Brake hub honing head with improved structure

A technology of brake hub and honing head, which is applied in the field of brake hub honing head, can solve the problems of small bottom and cannot meet the technical requirements of parts, and achieve the effect of ensuring cylindricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

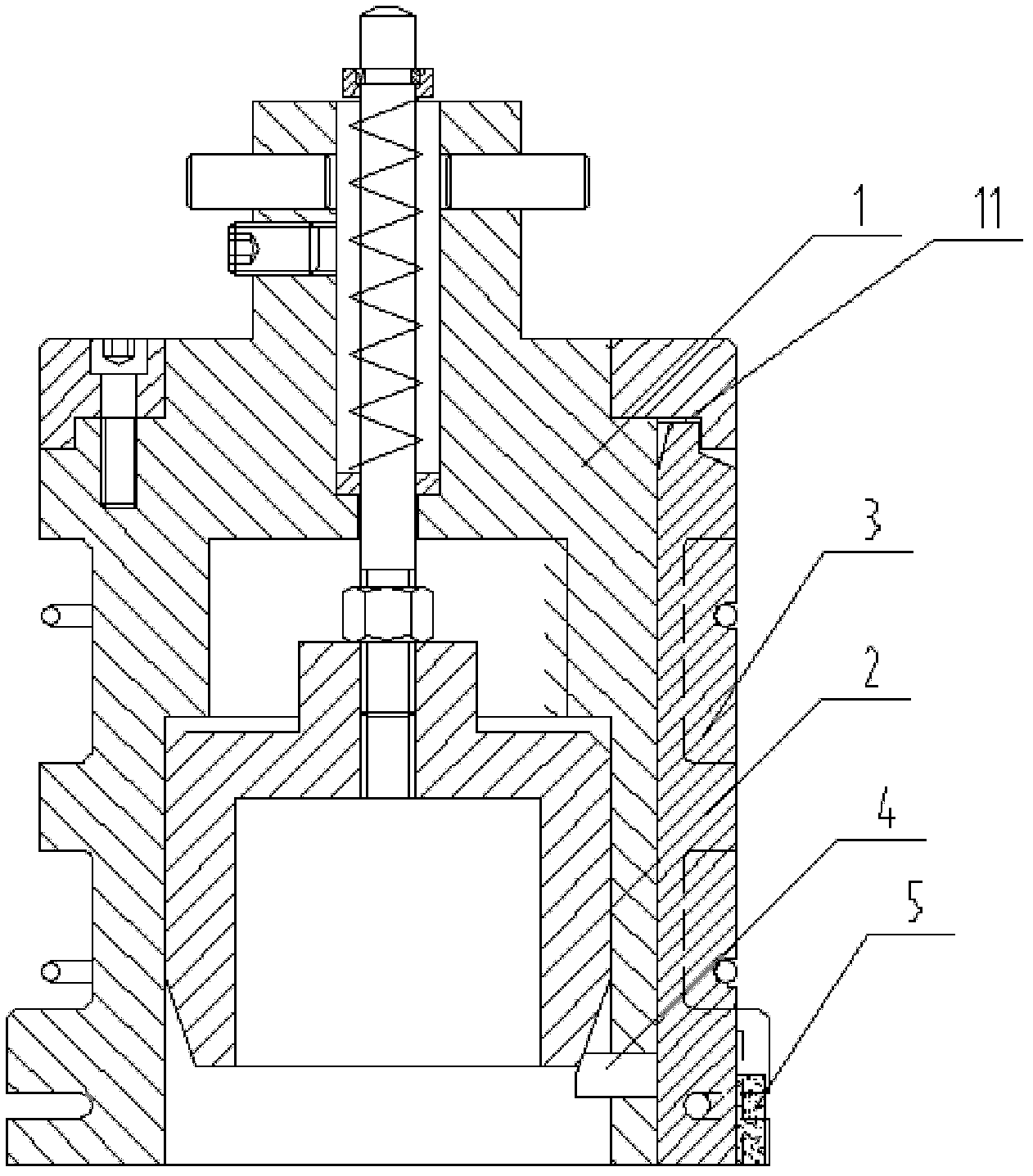

[0013] Embodiment: A honing head for a brake hub with improved structure, including a casing 1, an adjusting mandrel 2, a sand bar seat 3, a top pin 4 and a sand bar 5, and the adjusting mandrel 2 can rotate in the circumferential direction and can be elastically moved and positioned in the axial direction In the outer casing 1, at least one sand bar seat 3 is located outside the outer casing 1, and a radial perforation is provided on the side wall of the outer casing 1, and the ejector pin 4 is movably inserted into the through hole, and one end of the ejector pin 4 stops on the outer side of the adjustment mandrel 2 wall, the other end of the ejector pin 4 is tightly abutted on the inner side wall of one end of the sand bar seat 3, and the sand bar seat 3 is fixed on the outer side wall of the sand bar 5, and the outer side wall of the adjusting mandrel 2 is a tapered surface with a tapered outer diameter at one end. The other end of the sand bar seat 3 is hingedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com