Truck steering hydraulic force assisting oil cylinder and production process thereof

A steering hydraulic and truck technology, applied in the direction of fluid steering mechanism, etc., can solve the problems of inability to guarantee the coaxiality of the guide sleeve assembly, the inability to guarantee the coaxiality requirements, the wear of the piston rod and the cylinder barrel, etc., and it is not easy to install firmly. , to ensure the effect of coaxiality and smooth axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

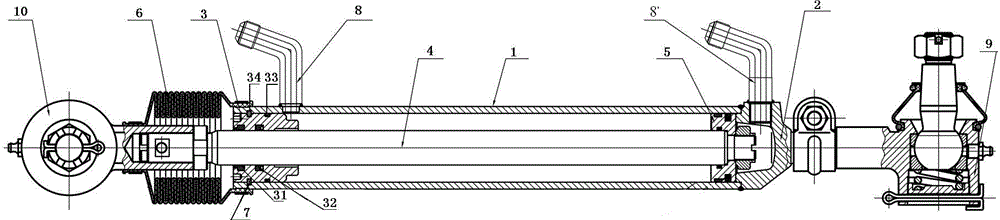

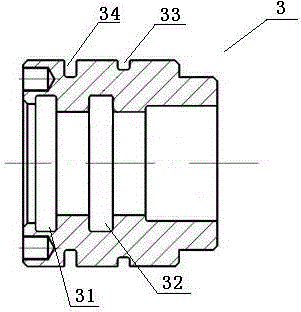

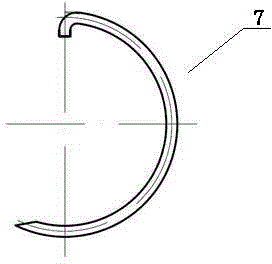

[0031] Truck steering hydraulic booster cylinder products are used for truck double front axle and second axle front wheel steering booster cylinder. The steering booster cylinder is a newly designed and new structure booster cylinder, including cylinder tube 1, support seat 2, guide sleeve 3, piston rod 4. Piston 5, seals, protective cover 6, wire retaining ring 7 and nozzle joint 8, 8 , , Joint Ⅰ assembly 9, joint Ⅱ assembly 10. One end of the cylinder tube 1 is provided with a guide sleeve 3 inside, and the other end is welded with a support seat 2. The guide sleeve 3 and the cylinder tube 1 are connected and fixed by a wire retaining ring 7. The one nozzle joint 8 is welded to one end of the cylinder tube, and the other Nozzle connector 8 , The guide sleeve 3 is welded to the support base 2. The guide sleeve 3 is divided into front and rear parts. The diameter of the front part is larger than that of the rear part. The nozzle connector 8 is aligned with the rear part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com