Tail door hinge mounting structure

A technology for installing structures and hinges, which is applied to superstructures, subassemblies of superstructures, doors, etc. It can solve the problems of low strength of the installation structure of the hinge of the side-opening tailgate, and achieve a compact structure, easy installation, and uniform force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In different drawings, the same reference numerals are used to indicate the same or similar components, and in addition, words such as "first", "second", "inner", "outer", "top", "portion", "section", "vertical ", "surrounding", "side" and similar terms are only for the convenience of the viewer to refer to the structure in the figure and are only used to help describe the present invention.

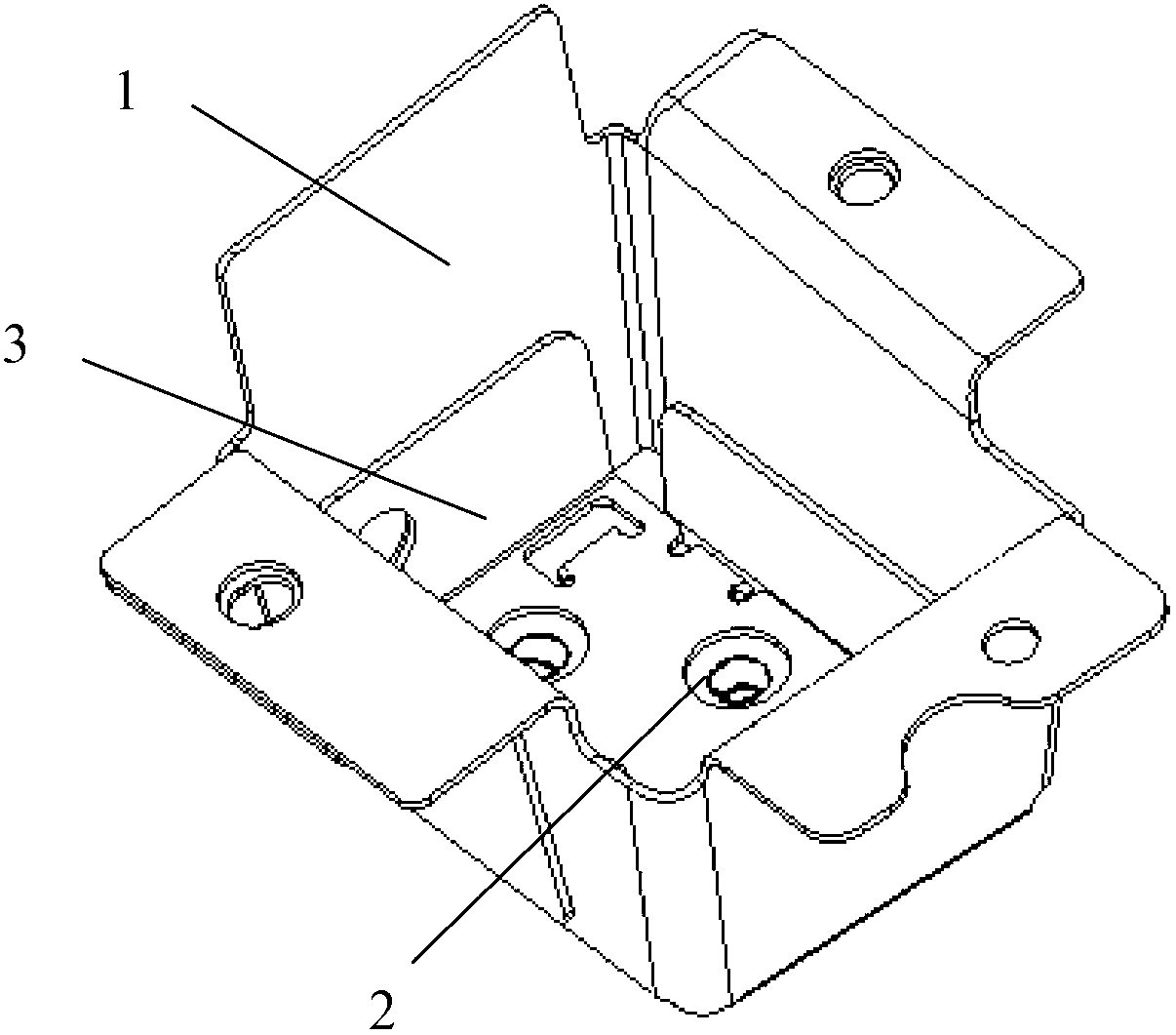

[0034] figure 1 It is a perspective view of an embodiment of the tailgate hinge installation structure of the present invention. Such as figure 1 As shown, the tailgate hinge installation structure includes: installation box 1, nut plate 2, and nut plate cover plate 3.

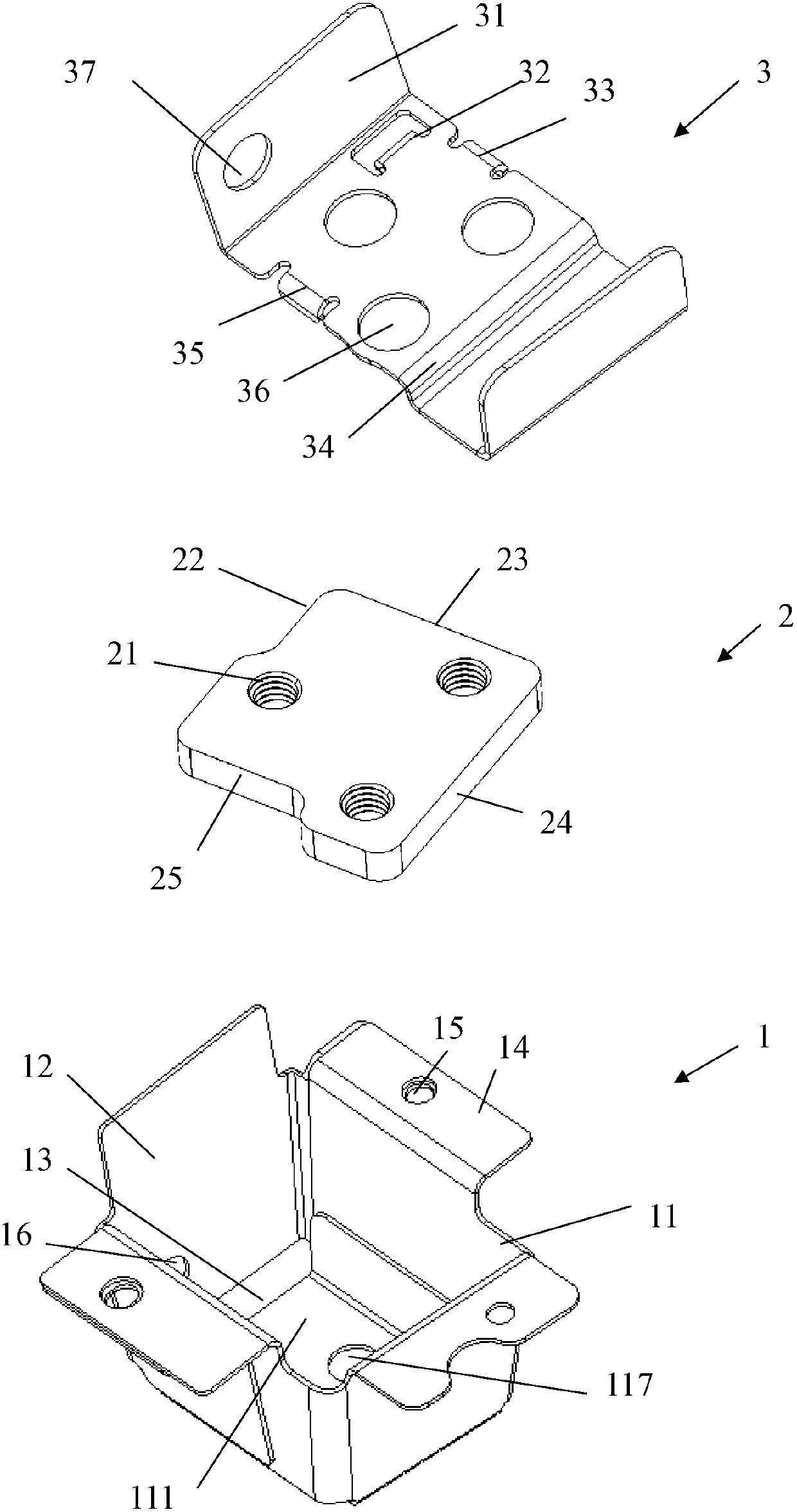

[0035] figure 2 It is a three-dimensional exploded view of an embodiment of the tailgate hinge installation structure of the present invention. Such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com