Lifting tool for large steel ingot and large forge piece

A technology for steel ingots and forgings, which is applied in the field of hangers for large steel ingots and forgings, can solve the problems of not fully satisfying the lifting operation of large steel ingots and forgings, small bearing capacity, slow operation, etc., to achieve safe and reliable lifting operation and improve productivity. , The effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further detailed description of a hanger for large steel ingots and forgings of the present invention through specific embodiments.

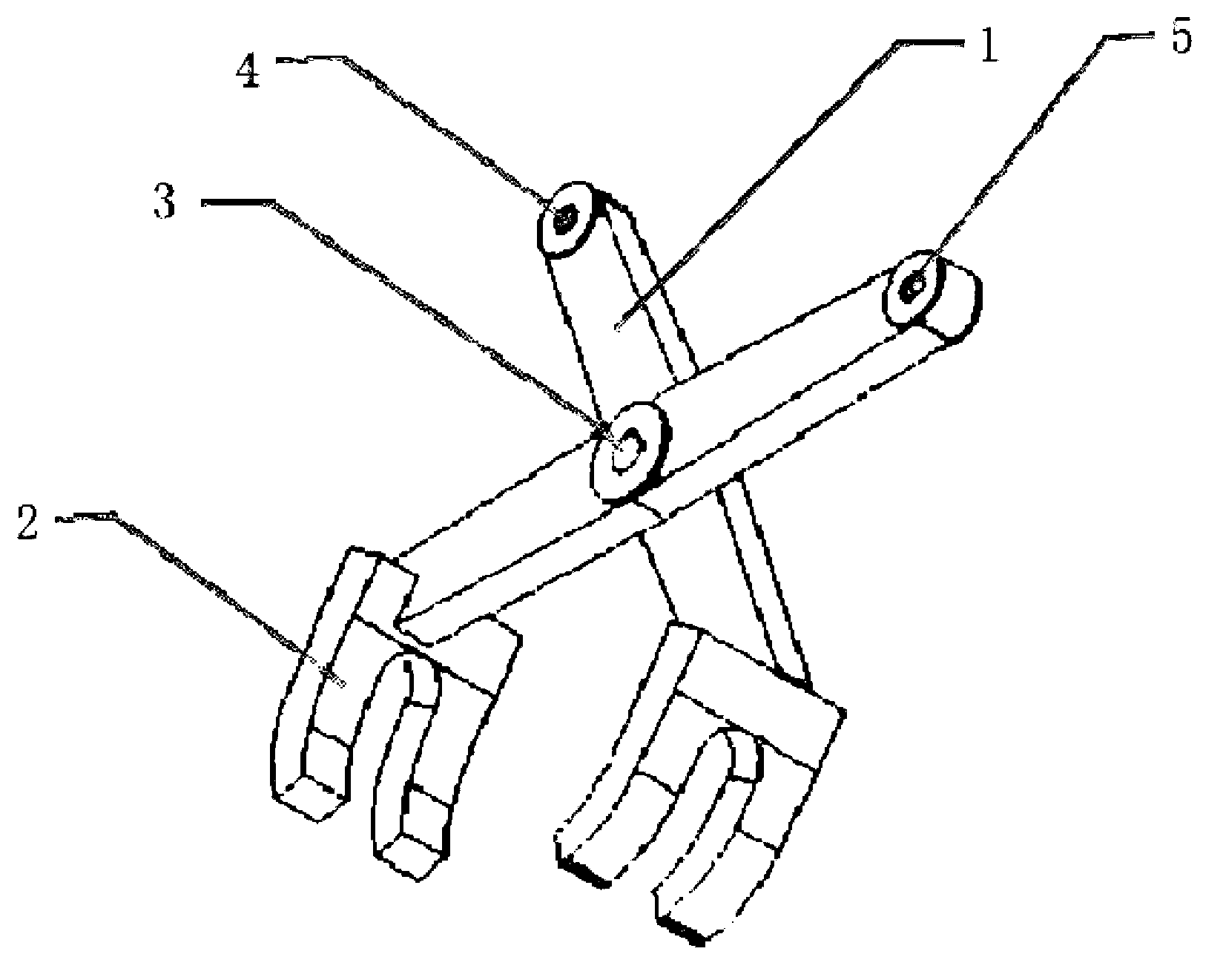

[0016] Such as figure 1 As shown, it includes two pliers arms 1 and two pliers claws 2, the middle parts of the two pliers arms 1 are hinged by the first pin shaft 3, and the lower ends of the two pliers arms 1 are respectively fixedly connected with the two pliers claws 2, and the two pliers arms 1 are fixedly connected to each other. Pin shafts are installed on the upper ends of the pins, respectively the second pin shaft 4 and the third pin shaft 5. Cover plates are installed on the pin shafts, and the two jaws 2 cooperate to clamp large steel ingots and forgings.

[0017] Preferably, the jaws 2 are provided with gaps for clamping the workpiece. In this embodiment, the jaws 2 are U-shaped, and the arms 1 and jaws 2 are made of low carbon steel.

[0018] When hoisting, the auxiliary chain is wound around the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com