Turnover robot for sweeping parallel pipes

A technology of parallel pipelines and robots, which is applied in the field of robots, can solve problems such as inconvenient transportation and storage, high power consumption, and bulky ash cleaning devices, and achieve the effects of ensuring flexibility and reliability, high work efficiency, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

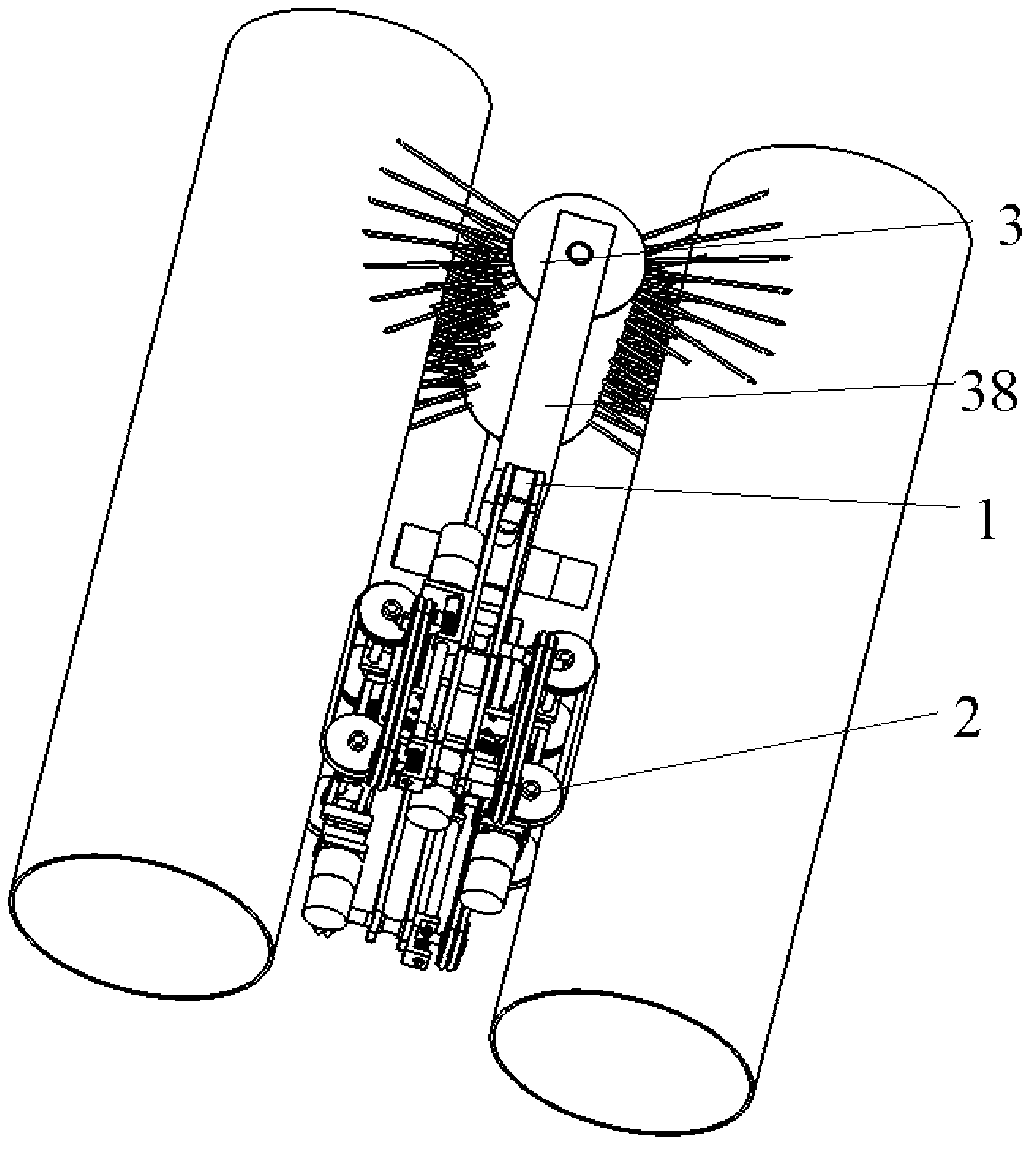

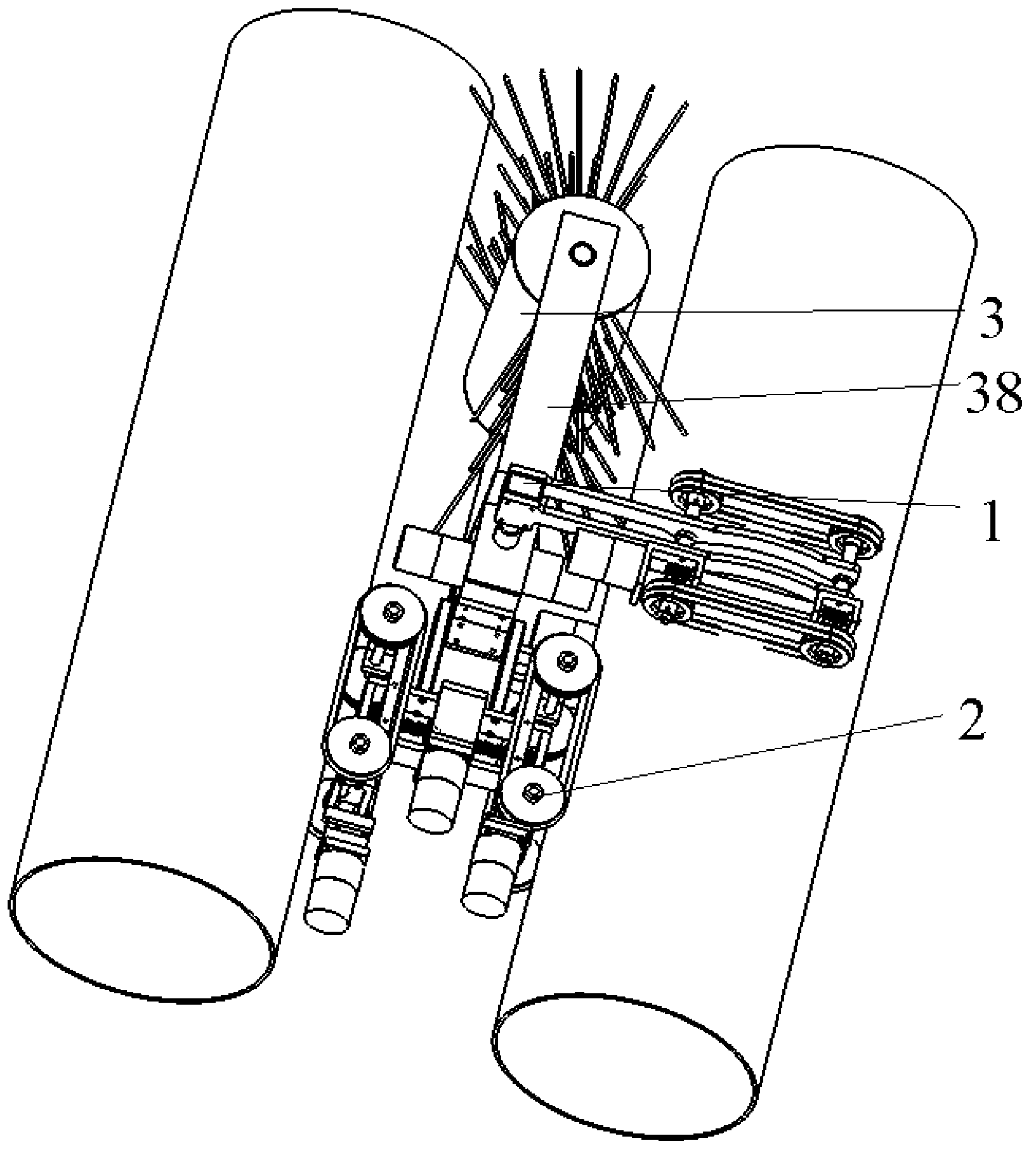

[0024] see Figure 1 to Figure 7 , a reversible parallel pipeline robot includes a walking mechanism 2 , a reversing mechanism 1 and a cleaning mechanism 3 .

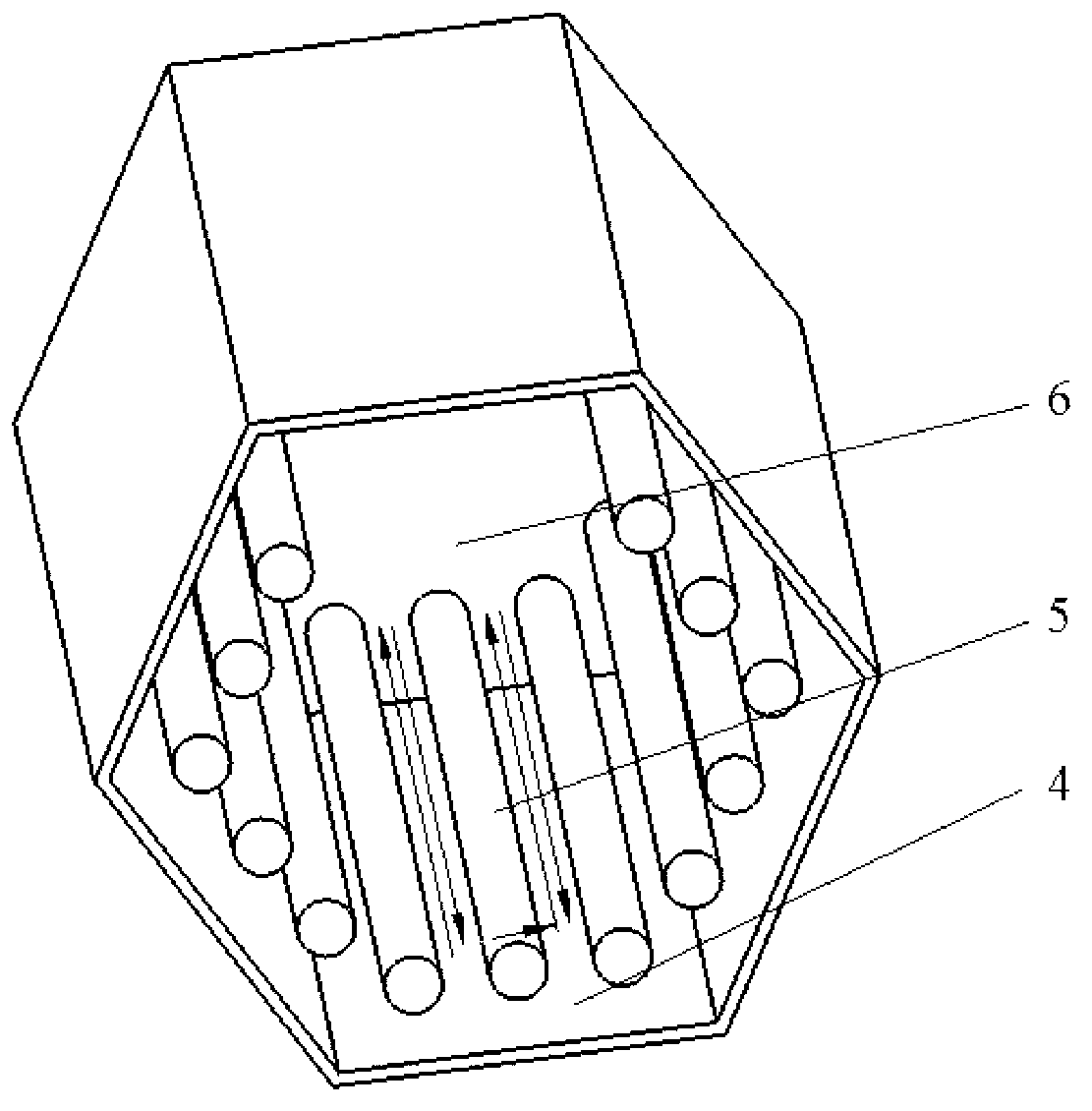

[0025] The traveling mechanism 2 includes a frame 11 and a first two-way lead screw 12, the first two-way lead screw 12 is rotatably connected to the frame 11, and the first two-way lead screw 12 is connected with two nuts 16 arranged symmetrically in opposite directions. , the nut 16 is fixedly connected with a wheel frame 15, a crawling pulley shaft 9 is respectively installed at the front and back of the wheel frame 15, and a crawling pulley 8 is respectively installed at both ends of each crawling pulley shaft 9, and two crawling pulleys on the same side of the same wheel frame are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com