Kneading cylinder of kneading machine

A kneading machine and barrel frame technology, applied in the mechanical field, can solve problems such as uneven force, easy wear, and need for high-power motors, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

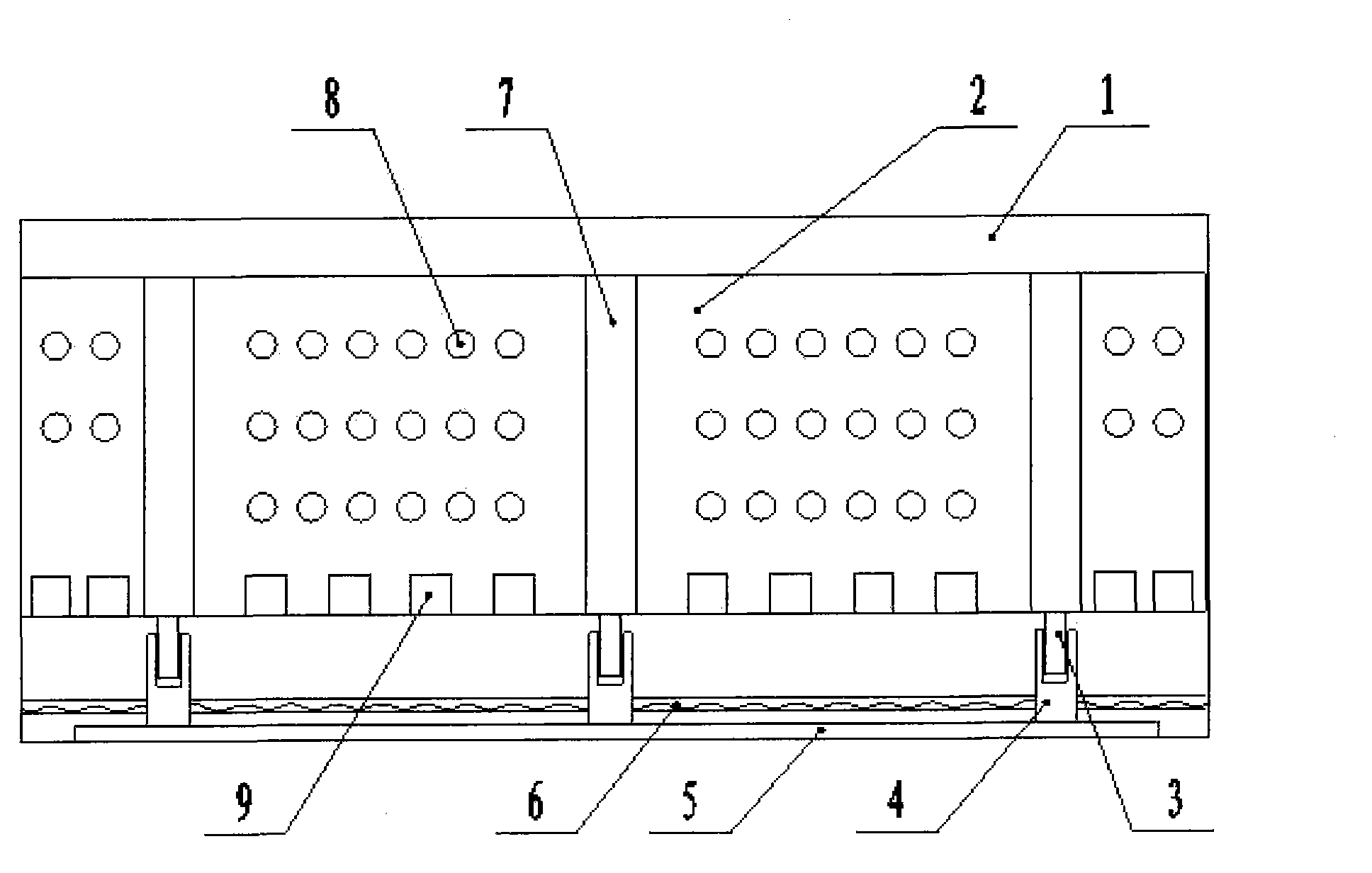

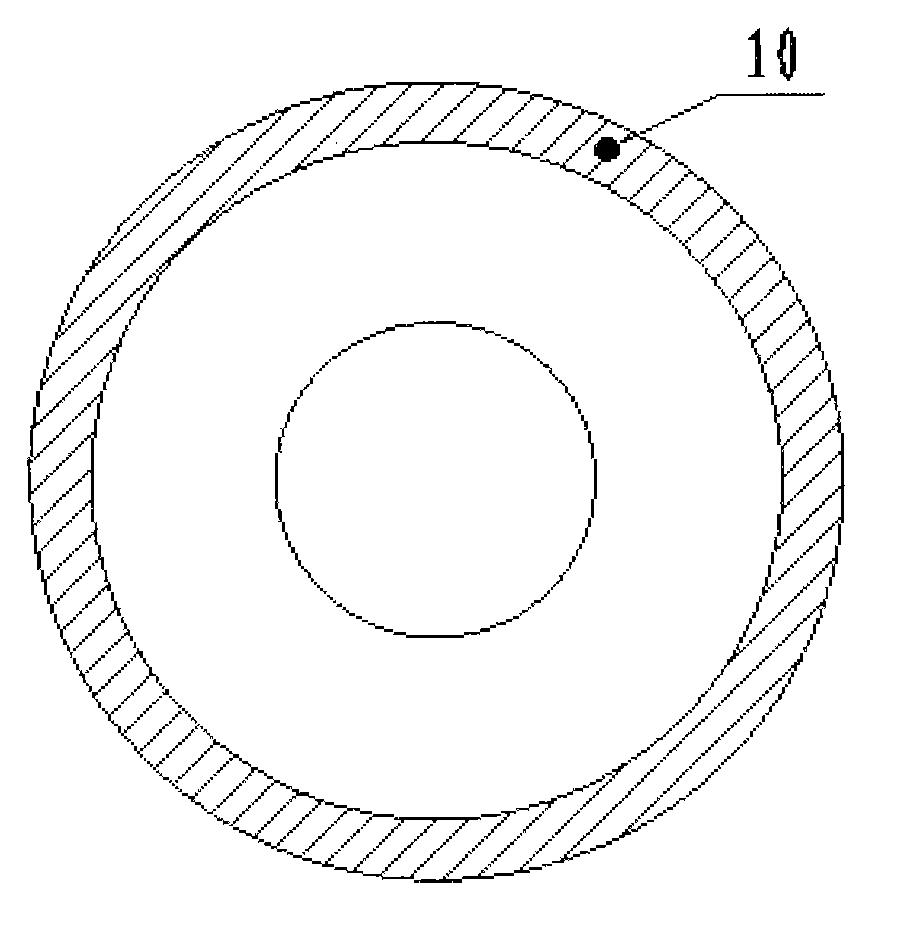

[0014] As shown in the figure, the kneading machine rubs the cylinder, which includes a cylinder holder 1, a kneading cylinder 2, an orbital wheel 3, and an orbital wheel bracket 4. The cylinder holder 1 is provided with a track 5 for fixing the orbital wheel bracket 4, and the orbital wheel bracket 4 There is a synchronous screw rod 6 between them, and the track wheel 3 is arranged on the track wheel bracket 4; the kneading cylinder 2 is arranged in the cylinder frame 1, and the kneading cylinder 2 is provided with a raceway 7 meshing with the track wheel 3, and the kneading cylinder 2 has a uniform wall. Several rows of air inlets 8 and a row of cloth guide rods 9 are provided.

[0015] As shown in the figure, the kneading cylinder 2 is provided with an air inlet 8 and a cloth guide rod 9, hot air can enter through the air inlet 8 to warm the leather, and the cloth guide rod 9 can significantly improve the effect of the thermal kneading of the kneading machine.

[0016] As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com