High-strength connecting structure of front shock absorber front fork tube and motorcycle body

A technology for front shock absorbers and front fork tubes, which is applied to steering mechanisms, bicycle accessories, transportation and packaging, etc. It can solve problems such as breakage, reduce explosive force, and easy breakage of front fork tubes, so as to prevent breakage, increase strength, and The effect that satisfies the requirements of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

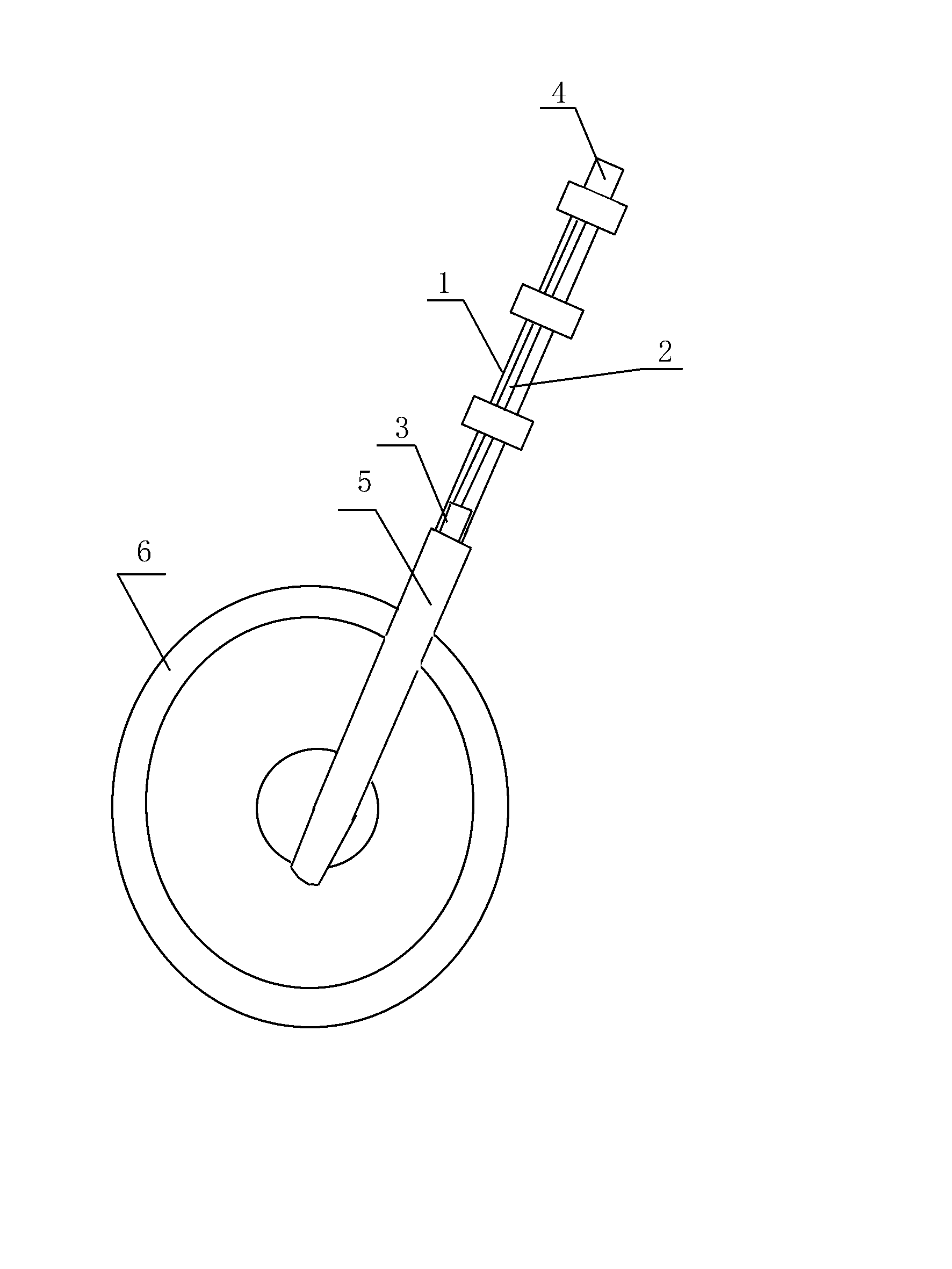

[0008] exist figure 1 Among them, the present invention provides a structure in which the front fork tube of a high-strength front shock absorber is connected to the vehicle body. The front fork tube body 1 described in it is provided with a long tube body, and the front fork tube body 1 is set as a high-precision tube. The wall thickness of the front fork tube body 1 is 2.5 ~ 4.5 mm. The front fork tube body 1 is provided with a piston rod 2, a piston 3 and an air chamber in sequence from top to bottom. The piston 3 is provided with an oil storage cylinder. The front fork tube The upper part of the pipe body 1 is provided with a steering wheel 4, the front fork pipe body 1 is connected with the steering wheel through the steering wheel 4, the lower part of the front fork pipe body 1 is connected with the front wheel 6 through the outer cylinder 5, and the front fork pipe body 1 is inserted into the The inside of the outer cylinder 5 is in sliding fit with the outer cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com