Numerical control coil machine and method for continuously processing coil by using same

The technology of coil and numerical control device is applied in the field of metal wire processing equipment, which can solve the problems of low production precision, complicated coil, and increase of labor cost, and achieve the effect of reducing manpower and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

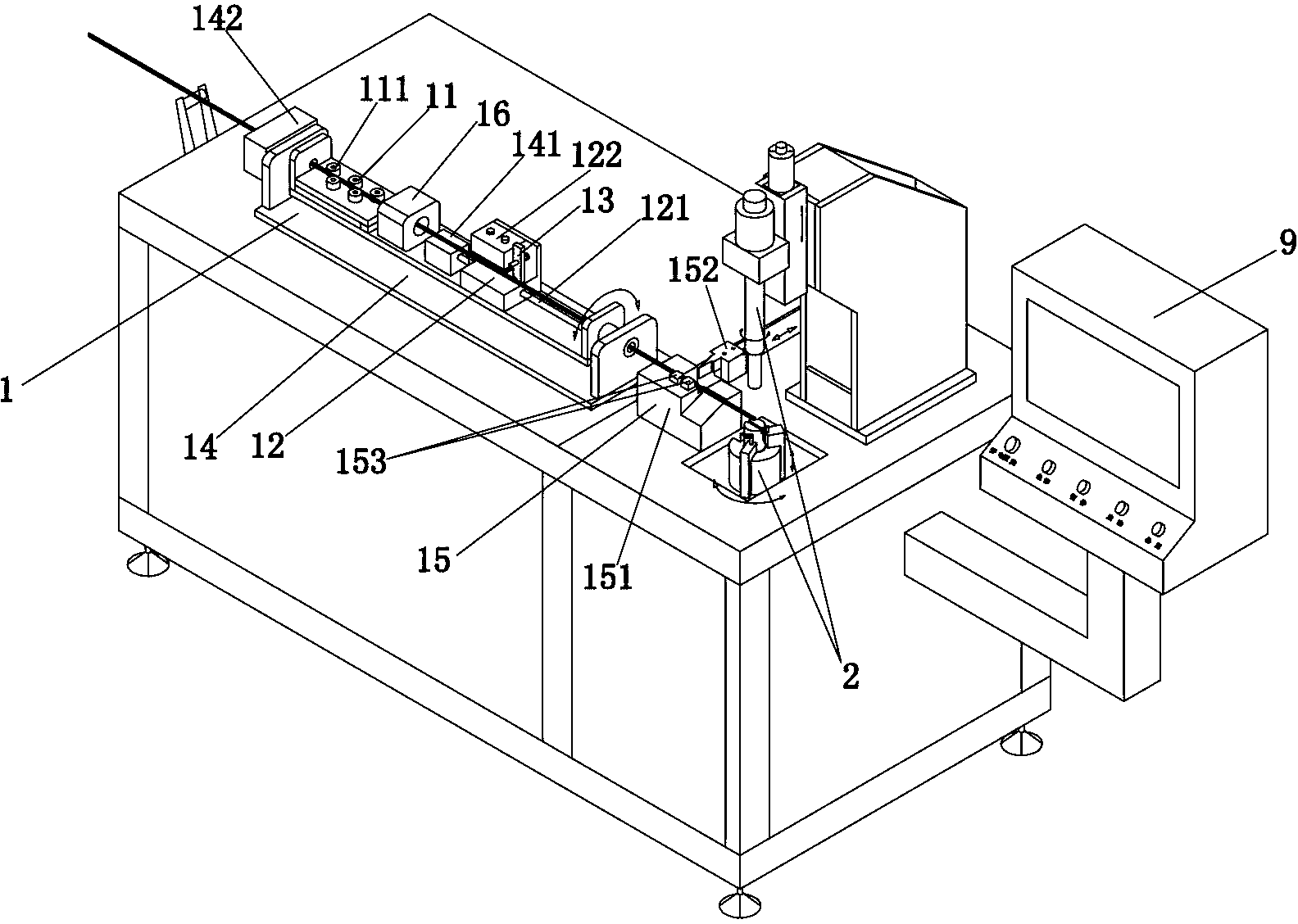

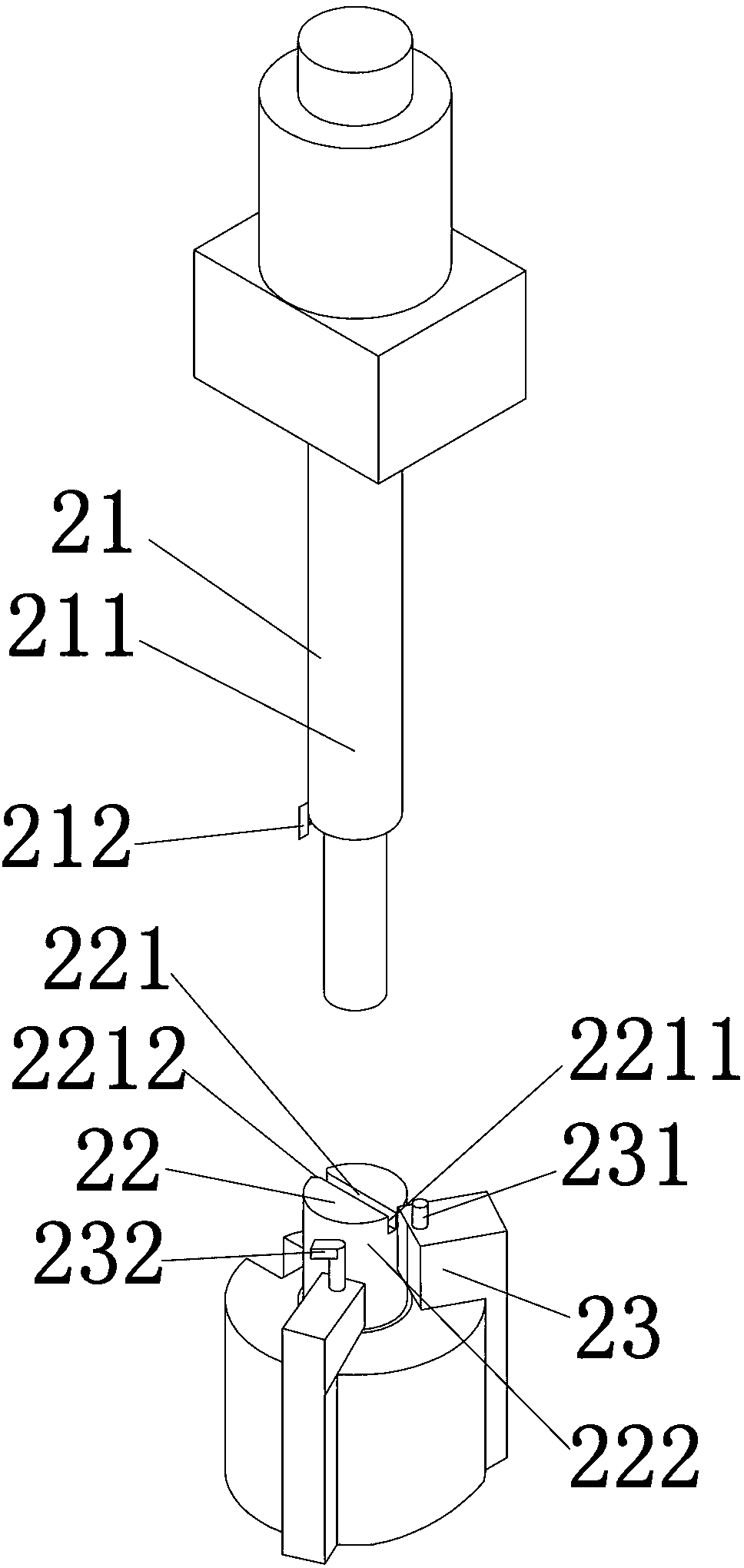

[0020] Such as figure 1 As shown, the embodiment of the numerical control coil machine of the present invention includes a numerical control device 9 , a wire feeding mechanism 1 and a bending mechanism 2 , and the numerical control device 9 controls the operation of the wire feeding mechanism 1 and the bending mechanism 2 .

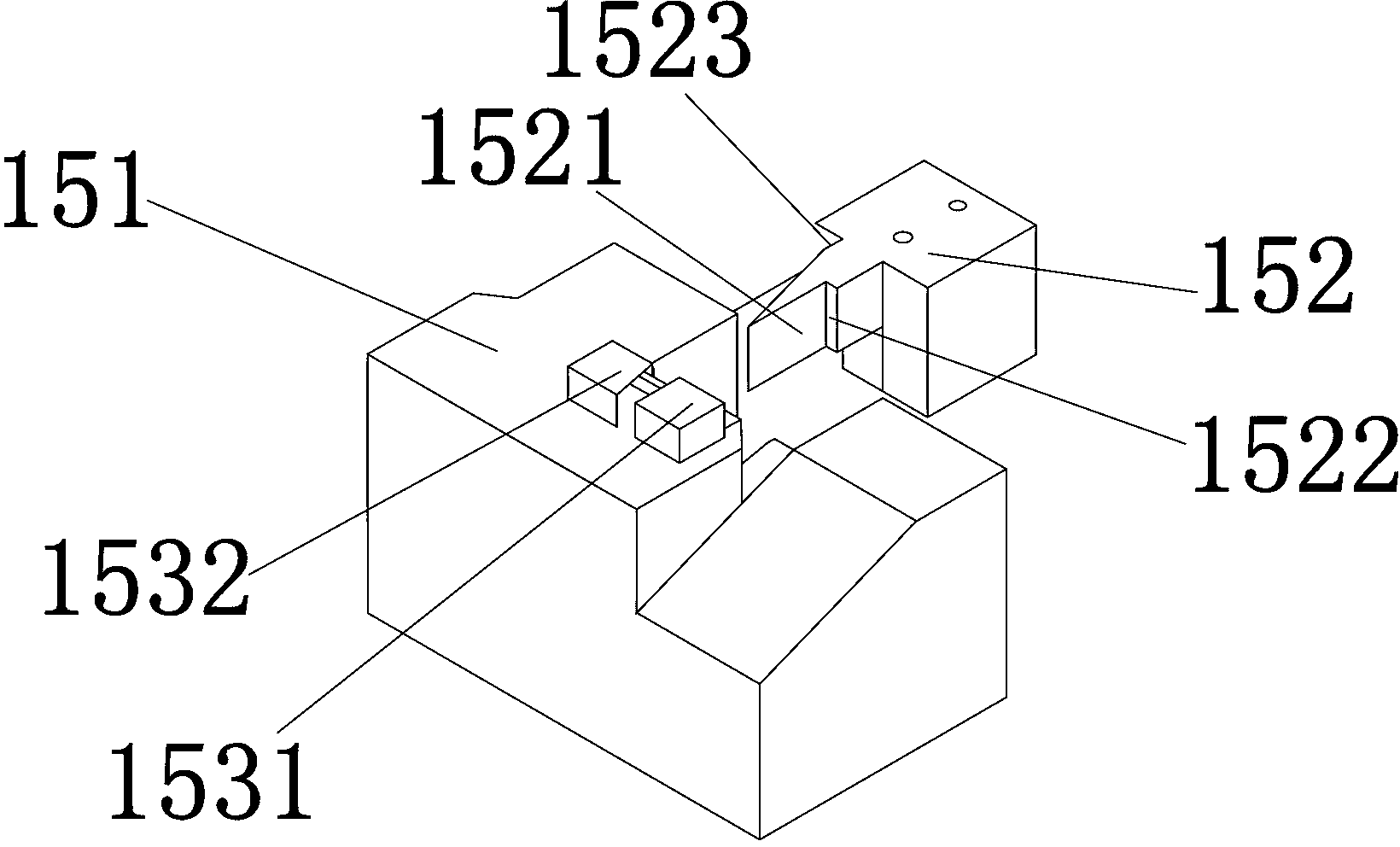

[0021] The wire feeding mechanism 1 includes a straight base line of travel, a straightening device 11 for adjusting the metal wire rod to a straight line, a wire feeder 12 for driving the metal wire rod to move linearly on the travel base line, a backstop device 13 for preventing the metal wire rod from retreating, and a wire feeder 13 for driving the metal wire rod The rotating base 14 that rotates on the base line of travel and the wire cutting base 15 that cuts the metal wire.

[0022] The traveling baseline is a virtual straight line set in the wire feeding mechanism 1, and the metal wire coincides with the traveling baseline from entering the wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com