Textile machine and textile machine system

A mechanical system and fiber technology, used in textiles and papermaking, transportation of filamentous materials, thin material handling, etc., can solve problems such as poor operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, preferred embodiments of the present invention will be described with reference to the drawings.

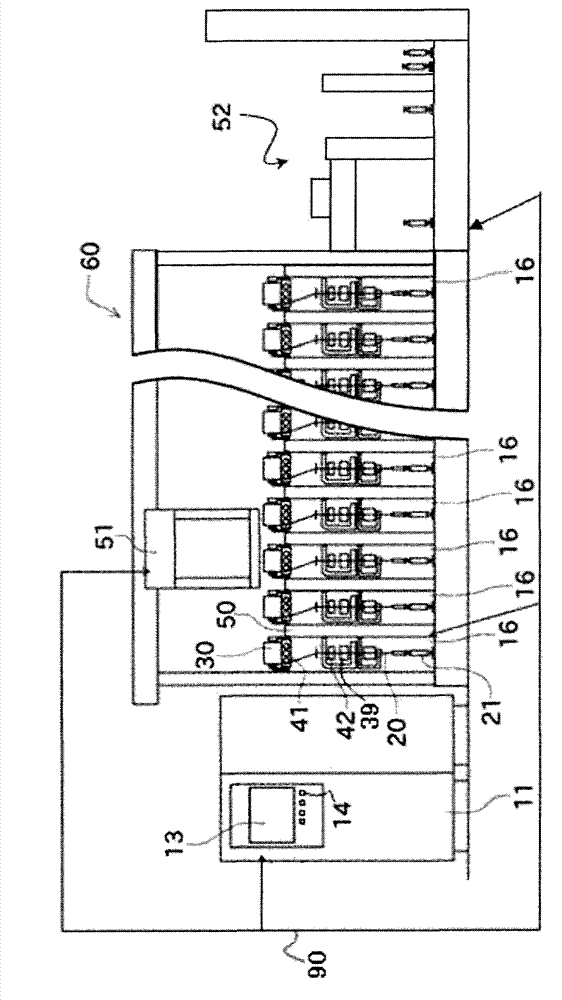

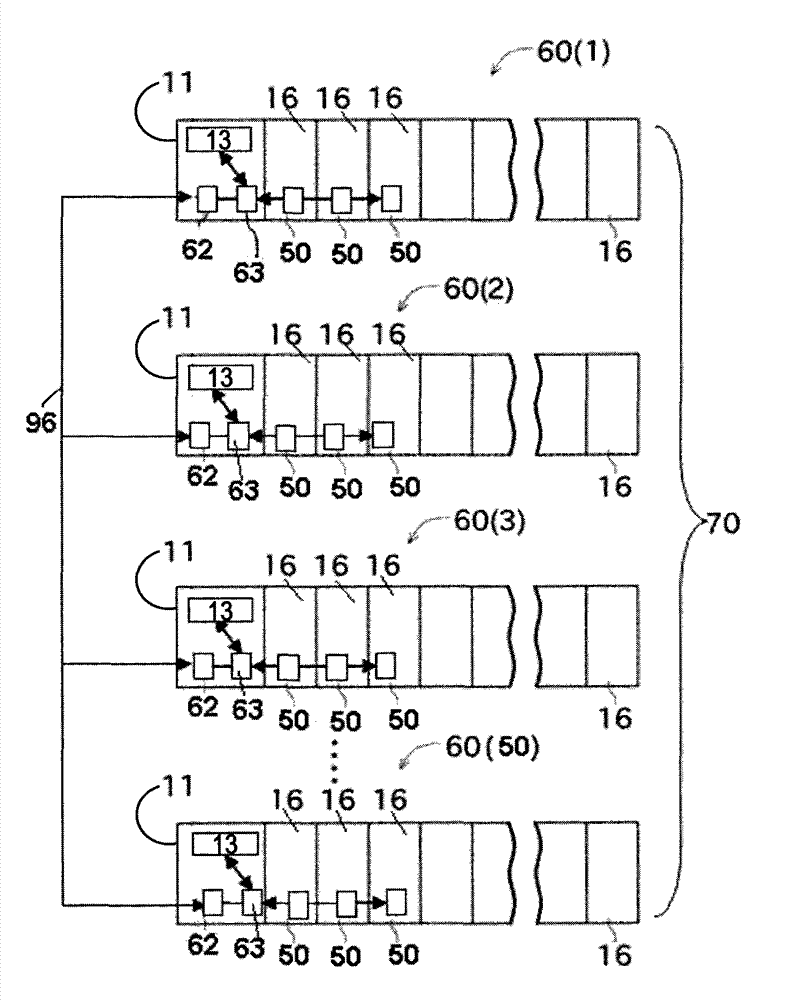

[0038] Such as figure 1As shown, the automatic winder 60 (fiber machine) has: a management device 11; a plurality of winding units (fiber processing units) 16 arranged in parallel; a yarn feeding bobbin supply device 52; and an automatic doffing device 51.

[0039] The yarn supplying bobbin supply device 52 is configured to transport the yarn supplying bobbin 21 along a supply path (not shown) and supply the yarn supplying bobbin 21 to each winding unit 16 . The automatic doffing device 51 is configured to move to the position of the winding unit 16 when the package 30 becomes fully wound in each winding unit 16, and to recover the fully wound package from the winding unit 16 and supply it back. Bobbins of unwound yarn. In addition, the operations of the yarn feeding bobbin supply device 52 and the automatic doffing device 51 are controlled by the machine managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com