Liquid pressure generating apparatus and driving apparatus

A technology for generating devices and driving devices, which is applied in the directions of transmission devices, transmission device control, and pneumatic power devices, etc., and can solve the problems of unmentioned pump drive shaft support accuracy, unmentioned pump drive shaft, and unfound pump drive shaft support Accuracy and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

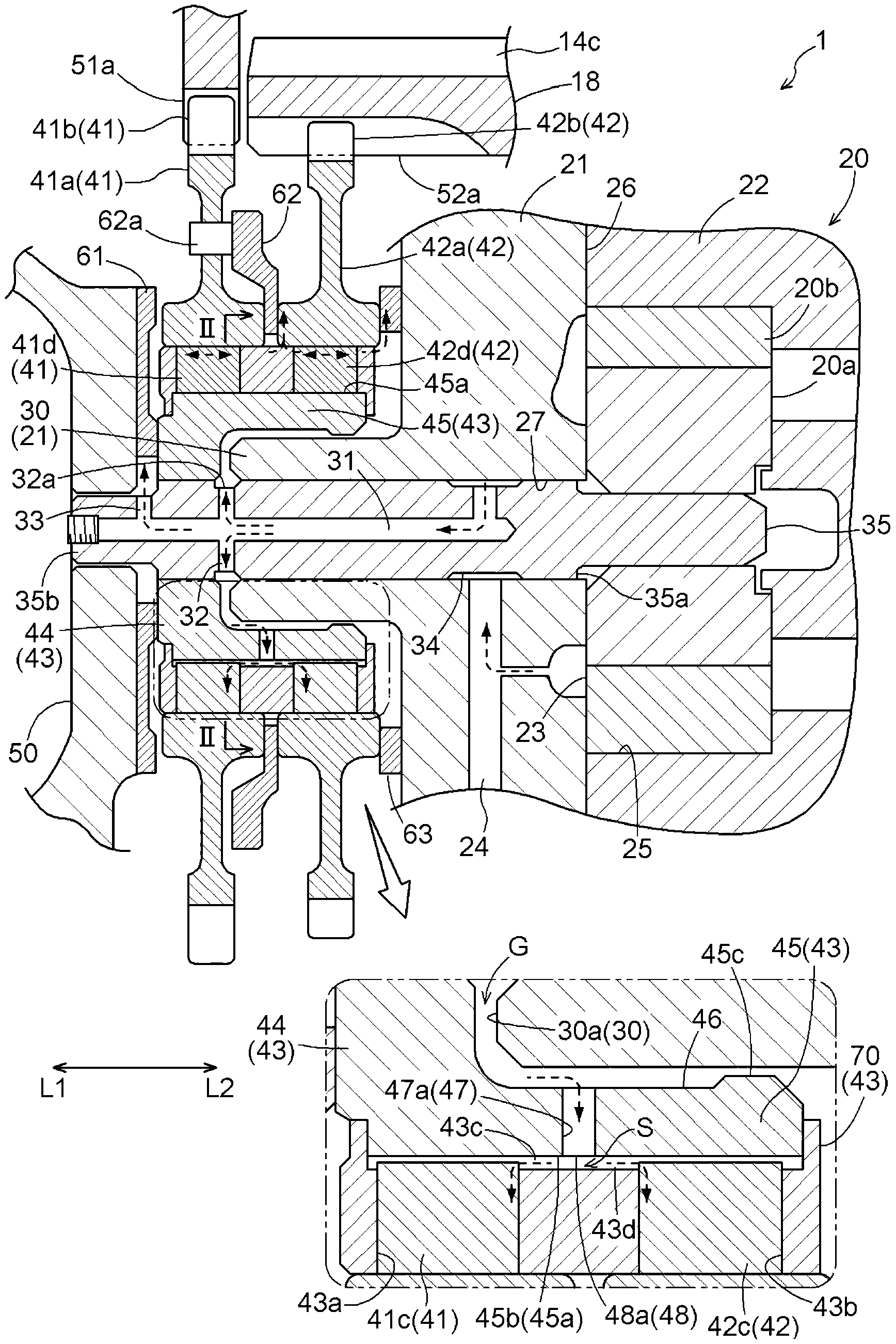

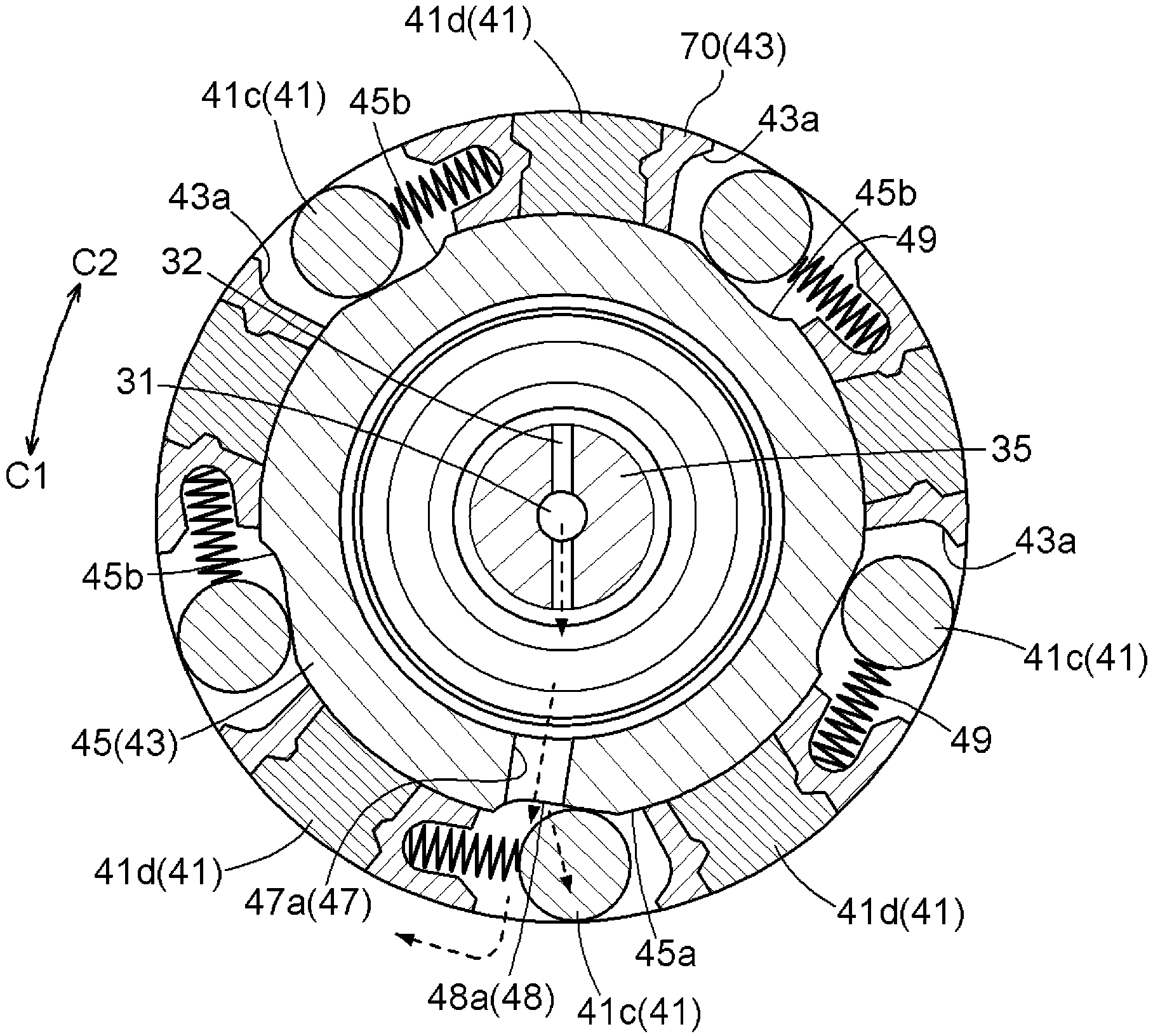

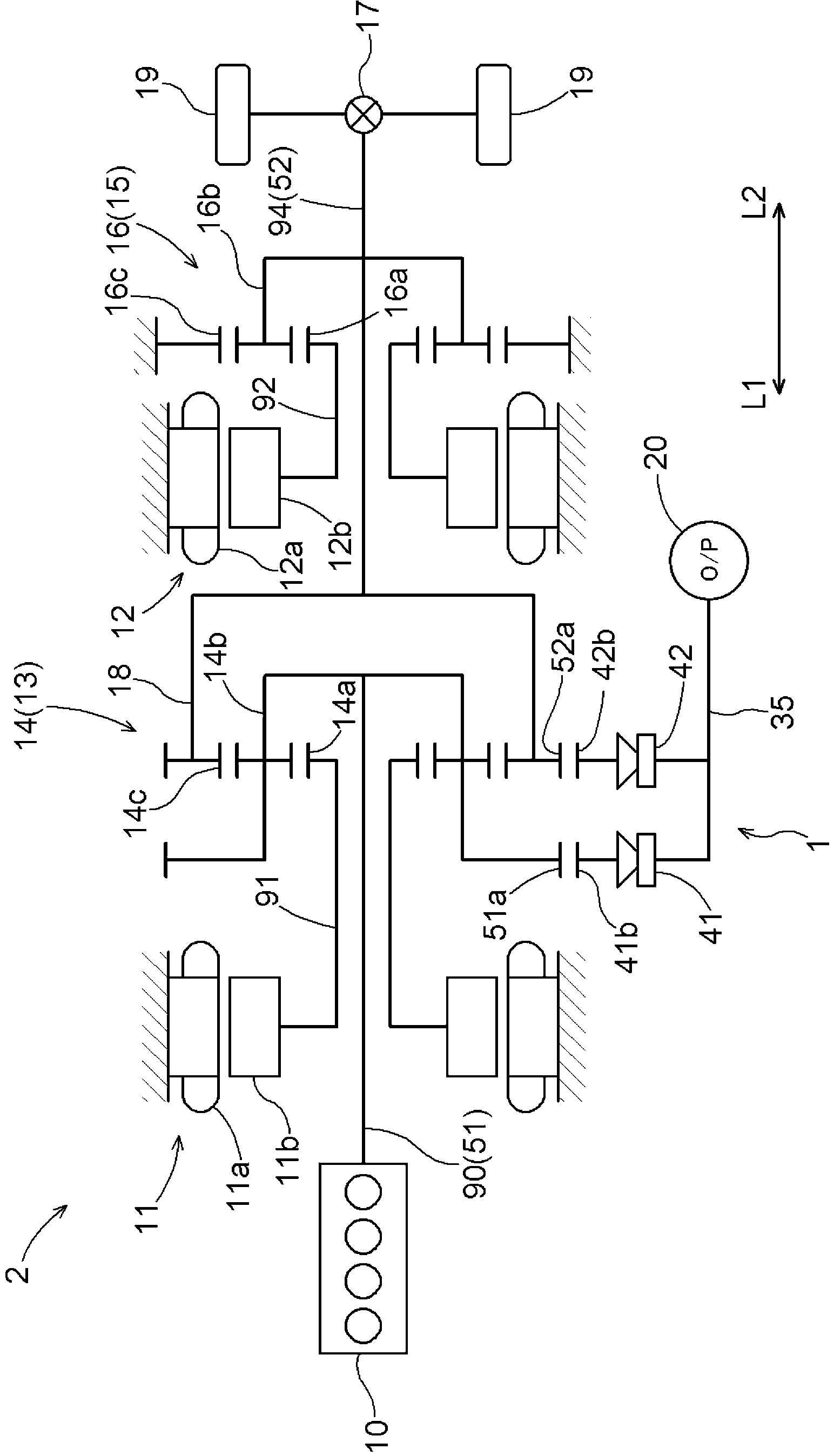

[0037] Embodiments of a hydraulic pressure generating device and a driving device according to the present invention will be described with reference to the drawings. Here, the case where the hydraulic pressure generating device of the present invention is used as a hydraulic pressure generating device for generating hydraulic pressure and the driving device of the present invention is a vehicle driving device having the hydraulic pressure generating device will be described as an example. Such as figure 1 As shown, the oil pressure generating device 1 of this embodiment has the following characteristics: the pump housings 21, 22 have the protrusions 30 radially supporting the pump drive shaft 35, and the two one-way clutches 41, 42 have respective The shared inner wheel 43 that the inner wheels of the inner wheels are integrated with each other. Also, the common inner wheel 43 has a main body portion 45 having a portion located radially outside of the protruding portion 30 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com