Automatic sequence gas filling disc special for gas filling substation

An automatic sequence, gas filling sub-station technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problems of increased failure points, single method, high manufacturing and maintenance costs, and achieve reliable automatic opening, reducing The effect of failure links and reducing failure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment of description, the specific embodiment of the present invention is described in further detail:

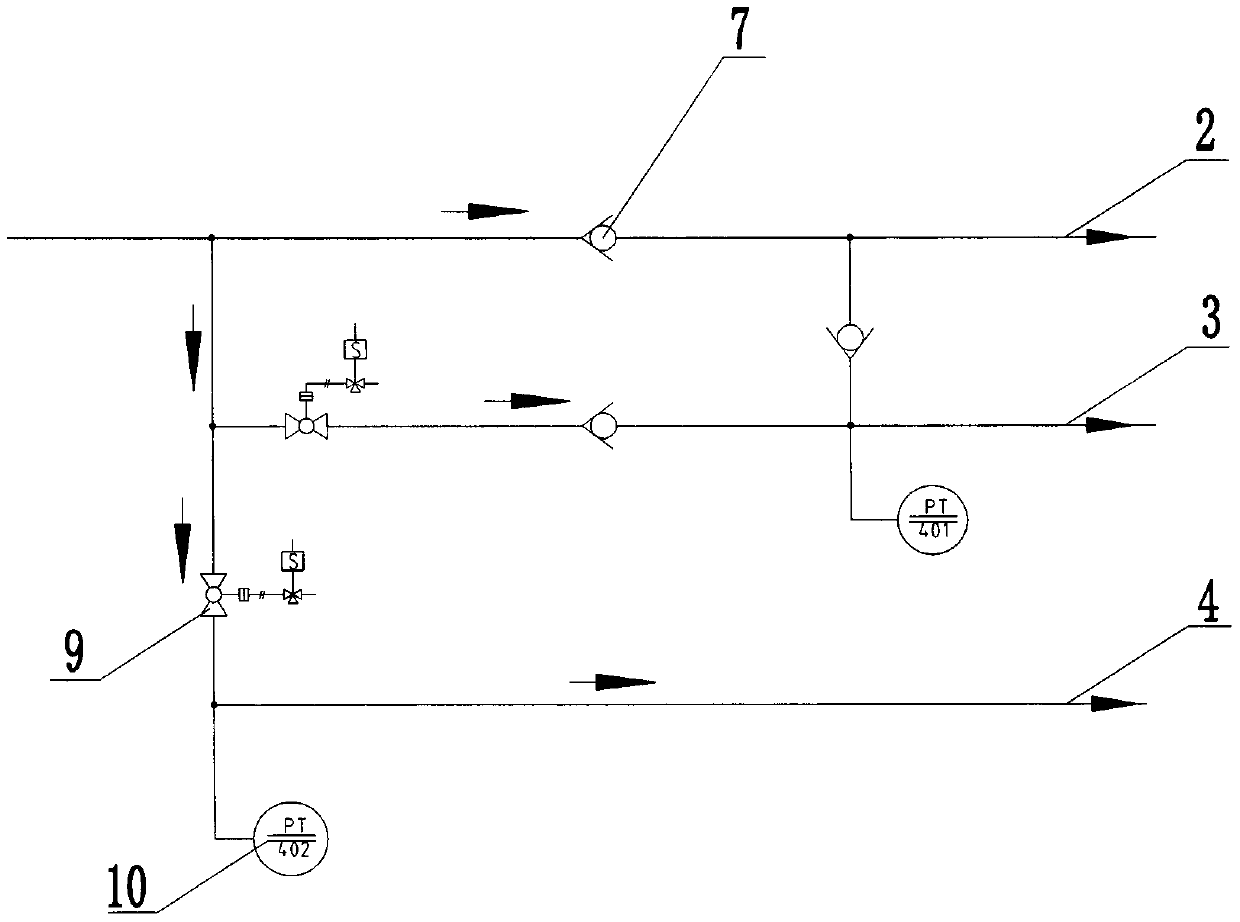

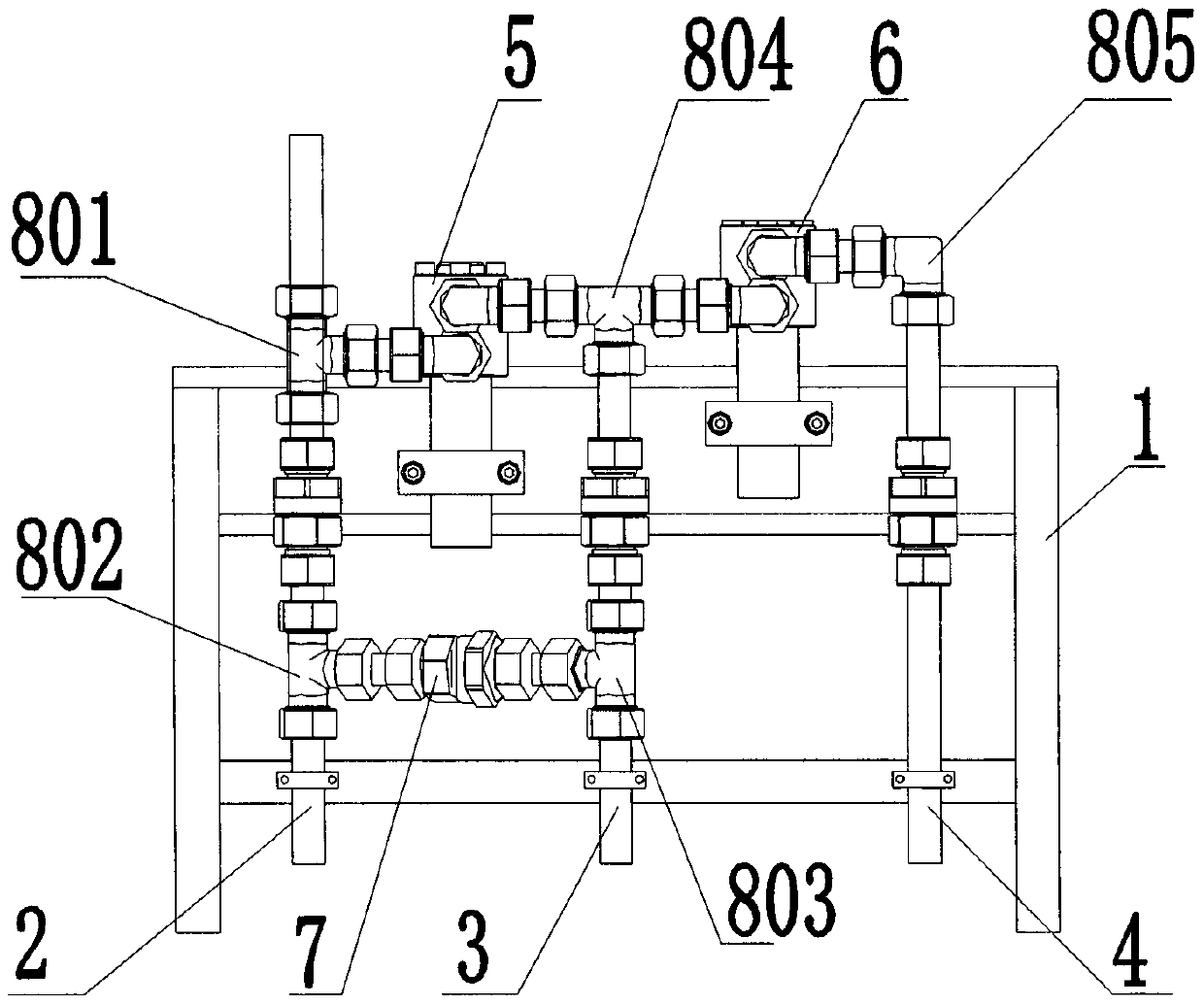

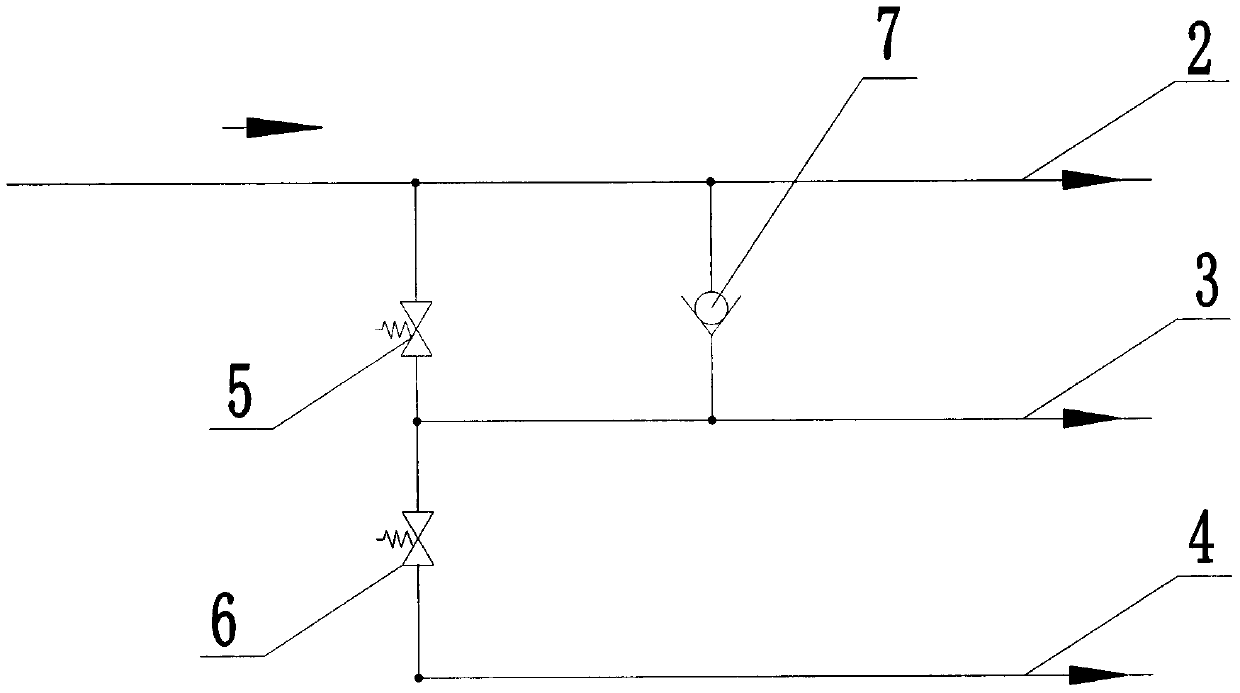

[0018] refer to figure 2 , image 3 with Figure 4 A kind of automatic sequence gas filling tray dedicated to the gas filling sub-station, including a bracket 1 and an inflation pipeline installed on the bracket 1, a self-operated high-pressure sequence valve 5, a self-operated medium-pressure sequence valve 6 and a one-way valve 7. The pipeline includes a direct charging pipeline 2, a high-pressure inflation pipeline 3 and a medium-pressure inflation pipeline 4; the direct charging pipeline 2 is provided with an air inlet joint, a No. 1 tee 801, a connecting pipe fitting, a No. Pass 802 and outlet joint; Described high-pressure inflation pipeline 3 is provided with inlet joint, connecting pipe fittings, No. 3 tee 803 and outlet joint successively from input end to output end; The output end is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com