Flow guiding and fracturing method

A technology of diversion pressure and fracturing, which is applied in the direction of chemical instruments and methods, production fluids, earthwork drilling and production, etc. It can solve the problem that the concentration of proppant section reduces the height of proppant column, it is difficult to ensure proppant, and there is no obvious boundary between flow channels, etc. problems, to achieve the effect of being conducive to flowback, realizing production capacity, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

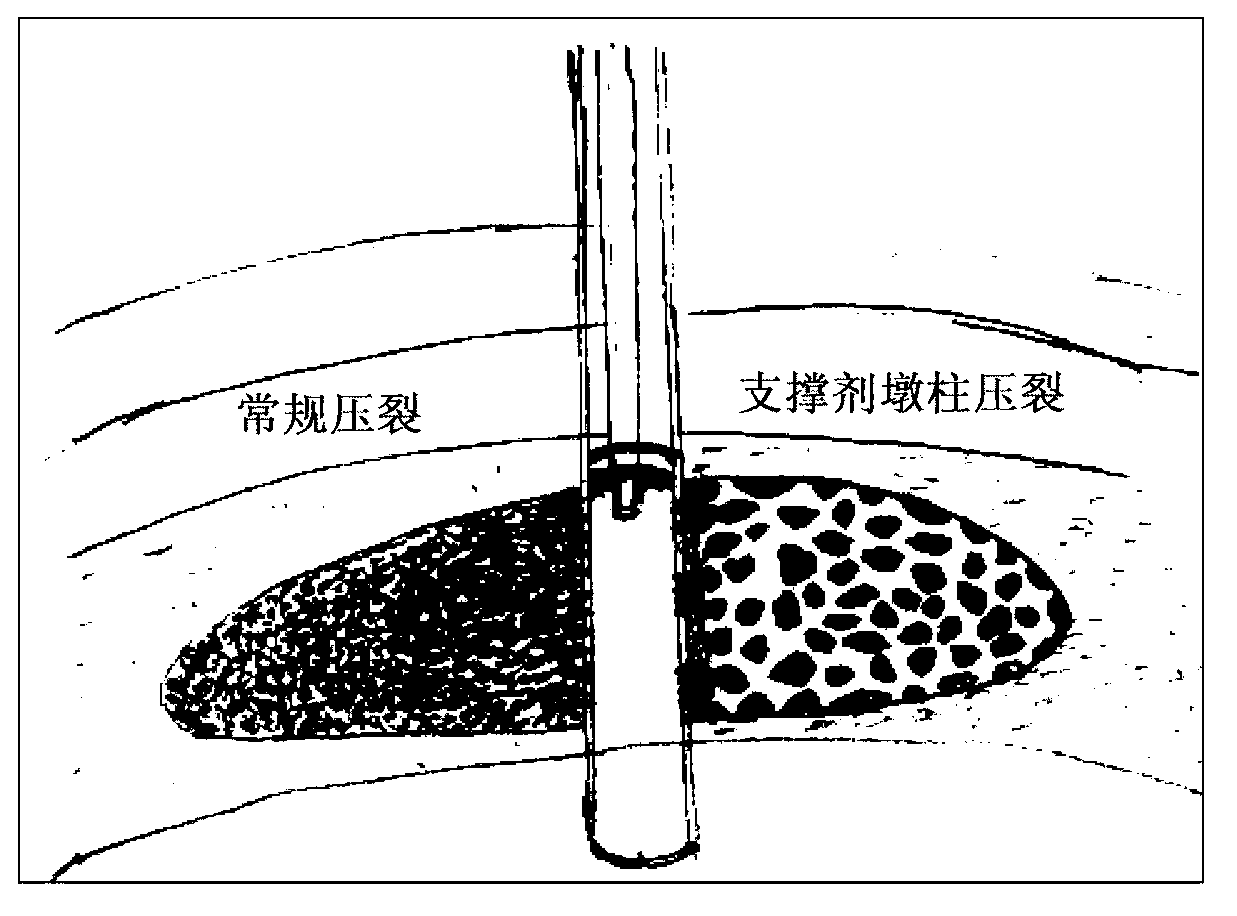

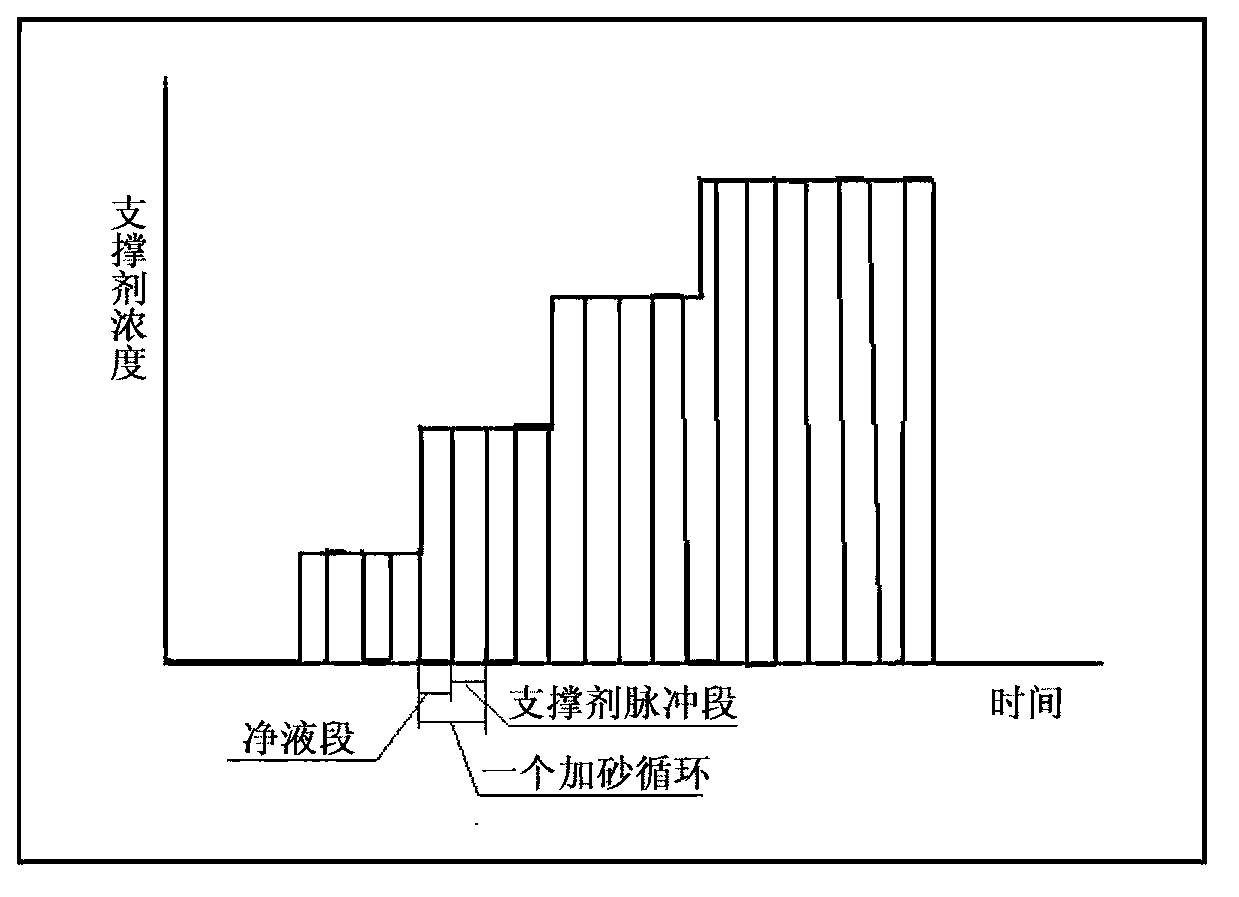

[0026] In order to eliminate the dependence of fracture conductivity on proppant performance, the invention adopts special technological means to build open channels in fractures to form higher fracture conductivity and smoother reservoir fluid channels. This process enables proppant to be placed non-uniformly in the fracture in the form of pillars (see figure 1 ). Here the proppant no longer acts as a diversion medium, but as a support to prop up the fracture wall around the channel. The formation of channels in fractures is a combination of specific perforation schemes, pumping procedures, and fracturing fluid design.

[0027] In order to place proppant non-uniformly in the fracture in the form of proppant pillars, the present invention employs a fracturing procedure as described below.

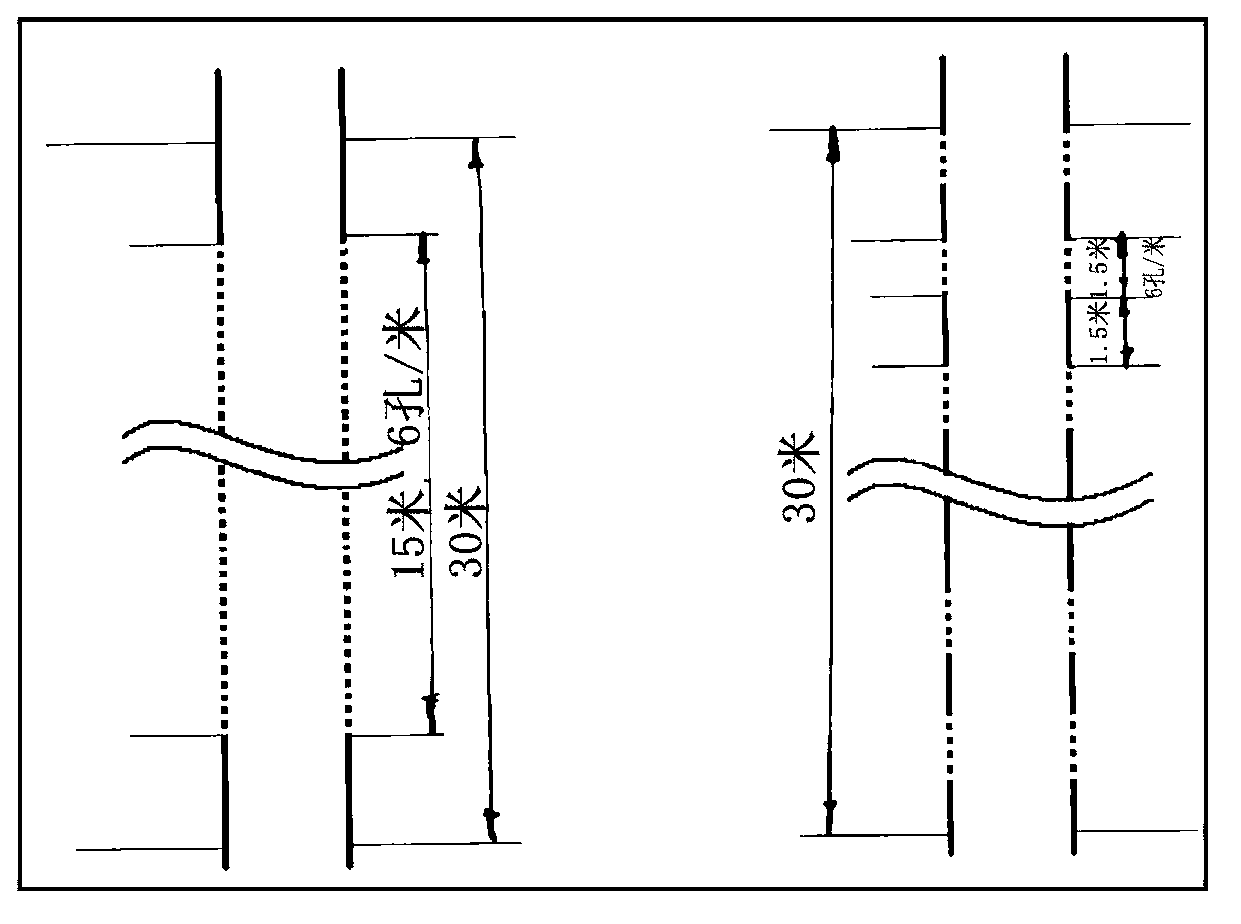

[0028] (1) Perforation scheme: use non-uniform perforation consisting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com