Multilevel-positioning scraping plate of rotary cutter

A knife row and rotary knife technology is applied to multi-stage positioning scraping of rotary knives. It can solve the problems that affect the manufacturing cost of product headers and the manufacturing cycle of product headers, and achieve the effect of being convenient for large-scale use, low manufacturing cost, and easy to take out and operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

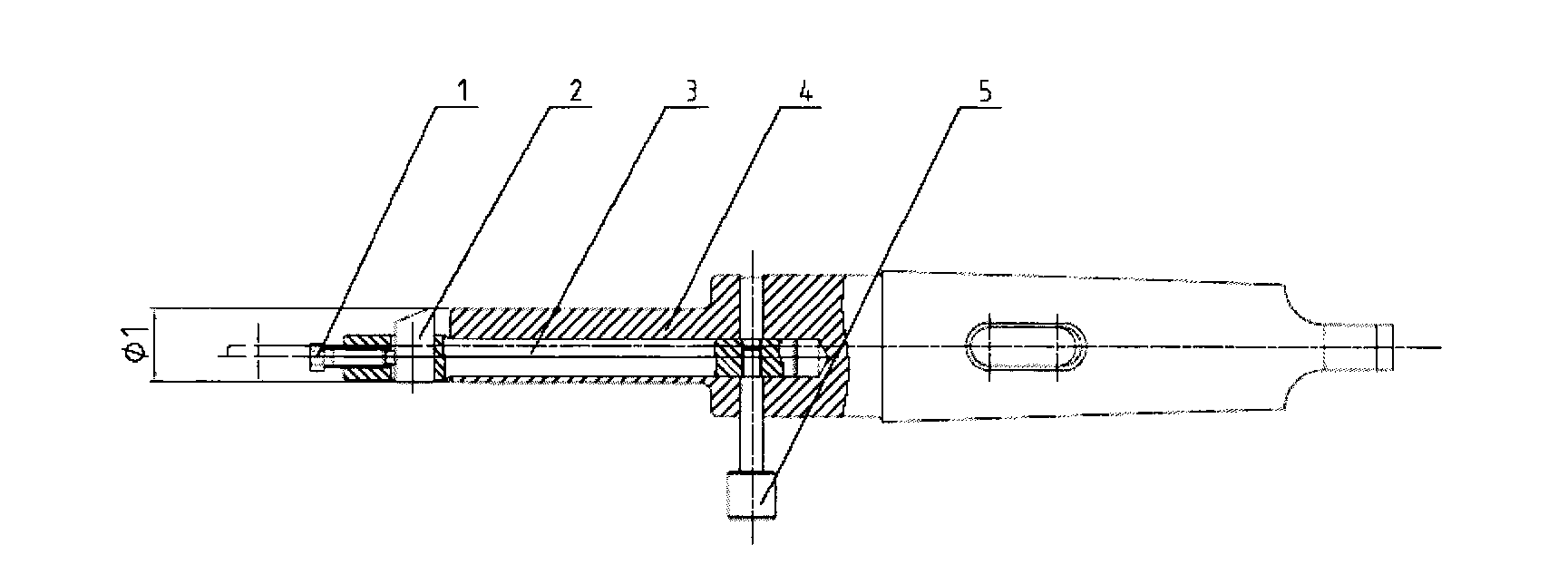

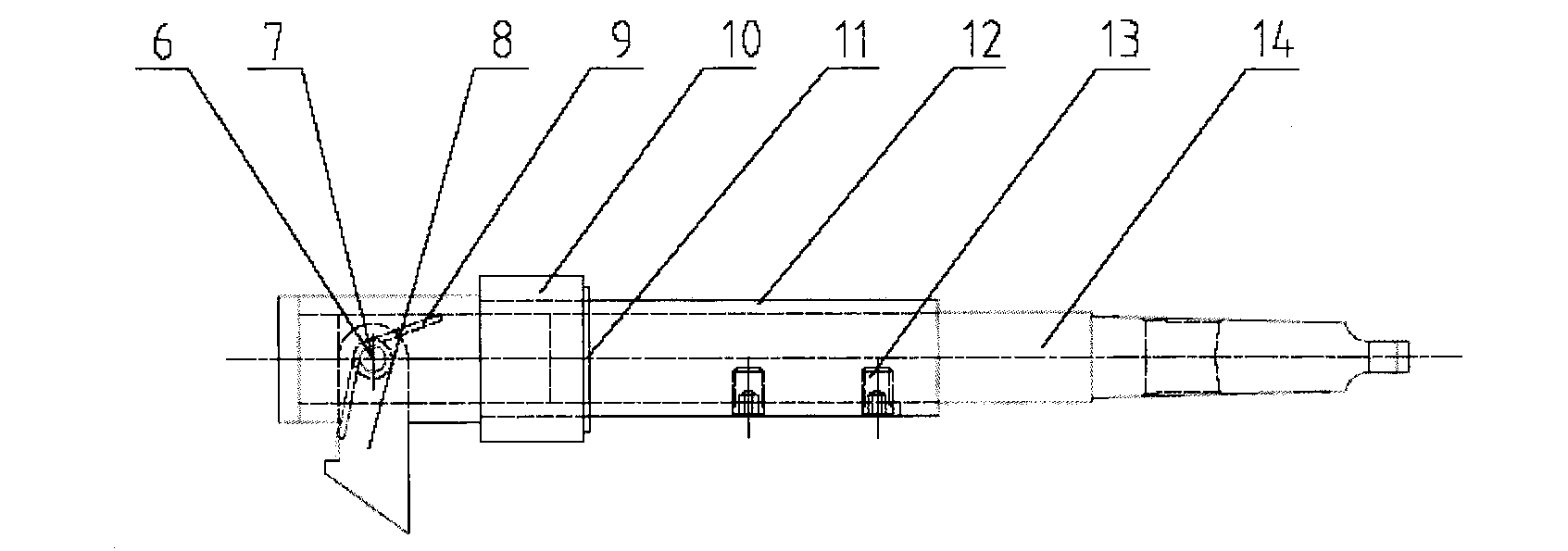

[0048] Such as figure 2 As shown, it is a side view of the first rotary knife multi-stage positioning scraper. The rotary knife multi-stage positioning scraper includes a pin shaft 6, a cotter pin 7, a flip scraper 8, a torsion spring 9, a positioning ring 10, and a retaining ring 11. Sliding sleeve 12, hexagon socket set screw 13 and first knife row body 14.

[0049] Such as image 3 As shown, the first knife row body 14 has a knife-mounting groove, and a turning scraper 8 is arranged in the knife-mounting groove, and the turning scraper 8 is fixed in the knife-mounting groove of the first knife-row body 14 through the pin shaft 6 and the cotter pin 7, and the flipping A torsion spring 9 is embedded in the center hole of the scraper 8, the lower end of the torsion spring 9 is buckled on the turning scraper 8, and the upper end of the torsion spring 9 is buckled on the first knife row body 14, and the first knife row body 14 is provided with a slip The sleeve 12, through th...

Embodiment 2

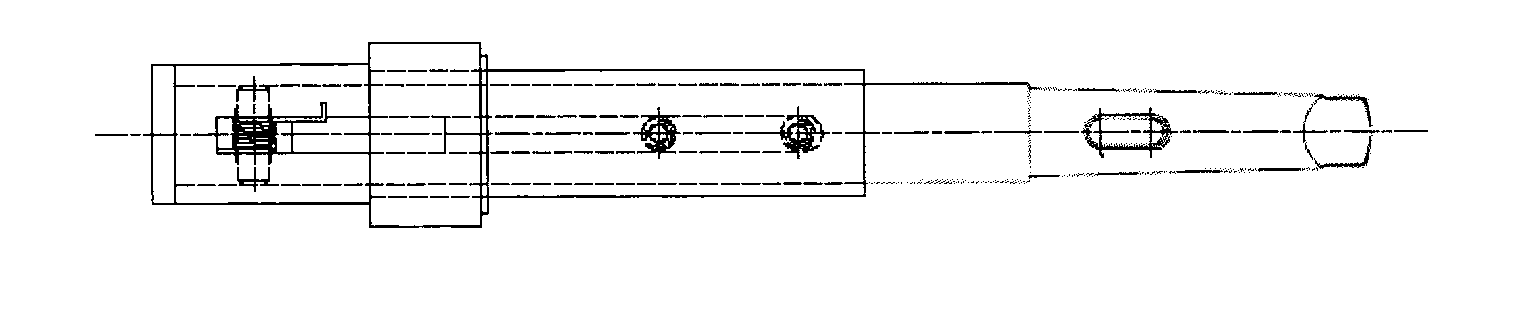

[0058] Such as Figure 14 As shown, it is a side view of the second rotary knife multi-stage positioning scraper. The rotary knife multi-stage positioning scraper includes a retaining ring 10, a positioning ring 15, a pin shaft 6, a cotter pin 7, a flat scraper 16, and a torsion spring. 9. The sliding bushing 17 and the second blade row body 18 .

[0059] Such as Figure 15 As shown, the second knife row body 18 has a knife-mounting groove, and a flat scraper 16 is arranged in the knife-mounting groove. A torsion spring 9 is embedded in the central hole of the scraper 16, the lower end of the torsion spring 9 is buckled on the flat scraper 16, and the upper end of the torsion spring 9 is buckled on the second knife row body 18, and the second knife row body 18 is provided with a sliding The bushing 17 can press the flat scraper 16 into the knife slot through the sliding of the sliding bushing 17 , and a positioning ring 15 is provided on the outside of the second knife row b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com