Reciprocating compressor with high pressure storage vessel let down for cng station and refueling motor vehicles

一种存储容器、压缩机的技术,应用在压缩机领域,能够解决能效低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following paragraphs, the present invention is described in detail by way of example with reference to the accompanying drawings. Throughout the specification, the preferred embodiment and examples shown should be regarded as exemplifications, not limitations of the invention. As used herein, "the invention" refers to any embodiment of the invention described herein, and any equivalents thereof. Furthermore, reference throughout the text to various feature(s) of the "present invention" does not mean that all claimed embodiments or methods must include the referenced feature(s).

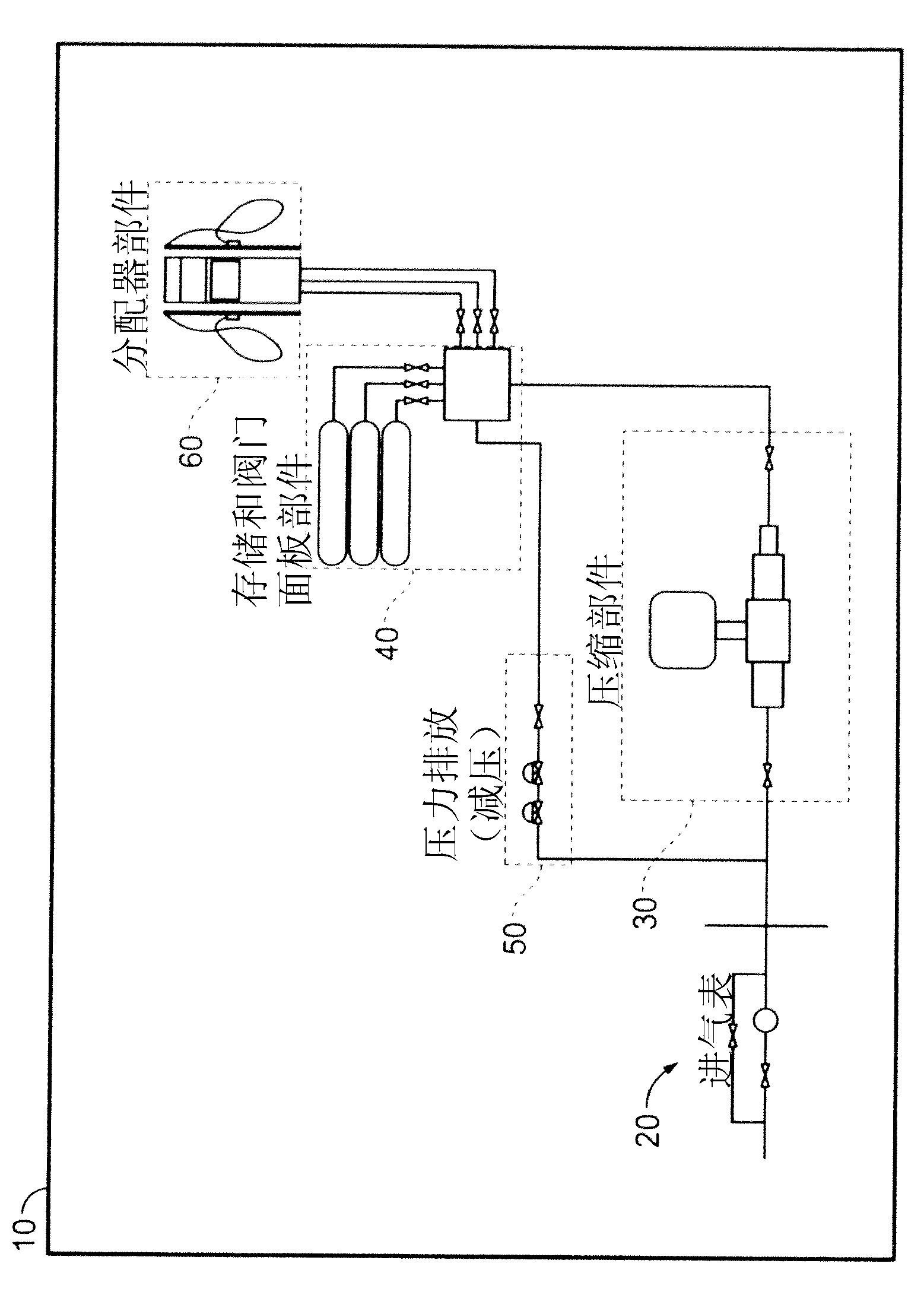

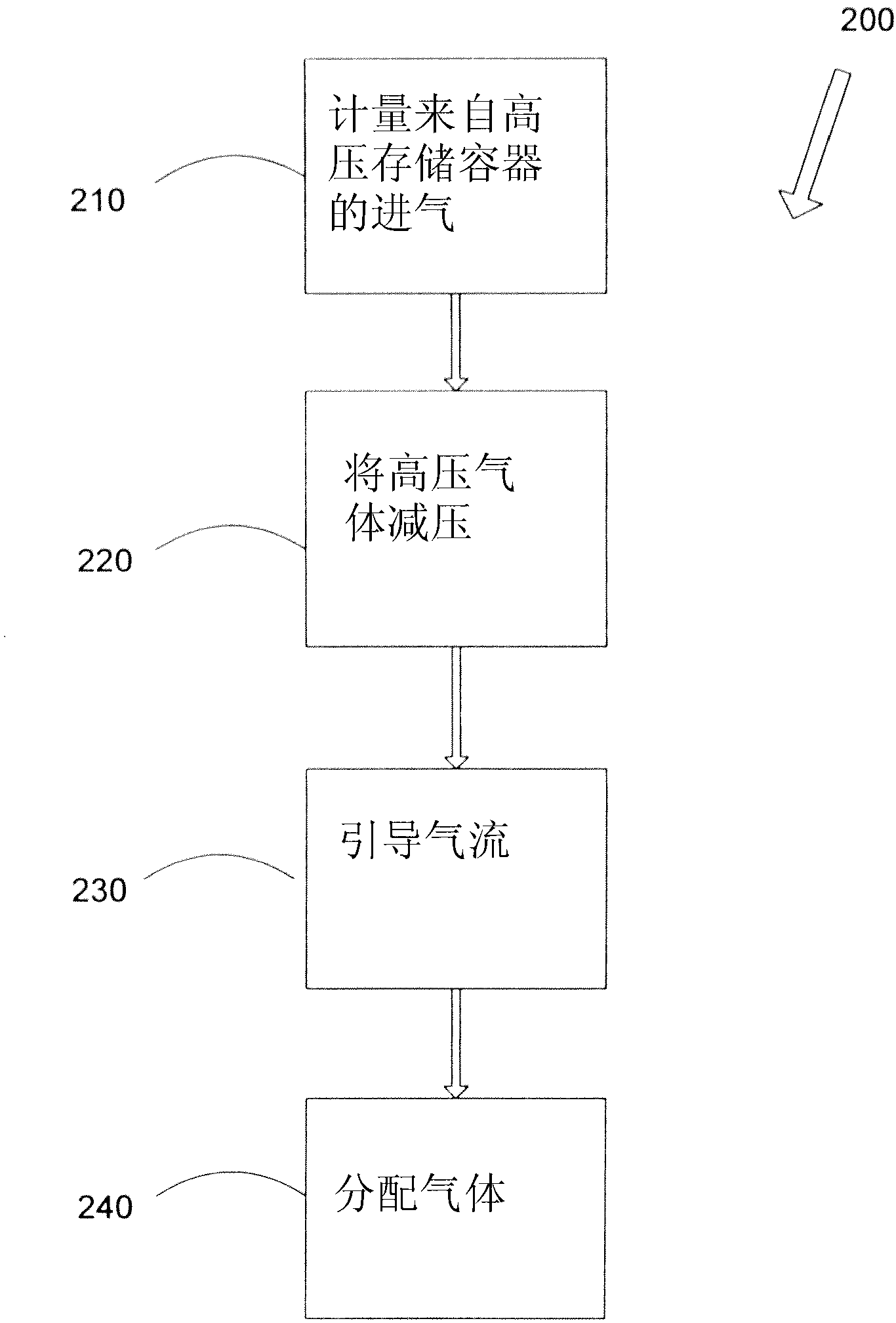

[0020] Embodiments of the present invention are directed to a reciprocating compressor with a high pressure storage vessel that decompresses a CNG station for refueling a motor vehicle, wherein the CNG station is designed to utilize intake air from a local gas company. A CNG station has the ability to increase and adjust its flow capacity by supplementing the intake air with a pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com