Three-position rotary transceiver

A transceiver device and rotary technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of low automation, occupying a lot of installation space, wasting raw materials, etc., and achieve the effect of high automation, less fault links and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

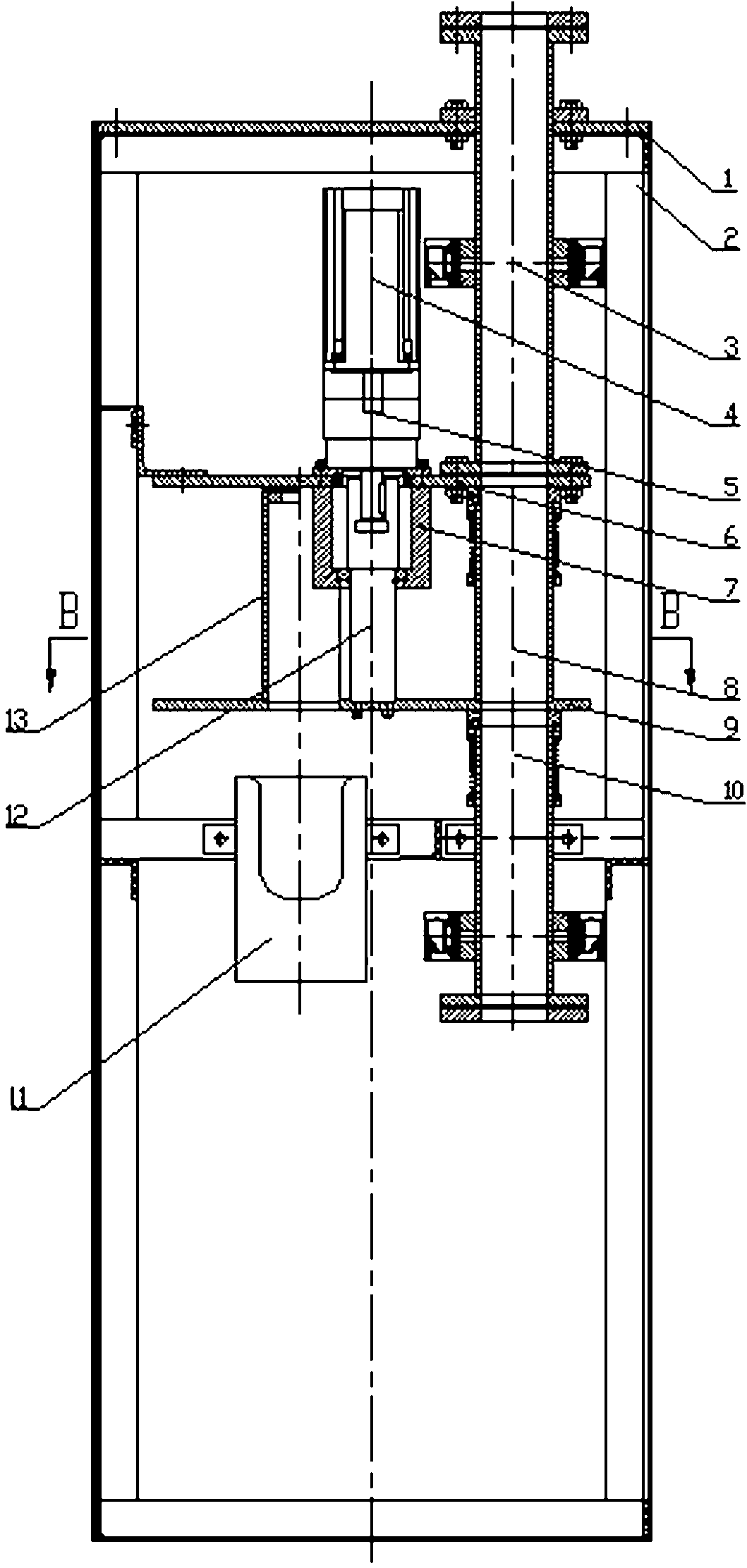

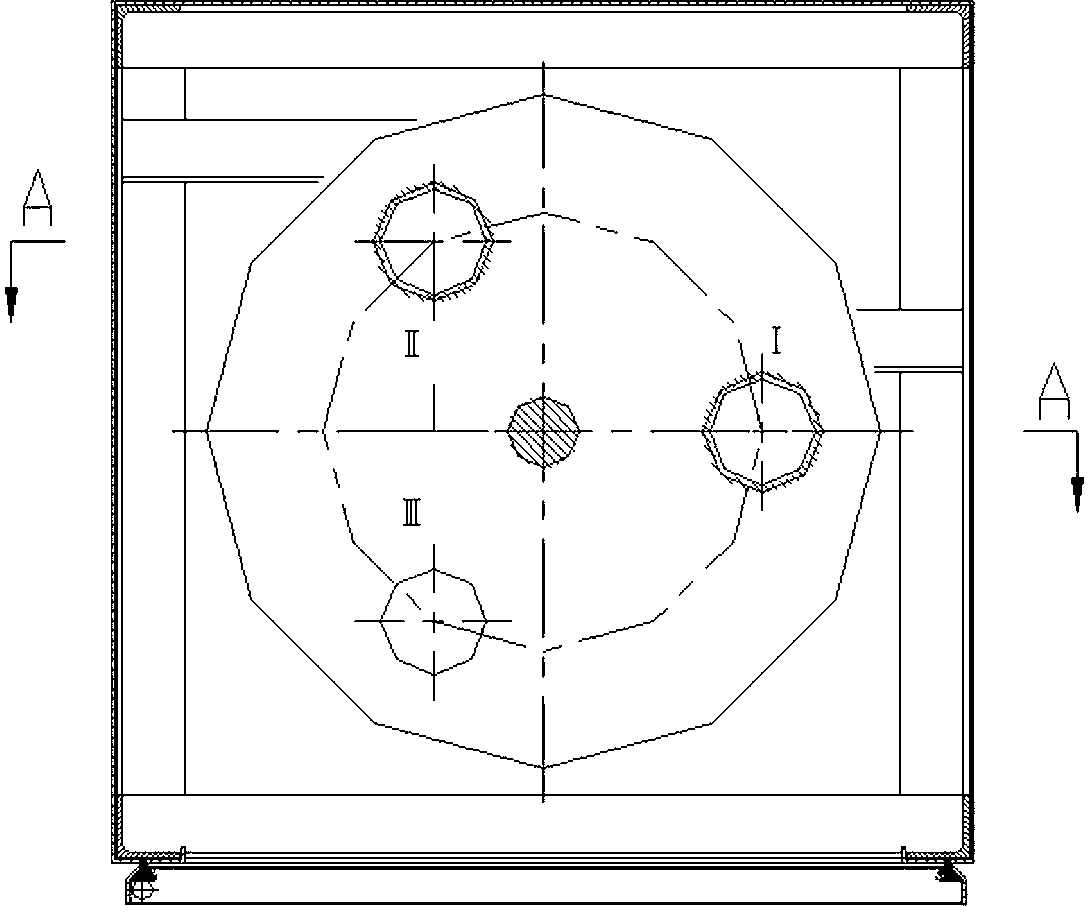

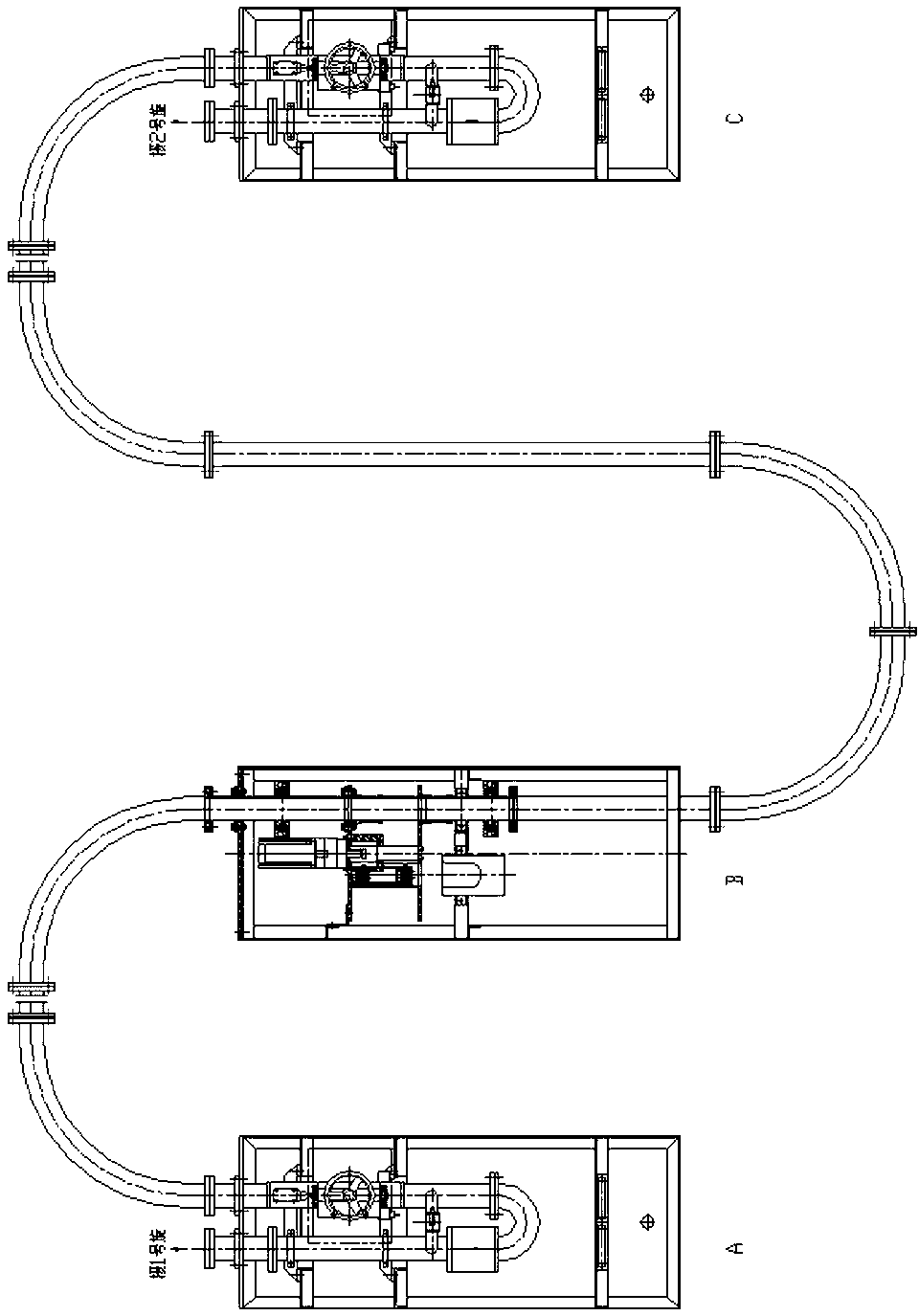

[0014] The structure of the present invention will be described below in conjunction with the accompanying drawings.

[0015] The three-station rotary transceiver device of the present invention includes a cabinet body 2 and a cover plate 1 installed on the cabinet body 2 . The upper plate 6 is fixedly installed in the cabinet body 2, the servo motor 4, the reducer 5 and the bearing support 6 are installed on the upper plate 6, and the connecting shaft 12 connected with the motor and the reducer main shaft is installed on the bearing support 6 , the connecting shaft 12 is fixed on the lower plate 9 . The lower plate 9 is disc-shaped, and three station holes are evenly distributed on it, and these three station holes are all connected with the upper pipe section 3 and the lower pipe section 10 installed in the cabinet body 2 after rotating under the drive of the servo motor 4. It is set concentrically and has the same inner diameter as the upper pipe section 3 and the lower pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com