Motor rotor angle predicting device and motor rotor angle predicting method

A technology of motor rotors and predictive devices, applied in the direction of electronic commutators, etc., can solve the problems of complex installation, unadjustable measurement accuracy, and high cost, and achieve the effects of strong real-time performance, fast calculation speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

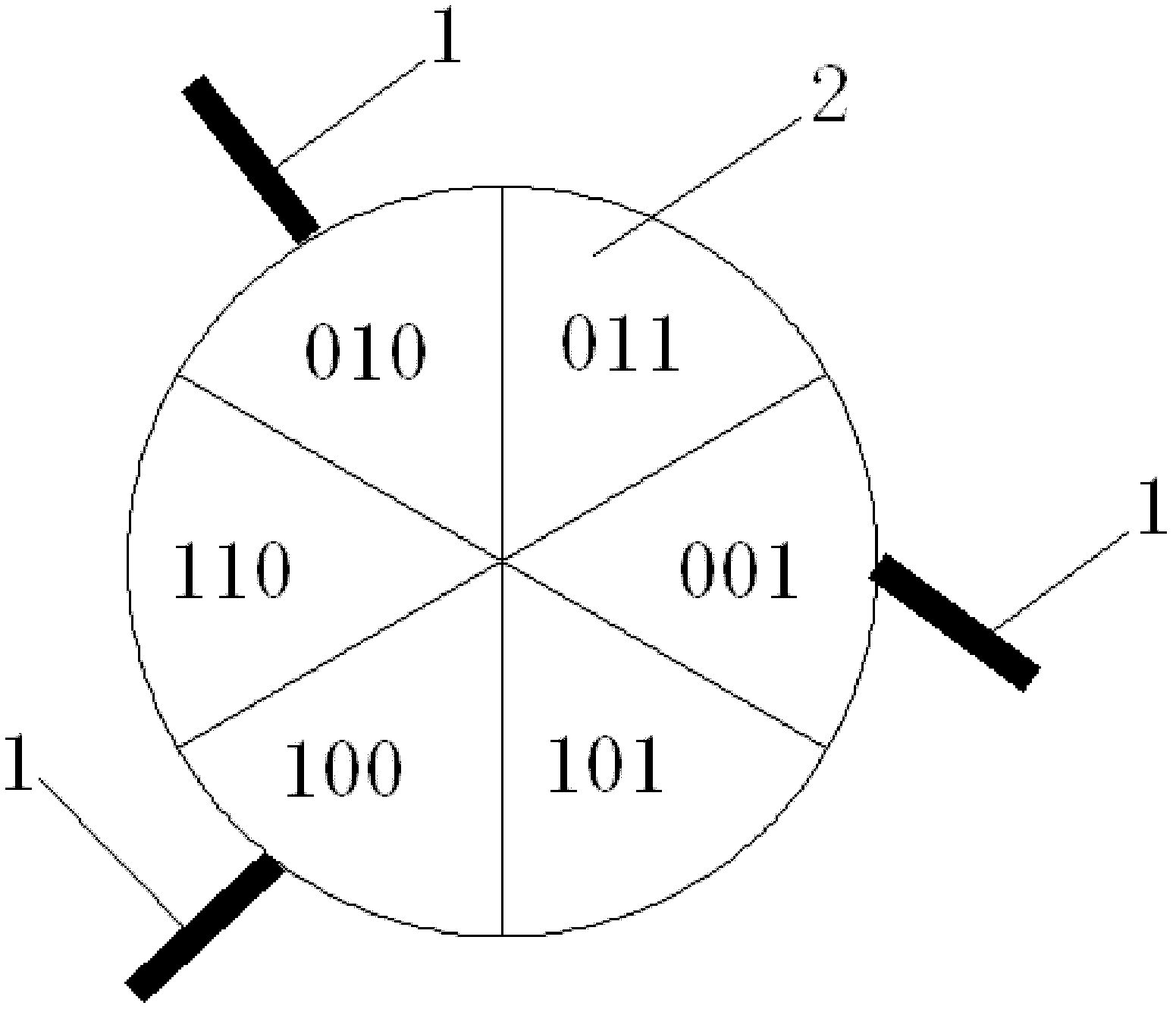

[0023] This embodiment includes a Hall sensor 1 and a micro control unit.

[0024] The Hall sensor 1 is electrically connected with the micro control unit; there are three Hall sensors 1, and they are evenly arranged around the motor rotor; the micro control unit is provided with a counting device.

[0025] The method for predicting the rotor angle of the motor using the motor rotor angle prediction device comprises the following steps:

[0026] ① According to the installation position of the motor Hall sensor 1, the interval of the motor rotor represented by the different combinations of Hall signals is preset, specifically: three Hall sensors 1 divide the circle 2 where the entire motor rotor is located into six Each interval corresponds to a combination of Hall signals.

[0027] 2. Establish a two-dimensional array storing the rotor angle value of the motor according to the interval of the rotor obtained in step 1; one of the dimensions of the two-dimensional array is dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com