Ejector and water heater with same

A technology of jet and water heater, applied in the field of water heater and solar water heater, can solve the problems of large installation space and unsightly appearance, and achieve the effect of solving the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

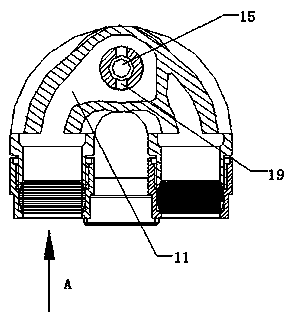

[0040] Such as Figure 1-Figure 3 As shown, this embodiment provides an eductor, including a shell body 1, the shell body 1 has a cold water chamber 11 adapted to communicate with the cold water inlet pipeline 2, and is located in the same plane as the cold water chamber 11 and A hot water chamber 12 with a common side wall and adapted to communicate with the hot water inlet pipeline 3, a jet channel 14 located on the common side wall and leading from the cold water chamber 11 to the hot water chamber 12 And the jet port 15 arranged at the end of the jet channel 14 at the hot water chamber 12, the diameter of the jet port 15 is smaller than that of the jet channel 14, and the jet port 15 communicates with the user port.

[0041] In this embodiment, the jet port 15 is a tapered hole, and the tapered hole passes the jet through the small opening. Of course, the jet port 15 can also be set in other regular or irregular shapes, as long as the diameter of the jet port 15 is smalle...

Embodiment 2

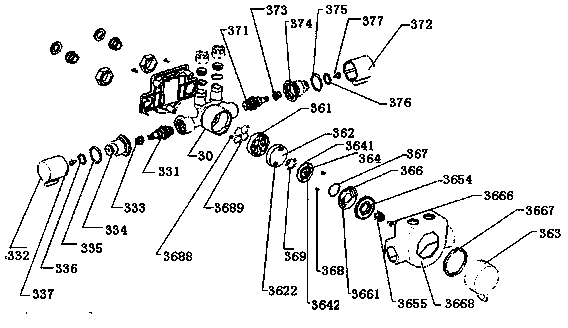

[0046] Such as Figure 9 , Figure 10 with Figure 11 As shown, this embodiment provides a schematic structural diagram of another ejector. The difference between this jet device and the jet device described in Embodiment 1 is: first, the jet injection port 15 is fixed on the jet channel 14 by bolts, and here, the bolt fixing is only a specific example of the detachable fixing method, The jet injection port 15 can also be fixed with the jet channel 14 in other detachable ways, for example, by screwing the jet injection port 15 with the jet channel 14 itself; The pipe 20 and the diameter reducing pipe 21 communicating with the throat pipe 20 flow to the user port. The diameter of the end of the diameter reducing pipe 21 facing the user port is large. A backup pressure is formed at the outlet of 21, so that a backflow phenomenon occurs after the negative pressure zone of the way is formed.

Embodiment 3

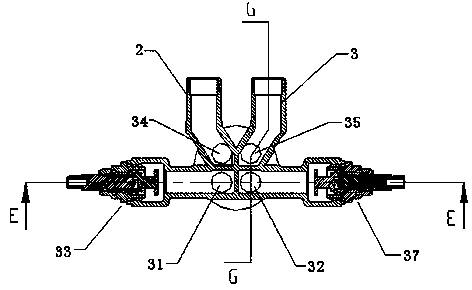

[0048] Such as Figure 4 As shown, the present embodiment is a drop-type solar water heater comprising the ejector described in Embodiment 1, the solar water heater mainly includes three parts, the first part is the ejector described in Embodiment 1, and the ejector The cold water chamber 11 and the hot water chamber 12 are adapted to communicate with the cold water inlet pipeline 2 and the hot water inlet pipeline 3 respectively; the second part is the cold water inlet pipeline communicated with the cold water chamber 11 and the hot water chamber The hot water inlet pipeline communicated with the chamber 12; the third part is able to communicate with the cold water inlet pipeline 2 and the hot water inlet pipeline 3, and is used to provide cold water and hot water to the ejector, and the flow rate of cold water and hot water And the double linkage control valve that controls the temperature of the mixed cold water and hot water.

[0049] The structure of the dual linkage con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com