Electromagnetic valve driving device capable of carrying out online regulation

A solenoid valve driven, low-pressure driven technology, applied in the direction of fuel injection devices, charging systems, engine components, etc., can solve the problems of error-prone, time-consuming, troublesome modification process, etc., and achieve the effect of improving work efficiency and reducing test workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

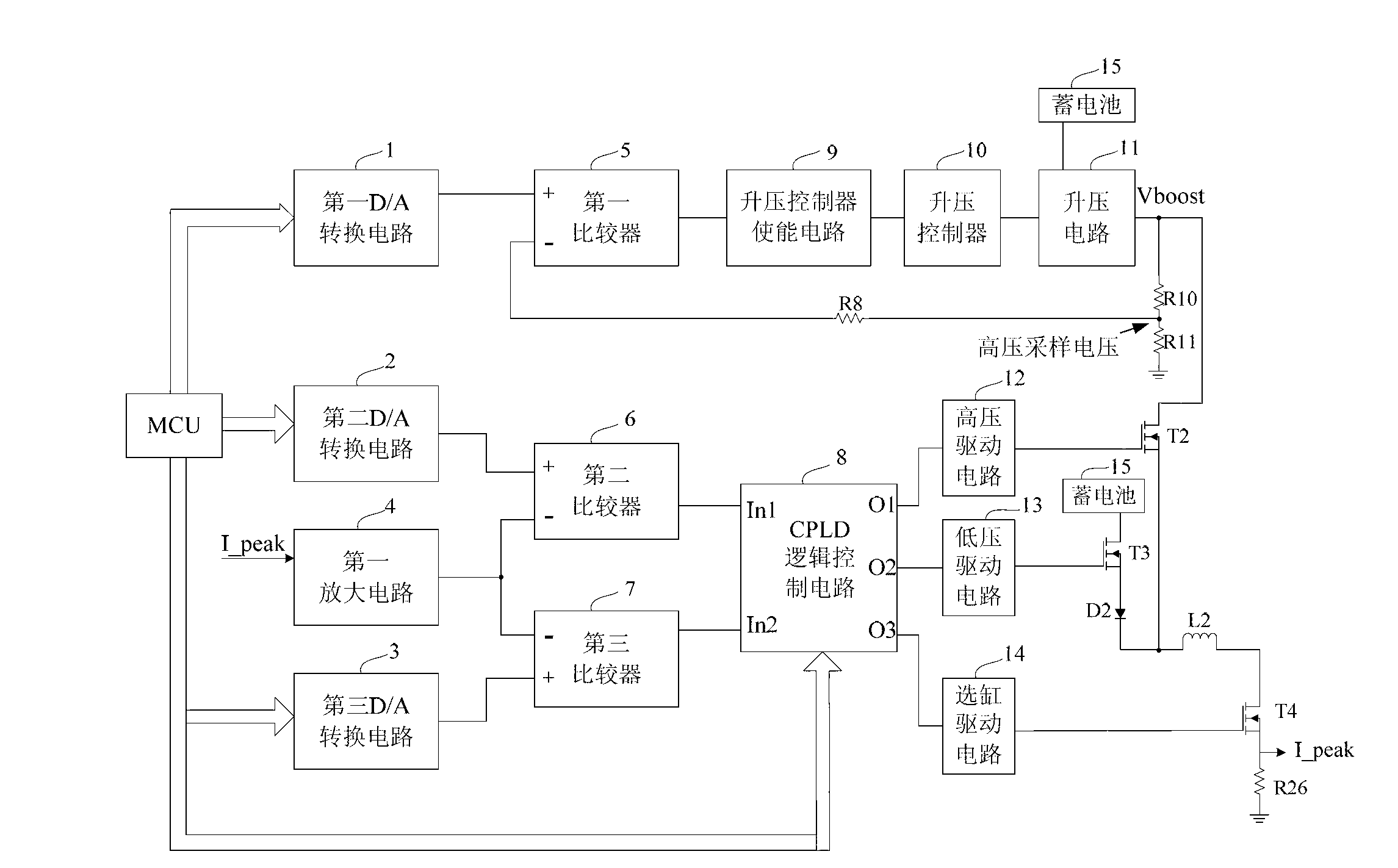

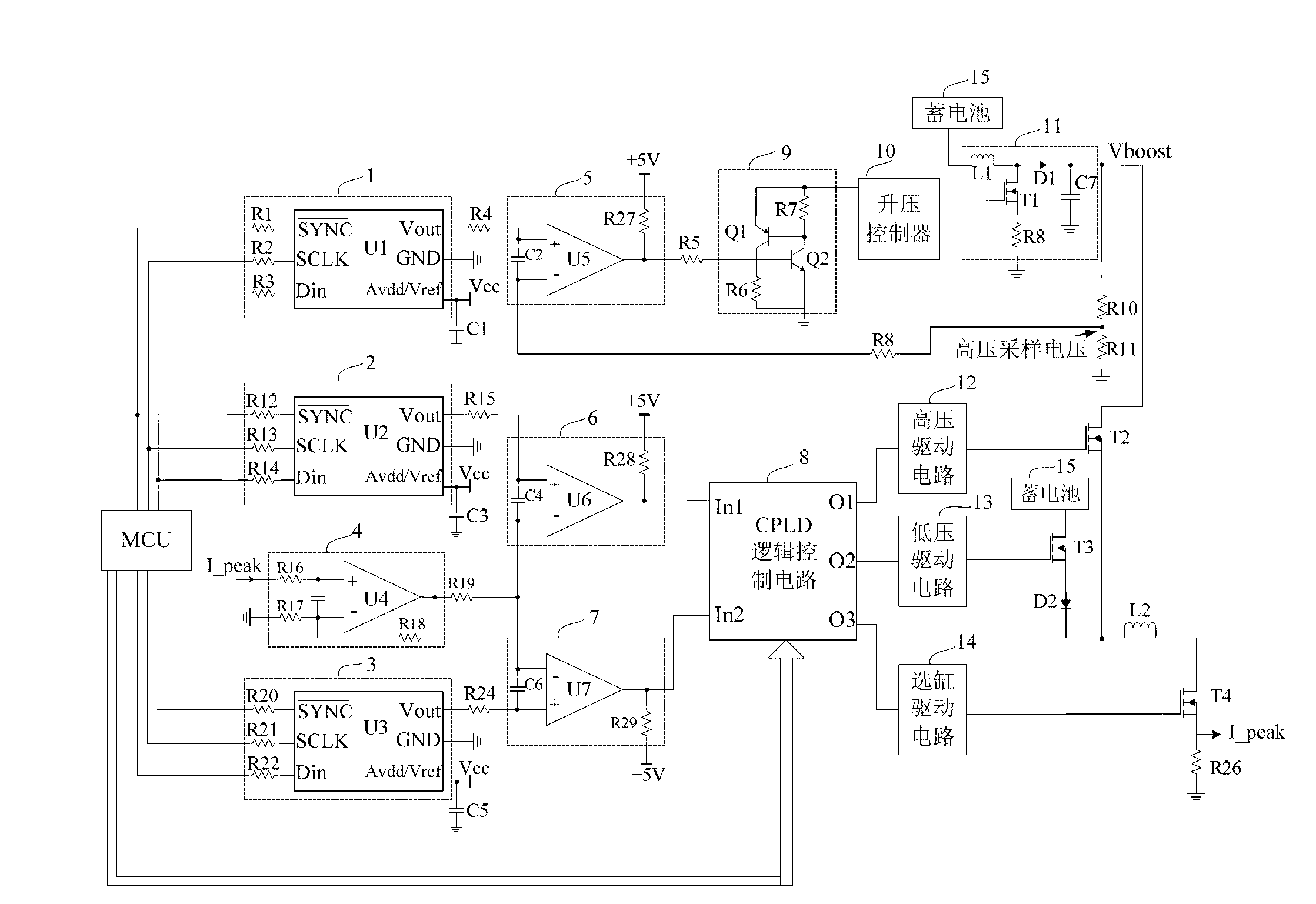

[0024] Such as figure 1 , figure 2 Shown:

[0025] A solenoid valve drive device capable of online adjustment, including MCU, and also includes a first D / A conversion circuit 1, a second D / A conversion circuit 2, a third D / A conversion circuit 3, a first amplifying circuit 4, a second D / A conversion circuit A comparator 5, a second comparator 6, a third comparator 7, a CPLD logic control circuit 8, a boost controller enabling circuit 9, a boost controller 10, a boost circuit 11, a high voltage drive circuit 12, a low voltage drive Circuit 13, cylinder selection drive circuit 14, high voltage drive tube T2, low voltage drive tube T3, cylinder selection tube T4, sampling resistor R26.

[0026]The MCU is connected to the first D / A conversion circuit 1, the second D / A conversion circuit 2, the third D / A conversion circuit 3 and the CPLD logic control circuit 8;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com