Rolling mill supporting roll precise grinding method

A technology of precision grinding and supporting rollers, applied in the field of grinding processing, can solve the problems of poor coaxiality and cylindricity accuracy, achieve precise support, eliminate the influence of grinding accuracy, and reduce errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

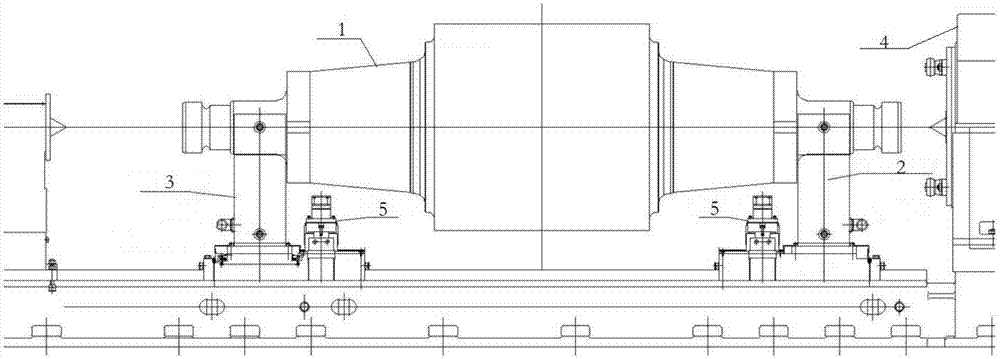

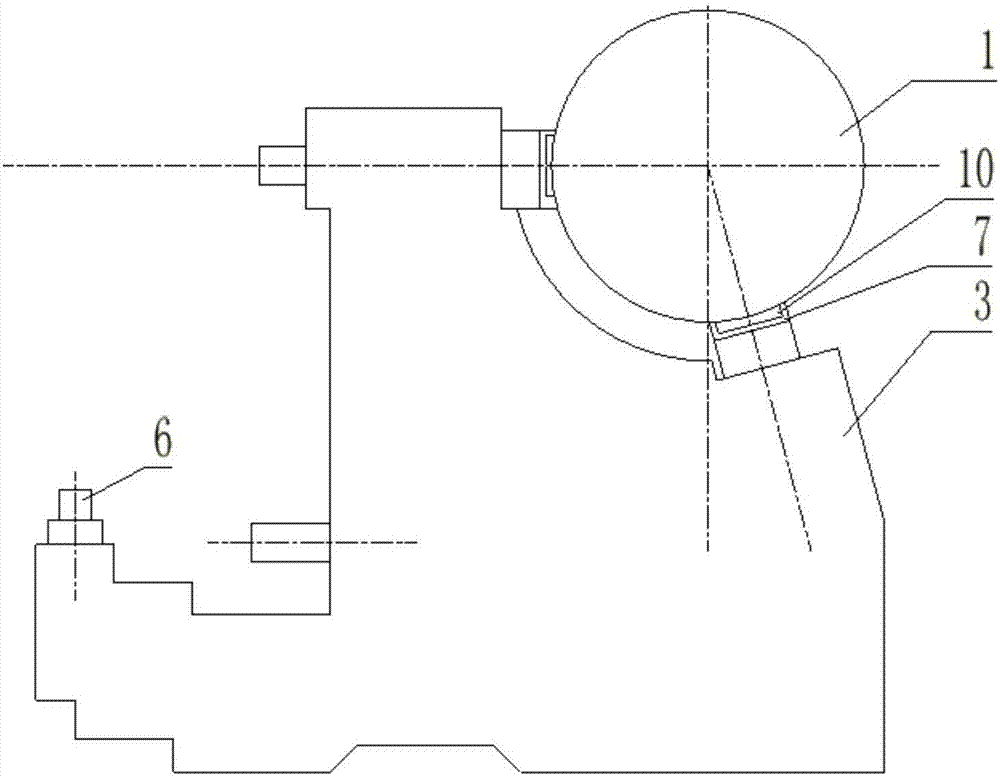

[0043] The invention provides a precision grinding method for the back-up roll of a rolling mill, such as figure 1 with 2 As shown, a roll grinder 4 is used during the implementation of the method. The rail of the roll grinder 4 is equipped with a dynamic and static pressure headstock 2 and a dynamic and static pressure tailstock 3, and the dynamic and static pressure headstock 2 and the dynamic and static pressure tailstock 3 can move back and forth along the guide rail.

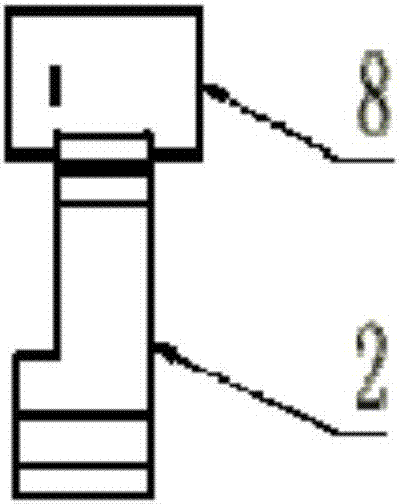

[0044] The roll grinder 4 is fixed on the ground; the dynamic and static pressure headstock 2 and the dynamic and static pressure tailstock 3 are installed relative to each other, and are used to support the supporting roll 1 to be ground; the supporting shoe 10 and the supporting shoe 10 are installed on the dynamic and static pressure headstock 2 It is in contact with the support rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com