Silencer for a multi-leaf spring

A technology of muffler and laminated plate, applied in the direction of spring/shock absorber, leaf spring, vehicle spring, etc., can solve the problems of complex manufacturing process and large number of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

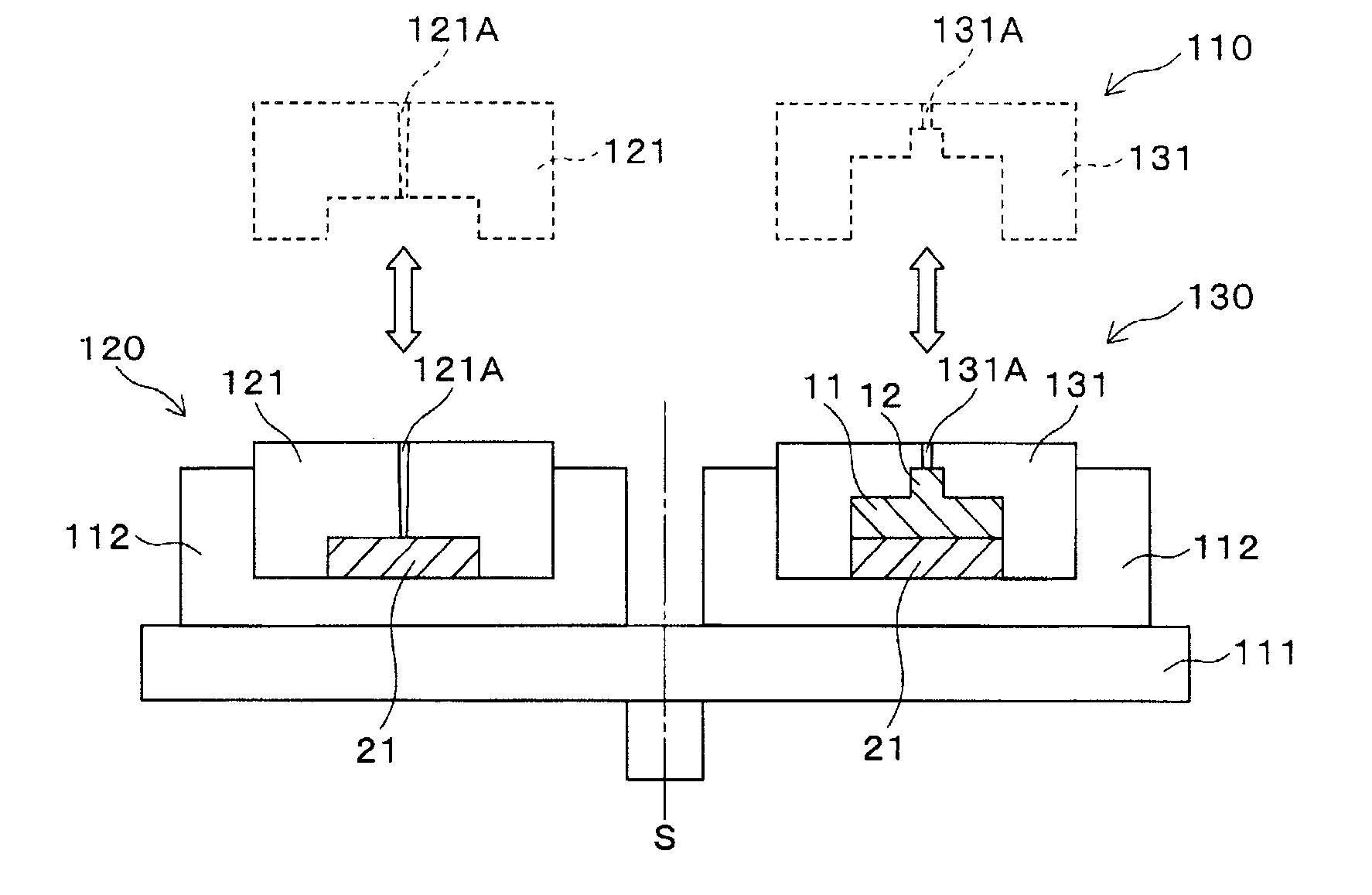

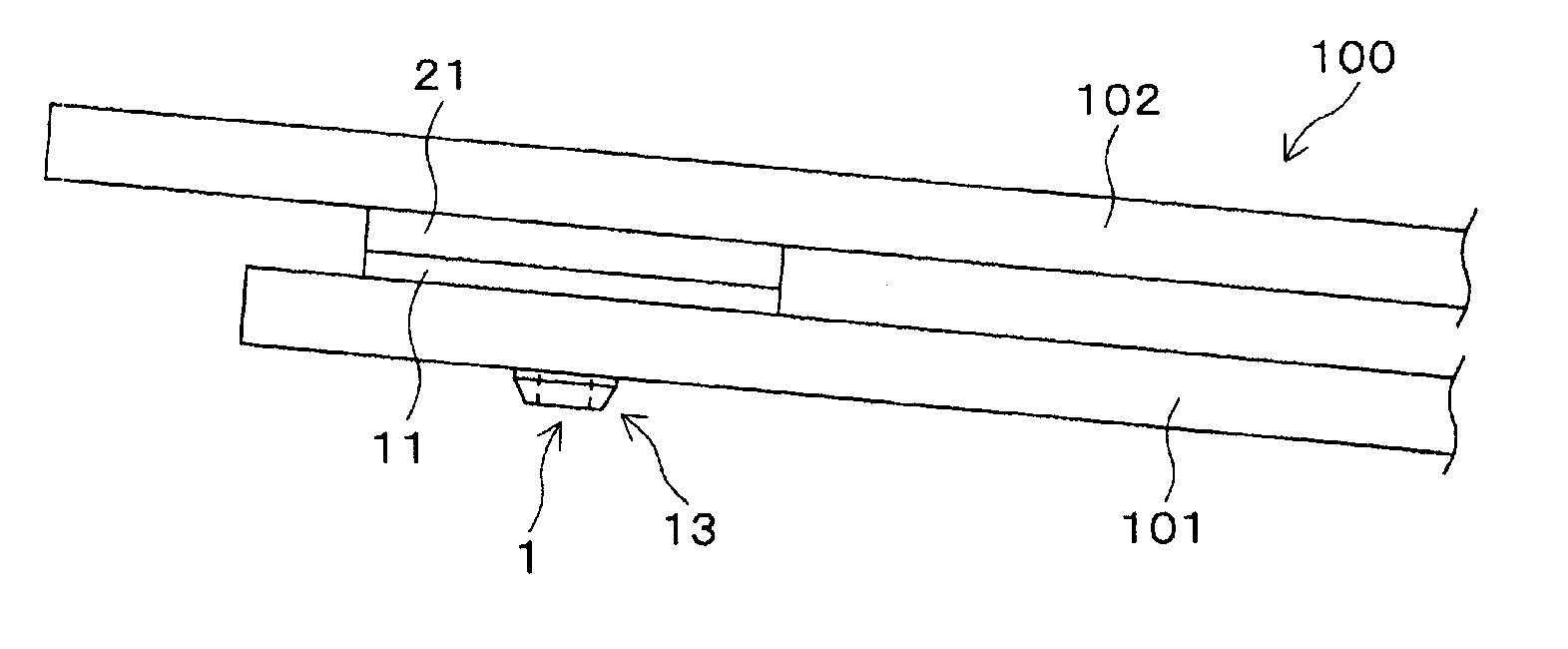

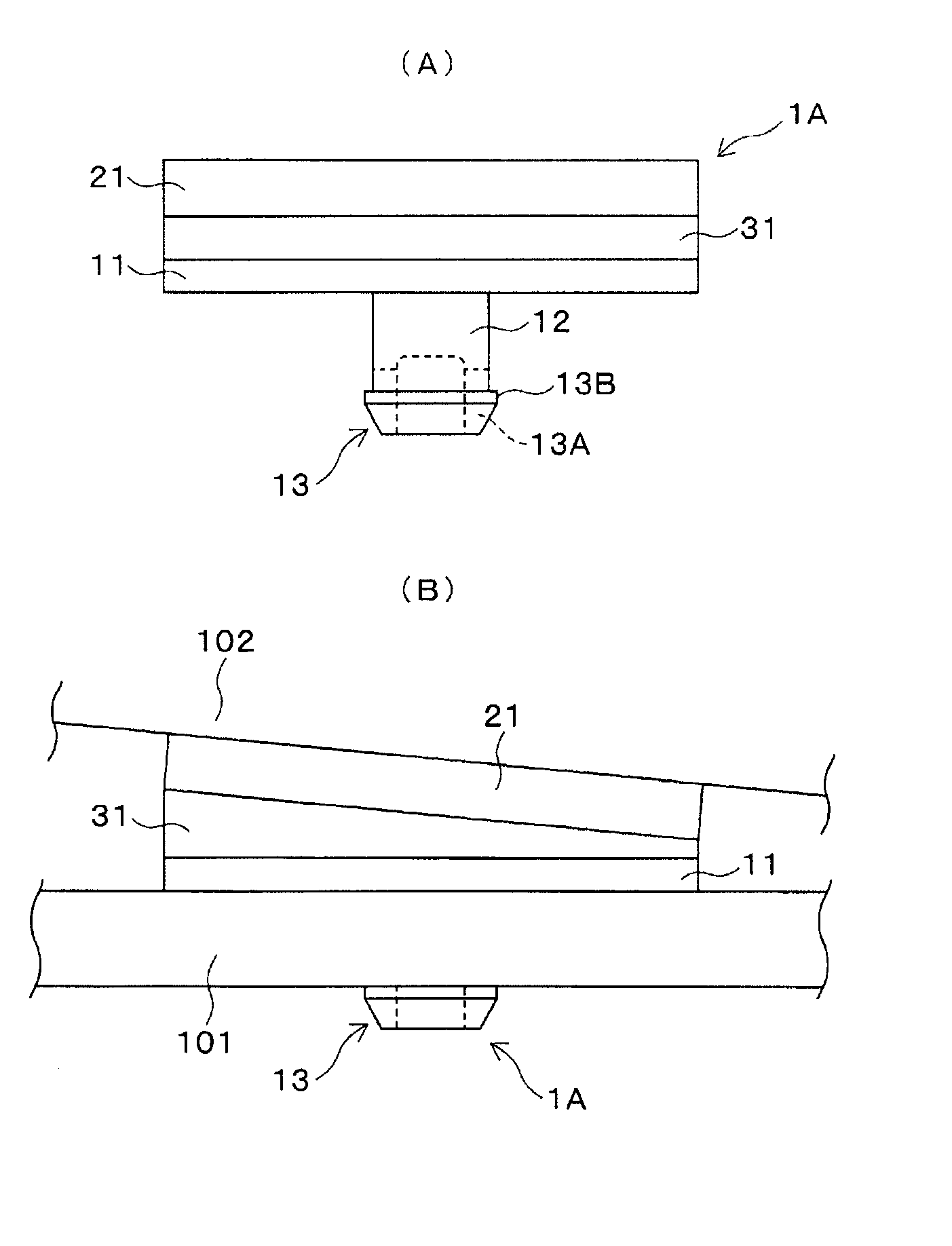

[0039] Embodiments of the present invention will be described below with reference to the drawings. figure 1 A side view showing a schematic configuration of a laminated leaf spring muffler 1 (hereinafter, muffler 1 ) according to an embodiment of the present invention is arranged between leaf springs 101 and 102 of a laminated leaf spring 100 . figure 2 means as figure 1 The shown structure of the muffler 1, (A) is a side view, (B) is an enlarged side sectional view, (C) is a plan view. figure 2 (B) is figure 2 (C) Side sectional view of line 1B-1B. The laminated leaf spring 100 is a general laminated leaf spring, in figure 1 In , only the left end portion of the laminated leaf spring 100 is shown. The muffler 1 is arranged between the ends of the leaf springs 101 and 102 of the laminated leaf spring 100 . figure 2 (C) is a plan view seen from the protrusion 12 side of the muffler 1 .

[0040] The muffler 1 has, for example, a two-layer structure having a fixed laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com