Automobile plastic spare tire

A technology of plastics and automobiles, which is applied in the direction of wheels, vehicle parts, wheels made of non-metallic materials, etc. It can solve the problems of rubber materials that are not easy to be reused, the fuel economy of automobiles is unfavorable, and the environmental protection requirements are unfavorable, and the fuel economy of automobiles can be improved. , weight reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

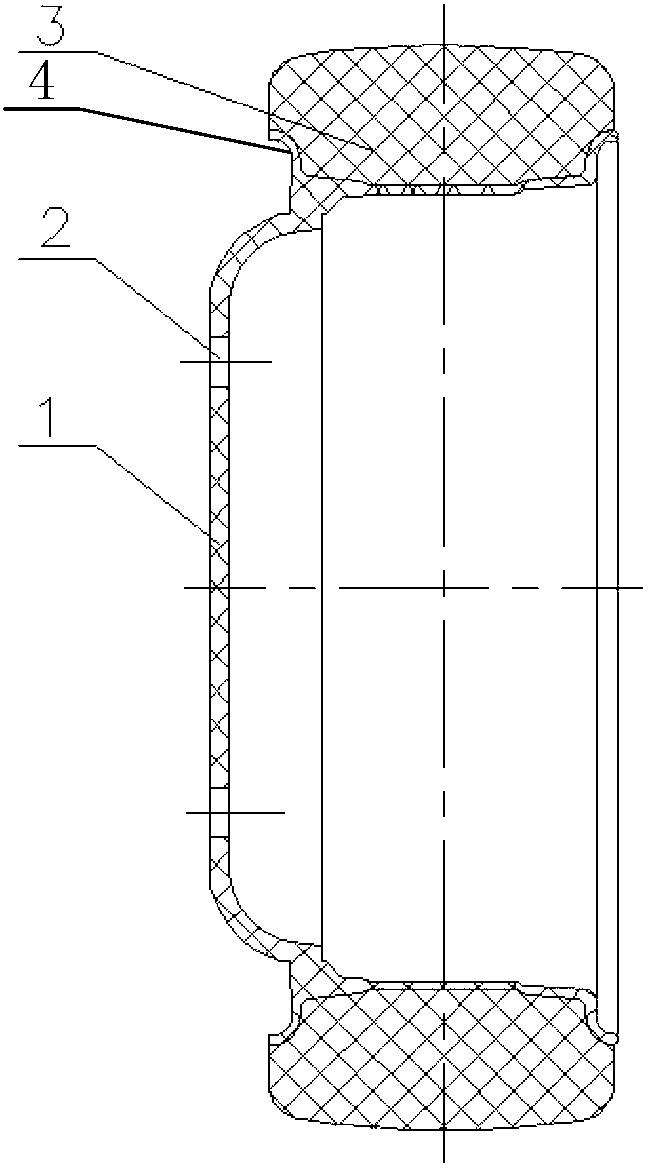

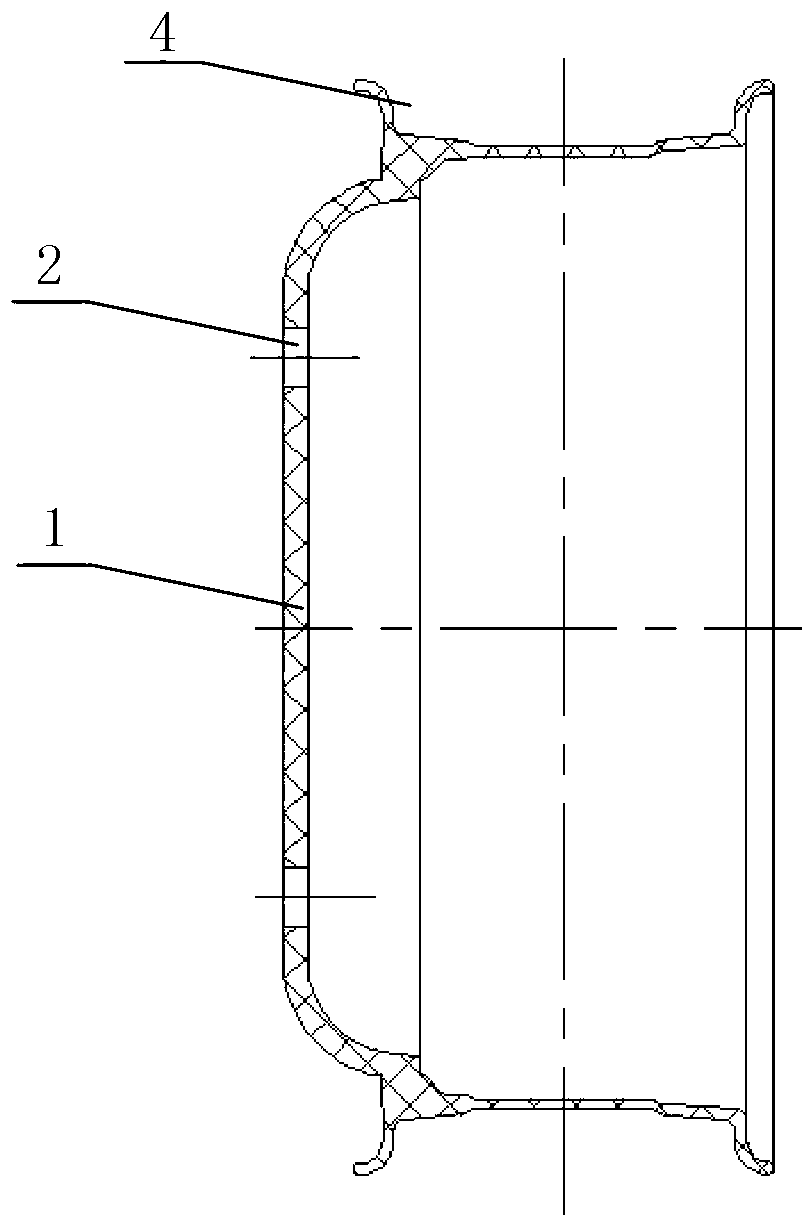

[0017] Embodiment 1: as figure 1 As shown, the automobile plastic spare tire includes a plastic hub 1, the plastic hub 1 is provided with a spare tire mounting hole 2, and a circle of plastic elastomer 3 is provided on the plastic hub 1 outer periphery. This design has a simple structure and does not need to be inflated; secondly, the weight is reduced, which improves the fuel economy of the car. Taking an ordinary car as an example, an ordinary spare tire weighs about 20kg. After changing to a plastic spare tire, it can reduce about 10kg, which can Improve the fuel economy index by about 0.7%. In addition, compared with ordinary rubber spare tire materials, plastic materials can be reused and environmentally friendly; in addition, the price is lower.

[0018] The plastic hub 1 and the plastic elastomer 3 are integrated, so designed, it is easy to process and improve the convenience of use; the outer circumference of the plastic hub 1 is provided with a U-shaped groove 4, and ...

Embodiment 2

[0020] Embodiment 2: as figure 1 As shown, the automobile plastic spare tire includes a plastic hub 1, the plastic hub 1 is provided with a spare tire mounting hole 2, and a circle of plastic elastomer 3 is provided on the plastic hub 1 outer periphery. This design has a simple structure and does not need to be inflated; secondly, the weight is reduced, which improves the fuel economy of the car. Taking an ordinary car as an example, an ordinary spare tire weighs about 20kg. After changing to a plastic spare tire, it can reduce about 10kg, which can Improve the fuel economy index by about 0.7%. In addition, compared with ordinary rubber spare tire materials, plastic materials can be reused and environmentally friendly; in addition, the price is lower.

[0021] The plastic hub 1 and the plastic elastomer 3 are integrated, so designed, it is easy to process and improve the convenience of use; the outer circumference of the plastic hub 1 is provided with a U-shaped groove 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com