Leavening agent for lowering nitrate content of vegetables and method for preparing leavened vegetables by leavening agent

A technology of nitrate content and fermented vegetables, applied in the field of deep processing of vegetables, can solve problems such as toxic chemical reagents, adverse human health, etc., and achieve the effects of crisp and tender texture, pure taste and strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

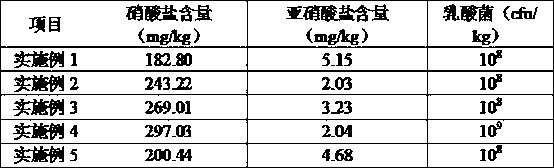

Examples

Embodiment 1

[0019] The present invention is achieved through the following technical solutions: the processing technology of low-nitrate fermented vegetables, including the following processing steps: (1) pickle 1000g of cabbage with 60g of salt for about 3 hours, wring out the water and cut it, then boil it and rinse it with cold water After draining, put it into a fermentation container and compact it; (2) Add 2500 ml of starter and mix well, seal the fermentation container, and put it in the room for fermentation. The fermentation time is two weeks at a temperature of 20-25°C; (3) Fermented vegetables are obtained after the fermentation is completed; (4) Fermented vegetables are processed, packaged and sterilized to obtain low nitrate and nitrite fermented vegetable products ;

[0020] The preparation method of the starter is as follows: add 100 grams of table salt to boil and cool to room temperature, add 20 milliliters of fermented bacteria liquid, 250 milliliters of tomato juice, 25...

Embodiment 2

[0025] The present invention is achieved through the following technical scheme: the processing technology of low-nitrate fermented vegetables, including the following processing steps: (1) marinate 1000g radish with 70g salt for about 3 hours, squeeze out the water, boil and rinse with cold water After draining, put it into a fermentation container and compact it; (2) Add 3000 ml of starter and mix well, seal the fermentation container, and put it in the room for fermentation. Ferment for 15 days at a temperature of 20-25°C; (3) Fermented vegetables are obtained after fermentation; (4) Fermented vegetables are processed, packaged and sterilized to obtain low-nitrate and nitrite vegetable products;

[0026] The preparation method of the starter is as follows: add 90 grams of table salt (3%) to boil and cool to room temperature, add 30 milliliters of fermented bacteria liquid, 250 milliliters of tomato juice, 250 grams of glucose, 500 milliliters of fish sauce, and add cold boil...

Embodiment 3

[0031] The present invention is achieved through the following technical scheme: the processing technology of low-nitrate fermented vegetables, including the following processing steps: (1) pickle 1000g cucumber with 80g salt for about 3 hours, wring out the water and divide it, then boil it and rinse it with cold water After draining, put it into a fermentation container and compact it; (2) Add 4000 ml of starter and mix well, seal the fermentation container, and put it in the room for fermentation. Ferment for 20 days at a temperature of 20-25°C; (3) Fermented vegetables are obtained after fermentation is completed; (4) Fermented vegetables are processed, packaged and sterilized to obtain low nitrate and nitrite fermented vegetable products;

[0032]The preparation method of the starter is as follows: add 80 grams of table salt (2%) to boil and cool to room temperature, add 40 milliliters of fermented bacteria liquid, 250 milliliters of tomato juice, 250 grams of glucose, 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com