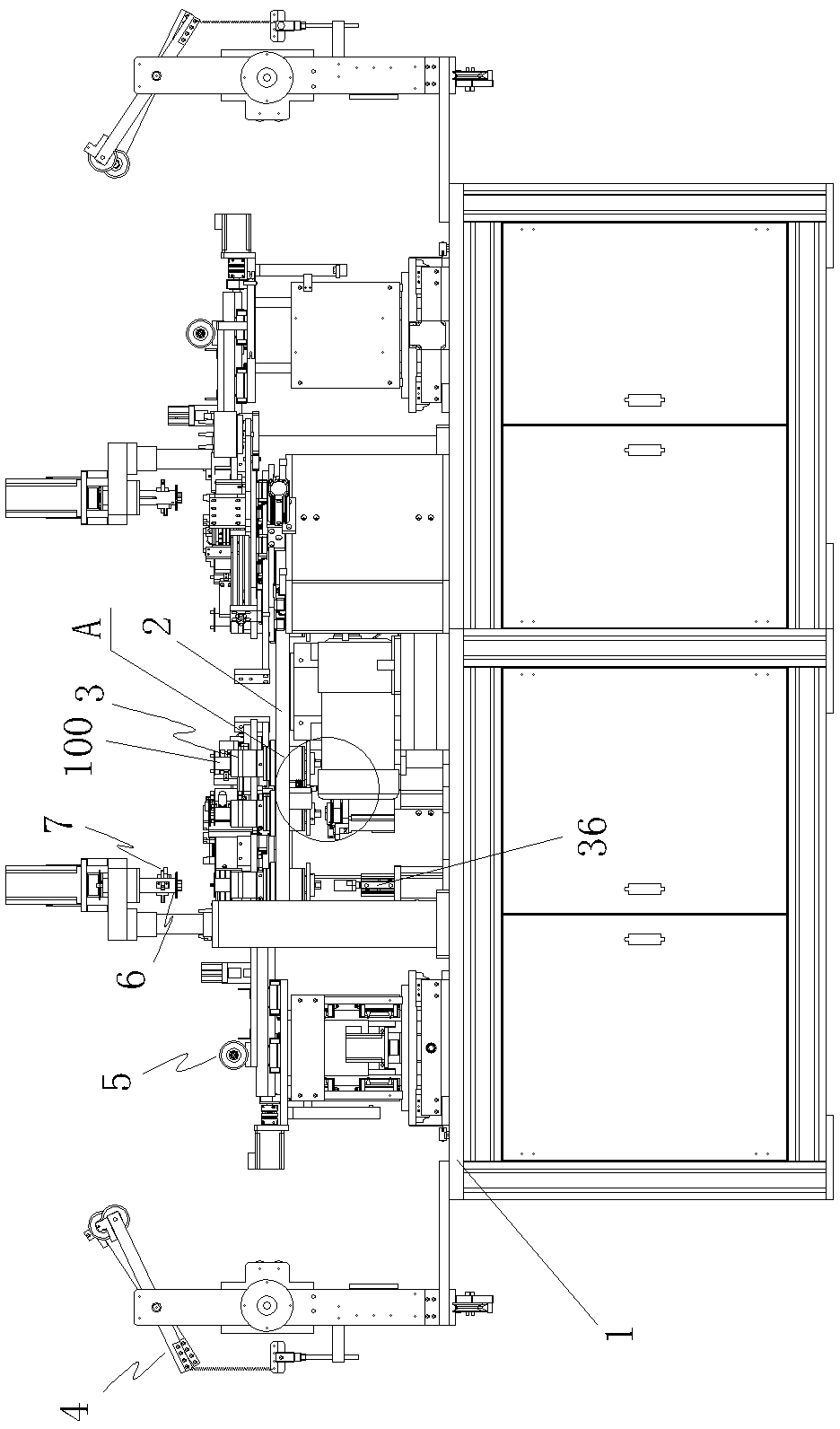

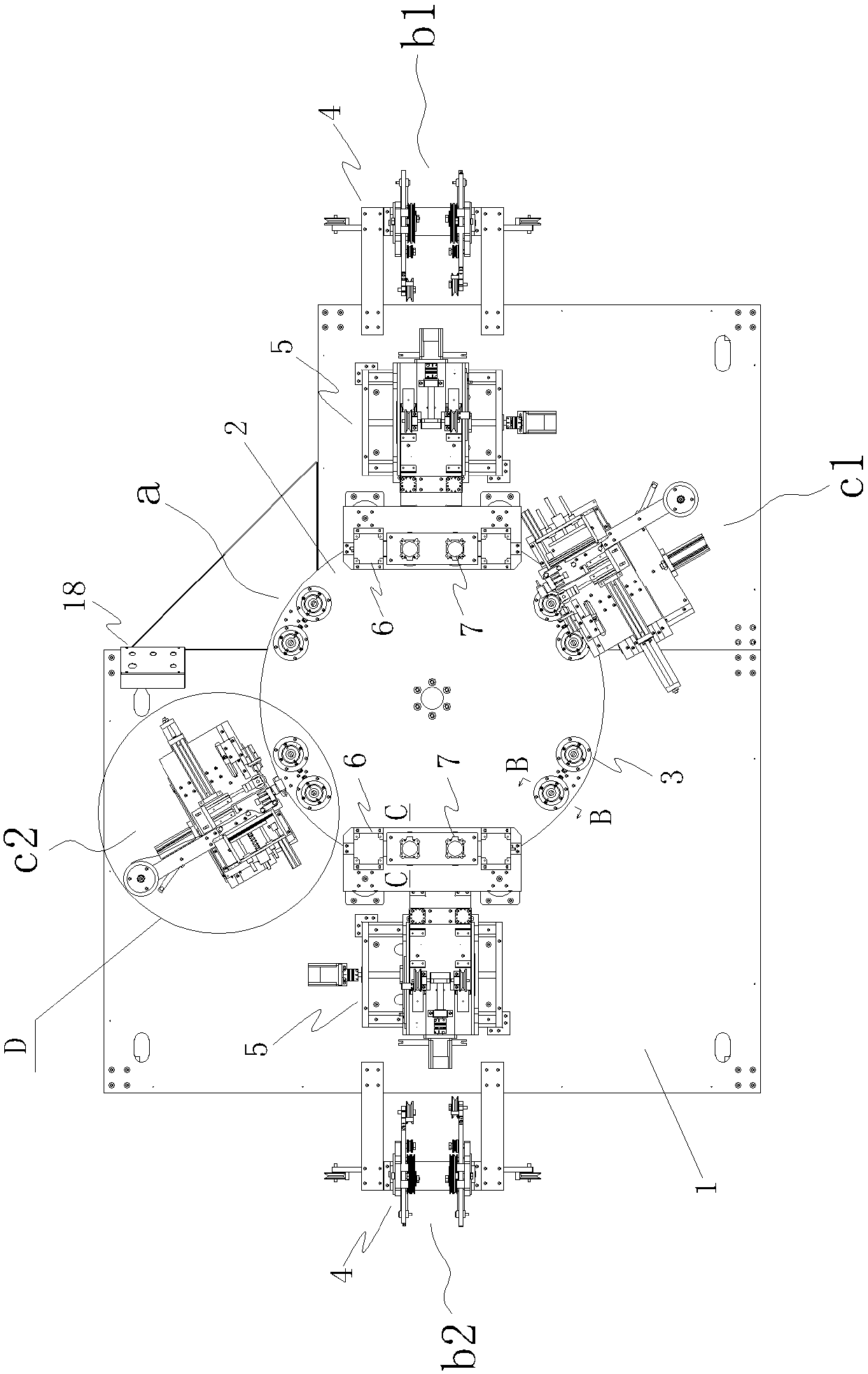

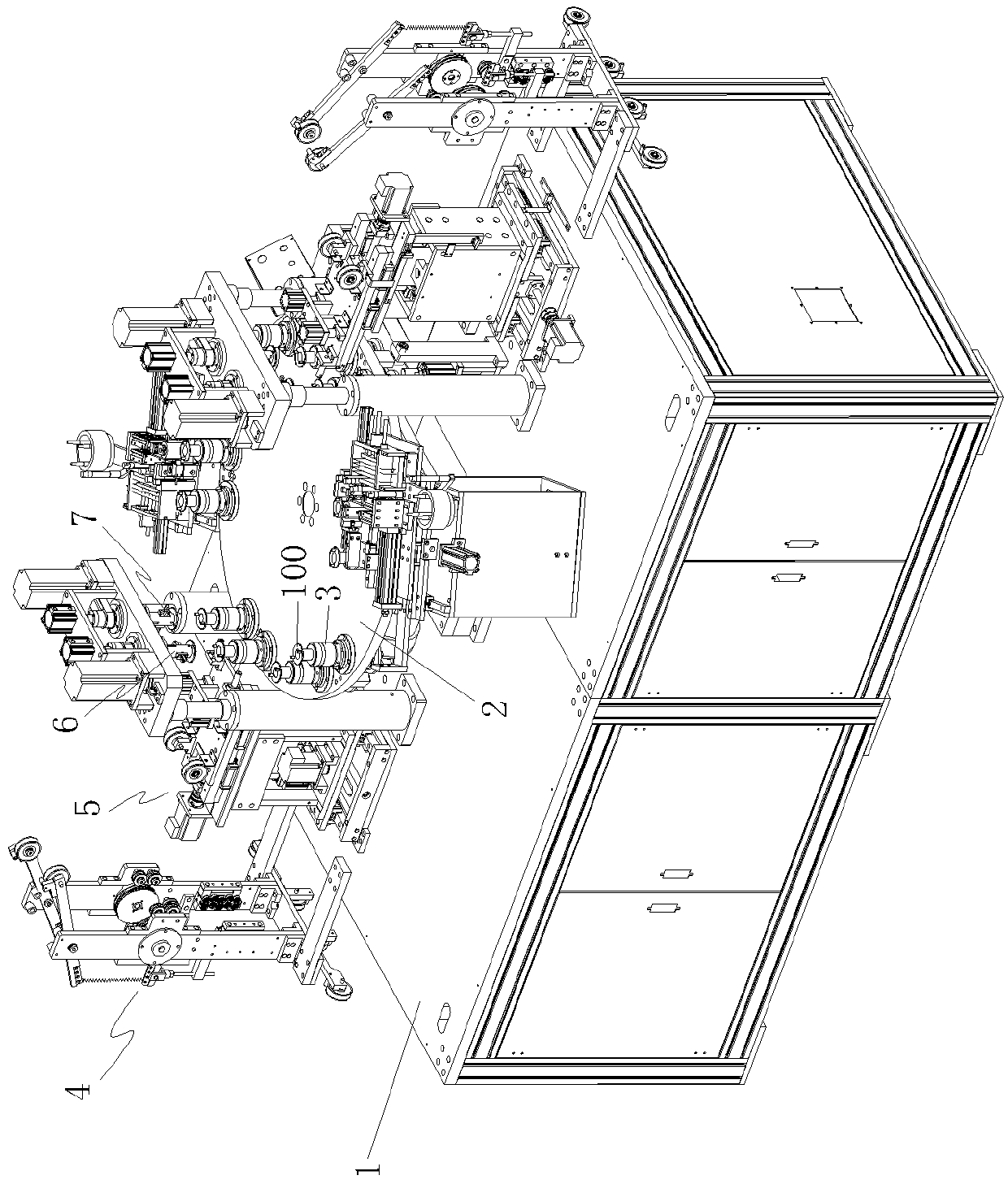

[0045] Figure 1 to Figure 12 As shown, an electromagnetic coil winding and rubber coating integrated machine includes a base 1, and an intermittently rotatable horizontal turntable 2 is arranged on the base 1. The turntable 2 can be driven by a motor and a divider to rotate intermittently along the turntable 2. In the direction of rotation, an installation station a, a first winding station b1, a first encapsulating station c1, a second winding station b2, and a second encapsulating station c2 of the coil bobbin 100 are sequentially arranged.

[0046] Each station of the turntable 2 is equipped with two clamp mechanisms 3 capable of vertically installing the coil bobbin 100. The clamp mechanism 3 enables the coil bobbin 100 to be positioned or freely rotated in the circumferential direction. The clamp mechanism 3 includes a vertical penetration A rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com