Numerical-control linear-rail slide block grinding machine

A technology for sliders and grinding machines, which is applied in the direction of grinding machines, grinding beds, and parts of grinding machine tools. It can solve the problems of the influence of slider dimensional accuracy and the increase of grinding processing errors, and achieve the elimination of grinding processing errors, Effects of improving motion accuracy and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

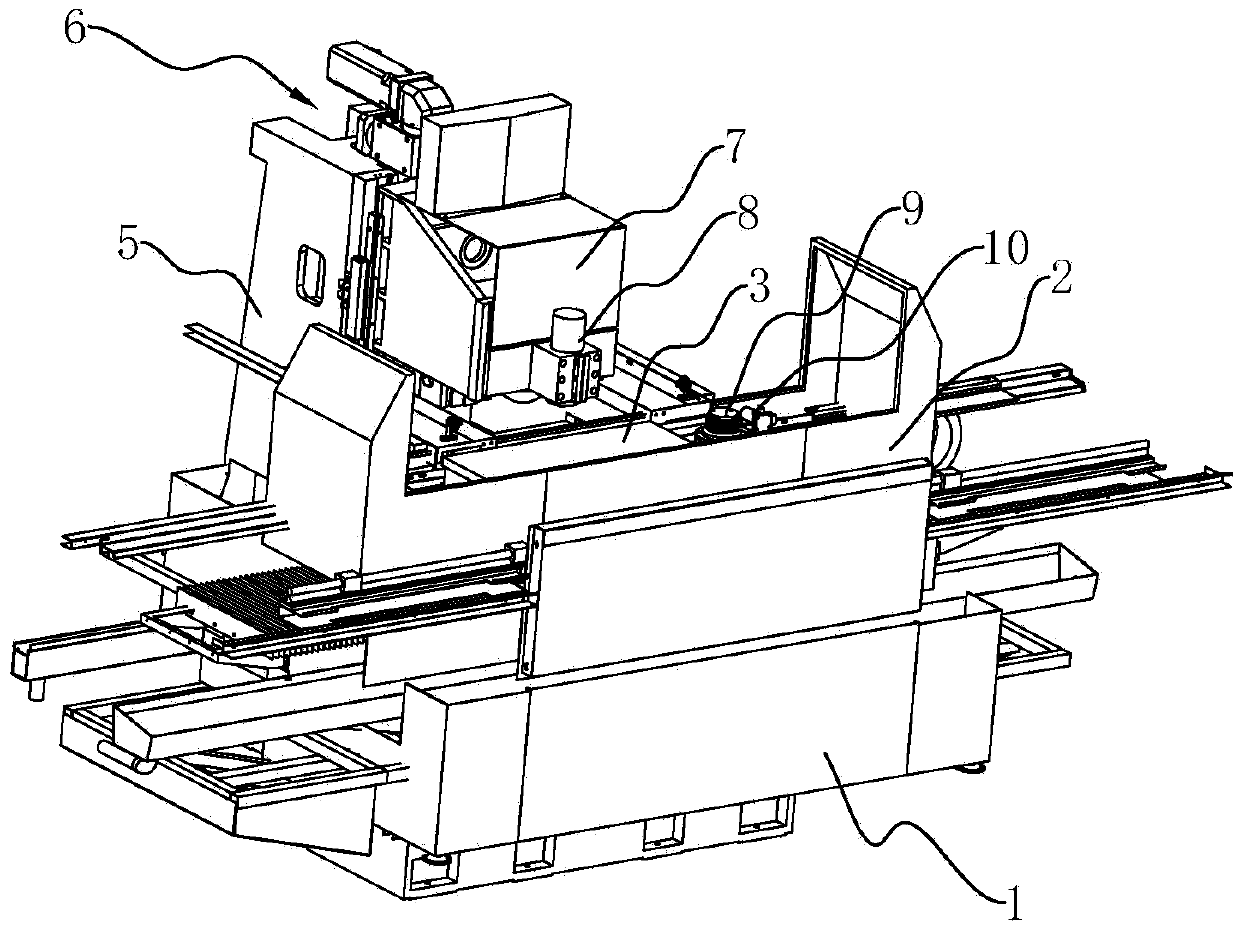

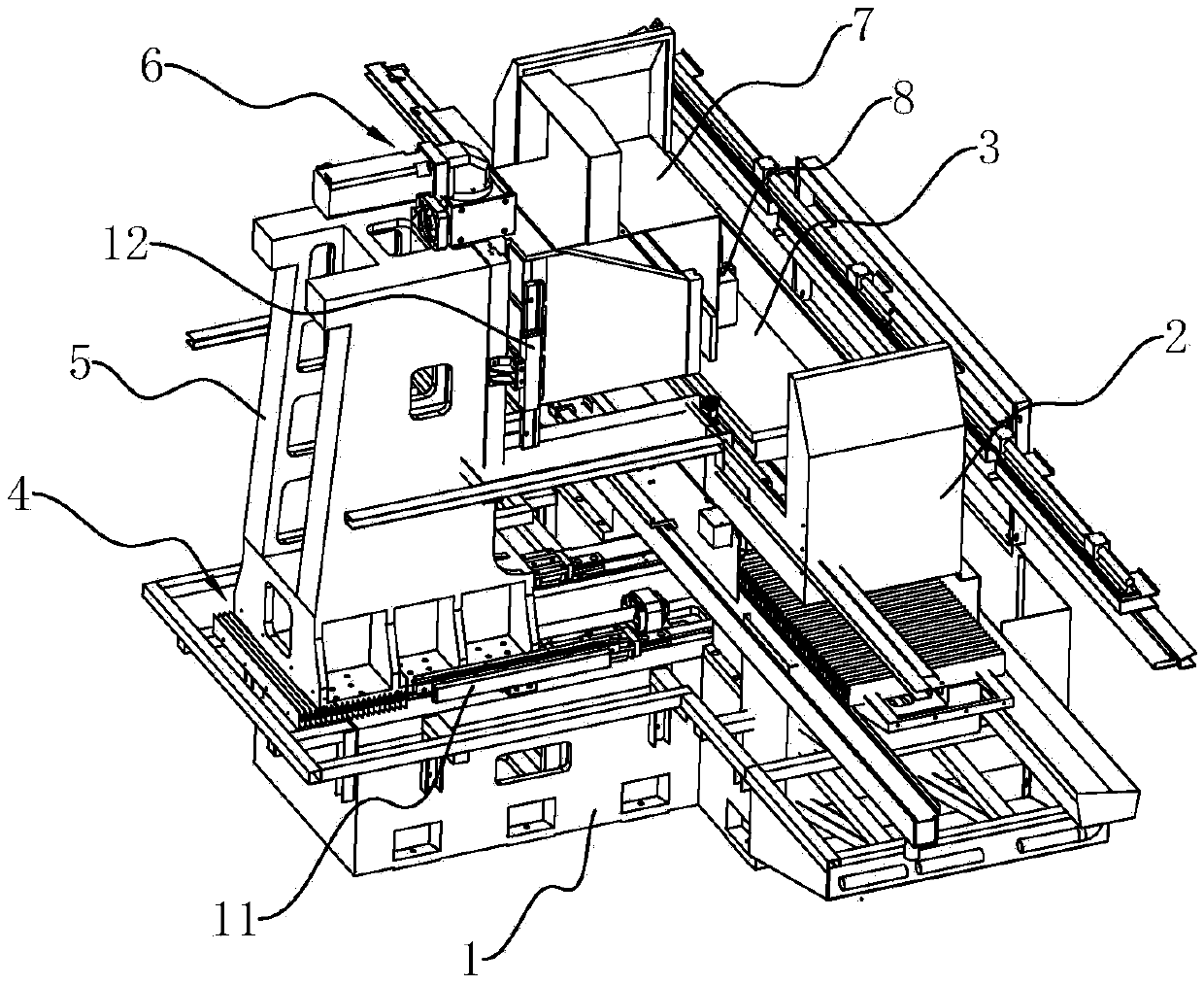

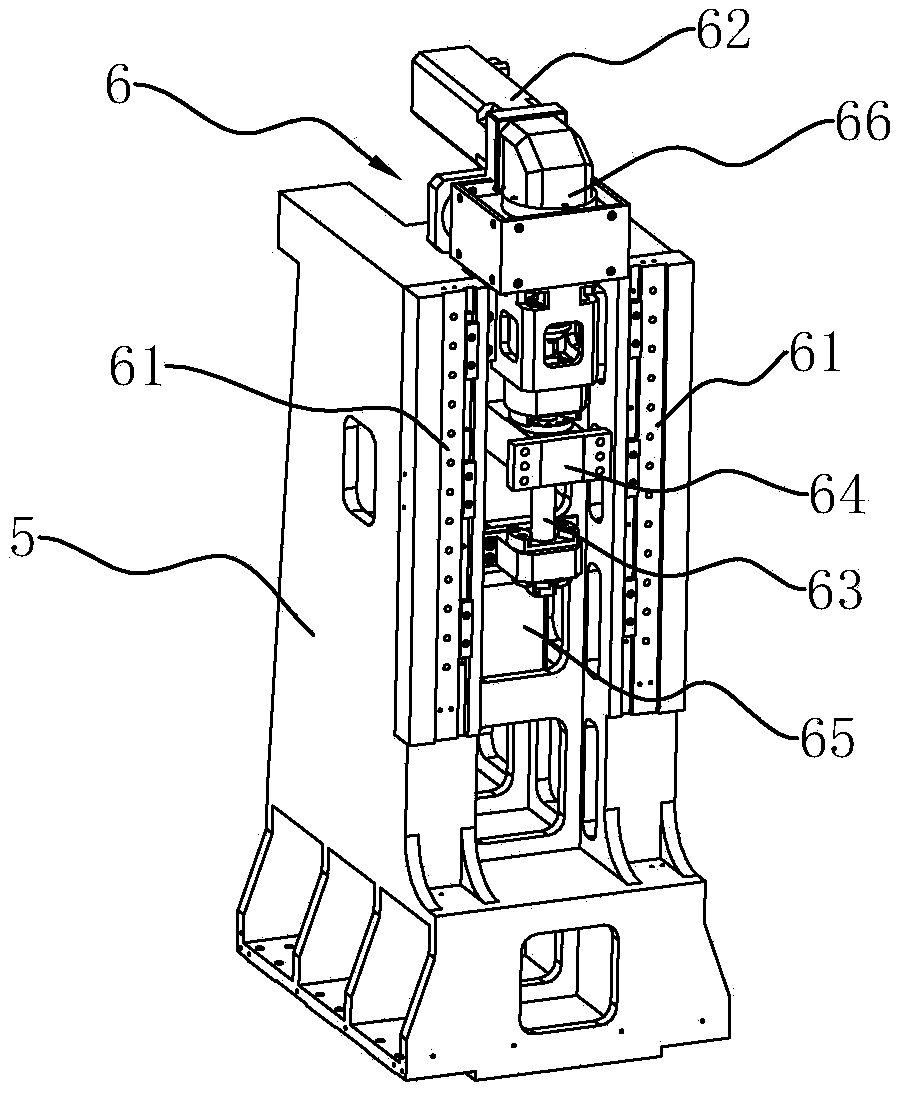

[0015] refer to figure 1 , figure 2 , a CNC line rail slider grinding machine of the present invention, comprising a base 1, on which a grinding table 2 that can move horizontally and horizontally is provided, and the grinding table 2 is installed for fixing the slider The fixture 3, the vertical linear workbench 4 is arranged behind the grinding worktable 2, the support frame 5 is installed on the vertical linear workbench 4, and the vertical linear workbench 6 is arranged on the support frame 5, the vertical linear worktable A horizontal grinding mechanism 7 corresponding to the fixture 3 is installed on the workbench 6 . In this kind of slider grinder, the vertical linear worktable drives the support frame to move as a whole, which greatly improves the rigidity of the grinding mechanism, can avoid the shaking of the grinding mechanism during the processing of the traditional grinder, and effectively eliminates the grinding error. It is beneficial to improve the dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com